High-performance adhesive for shoemaking

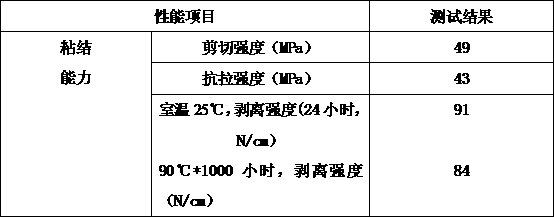

A high-performance, adhesive technology, used in adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of poor storage stability, poor water resistance, poor heat resistance, etc., and achieve low cost and environmental protection. The effect of good resistance and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] A high-performance adhesive for shoemaking, made of the following raw materials in parts by weight: 120 parts of styrene, 135 parts of ethyl acetate, 25 parts of neoprene CR121, 16 parts of xylene, 4,4'-diphenyl 1.6 parts of methyl methane diisocyanate, 10 parts of polyisobutylene, 2 parts of 3-aminopropyltrimethoxysilane, 2.5 parts of polytetrahydrofuran ether glycol, 4 parts of SG-2 type PVC resin, 1.8 parts of ferrocene, chlorohydrin rubber 8 parts of H45, 6 parts of epoxy resin modified polyamide hot melt adhesive, 3 parts of zinc oxide, 18 parts of nano wollastonite powder, 1.5 parts of antioxidant RD, 2 parts of 2-mercaptobenzimidazole, 3 parts of stearic acid 1.5 parts of accelerator DM, 1.5 parts of accelerator TMTD, 6 parts of glycerol triglyceride, 1 part of N-(β-aminoethyl)-γ-aminopropyltrimethyl(ethyl)oxysilane, over Dicumyl oxide 2 parts, silane coupling agent KH550 1.8 parts, antioxidant DLTP 1.5 parts, carbon black N339 15 parts, N660 carbon black 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com