Porous light-weight carbon-based biological carrier and preparation method thereof

A biological carrier, lightweight technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. Large, complex processing technology and other problems, to achieve the effect of easy quantity, improved adsorption capacity and film hanging amount, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

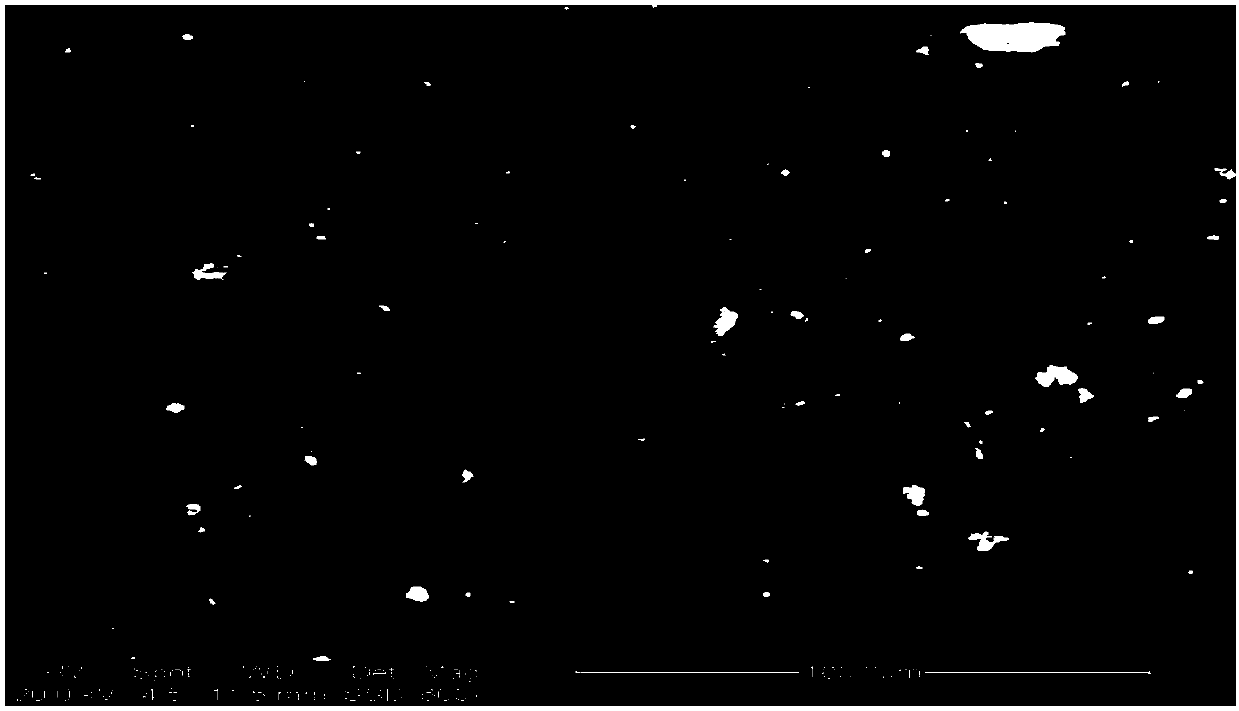

Image

Examples

Embodiment 1

[0023] A porous light carbon-based biological carrier, which is prepared according to the following steps:

[0024] 1) First, dissolve 15g of polyvinyl alcohol with a degree of polymerization of 1750 in 85ml of boiling water at 100°C and stir for 8 hours under reflux to obtain a 15% by weight polyvinyl alcohol solution;

[0025] 2) Next, take coke powder with a particle size of 300 mesh and put it in a nitric acid solution with a concentration of 50% by weight at room temperature for oxidation modification, treat it for 2 hours, take it out and wash it to neutral, and then wash it with tap water for 3 times;

[0026] 3) Then dry the coke powder in an oven at a constant temperature of 100°C for 2 hours;

[0027] 4), then add 5g of coke powder, 5ml of sodium lauryl sulfate aqueous solution with a concentration of 0.5% by weight and 2ml of an aqueous solution of glutaraldehyde with a concentration of 0.5% by weight to the 100ml of polyvinyl alcohol solution in step 1) Stir rapid...

Embodiment 2

[0033] A porous light carbon-based biological carrier, which is prepared according to the following steps:

[0034] 1) First, dissolve 10g of polyvinyl alcohol with a degree of polymerization of 1850 in 90ml of boiling water at 100°C and stir for 8 hours under reflux to obtain a 10% by weight polyvinyl alcohol solution;

[0035] 2) Next, take coke powder with a particle size of 180 mesh and put it in a nitric acid solution with a concentration of 30% by weight at room temperature for oxidative modification, treat it for 3 hours, take it out and wash it to neutral, and then wash it with tap water 4 times;

[0036] 3) Then dry the coke powder in an oven at a constant temperature of 90°C for 1.5h;

[0037] 4) Add 10g of coke powder, 5ml of sodium lauryl sulfate aqueous solution with a concentration of 1.0% by weight and 2ml of an aqueous solution of glutaraldehyde with a concentration of 1.0% by weight to the 100ml of polyvinyl alcohol solution in step 1) Stir rapidly for 3 hour...

Embodiment 3

[0043] A porous light carbon-based biological carrier, which is prepared according to the following steps:

[0044] 1) First, dissolve 5g of polyvinyl alcohol with a degree of polymerization of 1900 in 95ml of boiling water at 100°C and stir for 8 hours under reflux to obtain a 5% by weight polyvinyl alcohol solution;

[0045] 2) Next, take coke powder with a particle size of 200 mesh and put it in a nitric acid solution with a concentration of 10% by weight at room temperature for oxidation modification, treat it for 5 hours, take it out and wash it to neutral, and then wash it with tap water for 3 times;

[0046] 3), and then dry the coke powder in an oven at a constant temperature of 90°C for 2 hours;

[0047] 4), then add 5g of coke powder, 5ml of sodium lauryl sulfate aqueous solution with a concentration of 2.0% by weight and 2ml of an aqueous solution of glutaraldehyde with a concentration of 1.5% by weight to the 100ml of polyvinyl alcohol solution in step 1) Stir rap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com