Temperature-sensitive self-cleaning polyvinylidene fluoride film and preparation method thereof

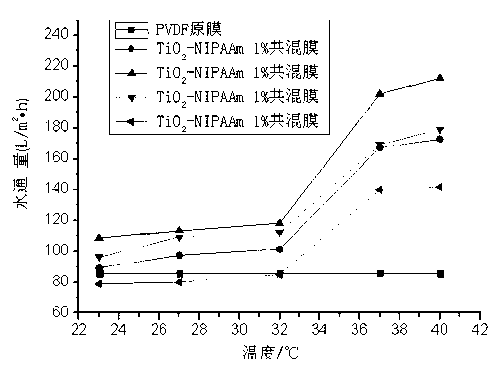

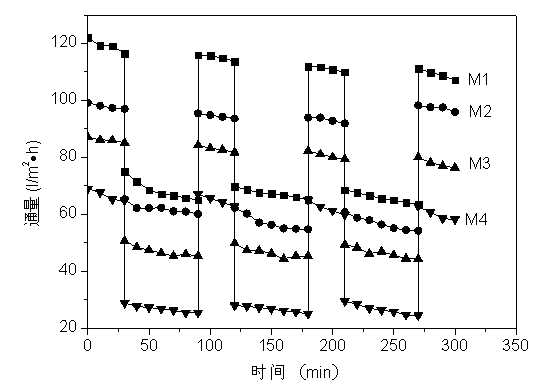

A technology of polyvinylidene fluoride film and polyvinylidene fluoride, which is applied in the field of temperature-sensitive self-cleaning polyvinylidene fluoride film and its preparation, can solve the problems of limited practical application of titanium dioxide modified film and responsive film, poor control effect, Low anti-biological pollution performance and other problems, to achieve good self-cleaning anti-pollution performance, easy operation, good self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the temperature-sensitive self-cleaning polyvinylidene fluoride membrane of the present invention comprises the following processes:

[0025] (1) Preparation of titanium dioxide / silane coupling agent MPS (γ-(methacryloyloxy)propyltrimethoxysilane) nanoparticles Add the silane coupling agent MPS, deionized water and ammonia water to the ethanol dispersion solution of titanium dioxide In the process, white titanium dioxide / silane coupling agent MPS nanoparticles were obtained by pulverization after ultrasonication, mechanical stirring, centrifugation and vacuum drying.

[0026] (2) Preparation of titanium dioxide / N-isopropylacrylamide nanoparticles

[0027] Add titanium dioxide / silane coupling agent MPS nanoparticles and initiator into a 100ml three-necked flask that has been added with ethanol, stir and react at 70-75°C under nitrogen protection for 24-48 hours, centrifuge and vacuum dry, pulverize and disperse , to obtain white titanium dioxid...

Embodiment 1

[0032] 1) Preparation of titanium dioxide / silane coupling agent MPS nanoparticles

[0033] Add 0.62g of silane coupling agent MPS, 1.3ml of deionized water and 0.68g of ammonia water (25wt%) into 25ml of ethanol titanium dioxide dispersion solution containing 1g of titanium dioxide ultrasonically for 0.5h, then ultrasonically for 1h, mechanically stirred (500rpm, 48h , room temperature), centrifugation and vacuum drying to obtain white titanium dioxide / silane coupling agent MPS nanoparticles.

[0034] 2) Preparation of titanium dioxide / N-isopropylacrylamide nanoparticles

[0035] Add 0.15g of titanium dioxide / silane coupling agent MPS nanoparticles and 0.3g of azobisisobutylcyanide into a 100ml three-neck flask to which 5ml of ethanol has been added, stir and react at 75°C under nitrogen protection for 24 hours, and centrifuge Vacuum-dried, pulverized and dispersed to obtain white titanium dioxide / N-isopropylacrylamide nanoparticles.

[0036] 3) Preparation of temperature-se...

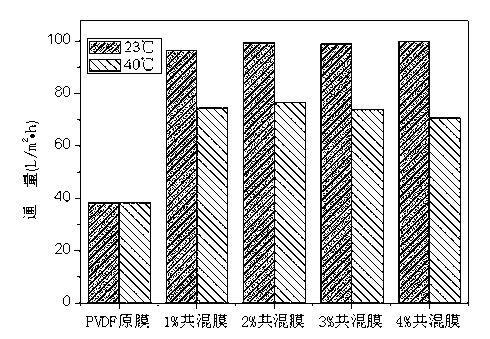

Embodiment 2

[0040] 1) Preparation of titanium dioxide / silane coupling agent MPS nanoparticles: same as Step 1 of Example 1.

[0041] 2) Preparation of titanium dioxide / N-isopropylacrylamide nanoparticles: same as Step 2 of Example 1.

[0042] 3) Preparation of temperature-sensitive self-cleaning polyvinylidene fluoride membrane

[0043] Add 2 g of polyvinylidene fluoride powder, 0.2857 g of titanium dioxide / N-isopropylacrylamide nanoparticles and 0.2 g of pore-forming agent PVP into a round-bottomed flask containing 12 ml of dimethylacetamide to form a titanium dioxide / N- The blended film with the mass fraction of isopropylacrylamide nanoparticles being 2% was stirred evenly at 70°C for 48 hours; the solution was cooled, defoamed, and the film was scraped, and the coagulation bath was composed of deionized water at a temperature of 20°C; Titanium dioxide / N-isopropylacrylamide nanoparticles / polyvinylidene fluoride blend film was obtained after washing with ion water and natural drying.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com