Method for processing natural dried daylily

A processing method and technology of day lily, which is applied in application, food preparation, climate change adaptation, etc., can solve the problems of light weight, lower quality of dried day lily, and lack of attention to methods, so as to prevent compression deformation or heat generation, and avoid discoloration and loss of nutrients, avoiding the effects of injury and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] On June 10, 2012, day lily was picked in Baizhuang Village, Longchi Town, Xiushan County. The color of the yellow flower buds was yellow, and the flower mouth was about to split. The picking started at 5:00 in the morning and stopped when the dew dried up at 9:40. Harvest; when picking, hold the flower stalk with your thumb and forefinger, fold it lightly from the connection between the flower stalk and the moss stalk, and place each flower directly in a bamboo basket with a depth of 30cm.

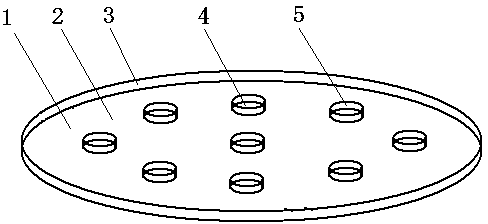

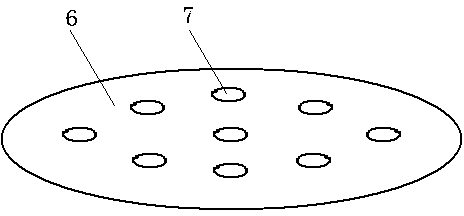

[0021] Then put the picked fresh daylily into the special bamboo sieve tray for daylily processing, and spread it fluffy, then put the bamboo sieve tray into the steaming rack in the steaming room, and fill the large pot under the steaming rack with water , then close the door of the steaming room, start a fire in the stove outside the door, and generate steam after the water in the pot is heated, stop the fire when the temperature in the steaming room reaches 80°C, and keep it for a...

Embodiment 2

[0023] On June 15, 2012, daylilies were picked in Jianguo Village, Longchi Town, Xiushan County. On that day, the yellow flower buds turned yellow, and the flower mouth was about to split. Picking started at 5:00 in the morning, and stopped picking at 9:45 when the dew dried up. Harvesting; when picking, hold the flower stalk with your thumb and forefinger, gently fold it from the connection between the flower stalk and the moss stalk, and put it flat in the bamboo basket after each picking. The depth of the bamboo basket is 35cm.

[0024] Then put the picked fresh daylily into the special bamboo sieve tray for daylily processing, and spread it fluffy, then put the bamboo sieve tray into the steaming rack in the steaming room, and fill the large pot under the steaming rack with water , then close the door of the steaming room, start a fire in the stove outside the door, and generate steam after the water in the pot is heated, stop the fire when the temperature in the steaming r...

Embodiment 3

[0026] On July 10, 2012, day lily was picked in Taiping Village, Qingxichang Town, Xiushan County. The color of the yellow flower buds was yellow, and the flower mouth was about to split. Picking started at 5:00 in the morning and stopped when the dew dried up at 9:10. Harvesting; when picking, hold the flower stalk with your thumb and forefinger, gently fold it from the connection between the flower stalk and the moss stalk, and place each flower directly in a bamboo basket with a depth of 45cm.

[0027] Then put the picked fresh daylily into the special bamboo sieve tray for daylily processing, and spread it fluffy, then put the bamboo sieve tray into the steaming rack in the steaming room, and fill the large pot under the steaming rack with water , then close the door of the steaming room, start a fire in the stove outside the door, and generate steam after the water in the pot is heated, stop the fire when the temperature in the steaming room reaches 90°C, and keep it for a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com