Graphene elastomer nano composite material with high dielectric constant and low dielectric loss and preparation method thereof

A nanocomposite material and graphene technology, which is applied in the field of graphene elastomer nanocomposite materials and its preparation, can solve the problems of high filling amount and performance degradation of composite materials, and achieve the effect of improving dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Dissolve 8 mg of graphite oxide synthesized by the Hummers method in 40 ml of deionized water, and disperse with 300 W ultrasonic for 1 hour. The graphite oxide is stripped into graphene oxide, and a stable suspended graphene oxide aqueous solution is obtained;

[0024] (2) the graphene oxide aqueous solution prepared by step (1) and 10g of nitrile rubber emulsion (the brand produced by Zeom company is the nitrile rubber emulsion of Nipol1571H, wherein the solid content of nitrile rubber is 40wt%, in nitrile rubber The monomer acrylonitrile content is 37wt%) and mix evenly, then add 0.02g of dicumyl peroxide and 0.02g of triallyl isocyanurate to dissolve and disperse completely;

[0025] (3) Use a vacuum rotary evaporator to evaporate most of the water from the mixed emulsion obtained in step (2) at 45°C, then dry and dehydrate at 45°C, and obtain a preformed composite membrane after all the water is evaporated;

[0026] (4) The obtained preformed composite membrane...

Embodiment 2

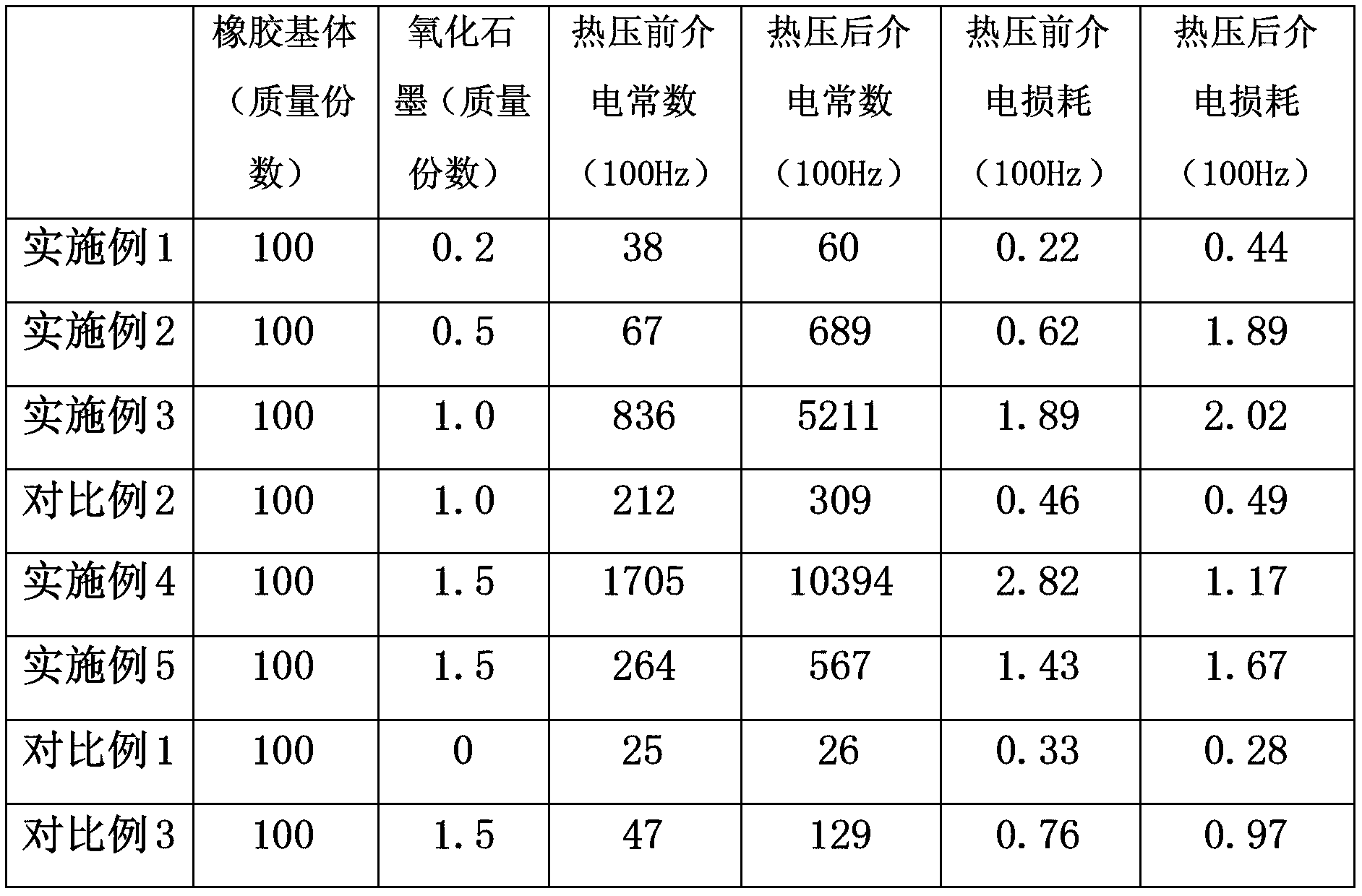

[0030] The preparation method is the same as that in Example 1, except that the amount of graphite oxide used in step (1) is 20 mg dispersed in 100 ml of water. The test results are shown in Table 1.

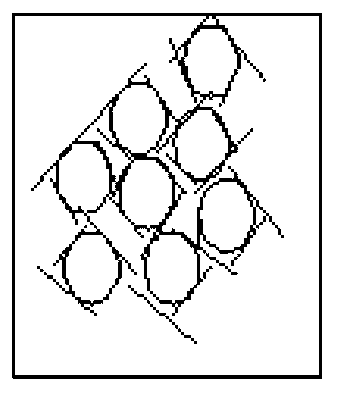

[0031] Obtaining the graphene elastomer nanocomposite composition is the nitrile rubber of 4g, the graphene of 20mg; Particle network structure.

Embodiment 3

[0033] The preparation method is the same as that in Example 1, except that the amount of graphite oxide used in step (1) is 40 mg dispersed in 200 ml of water. The test results are shown in Table 1.

[0034] Obtaining the graphene elastomer nanocomposite composition is the nitrile rubber of 4g, the graphene of 40mg; The structure of this composite material is that the graphene sheet is dispersed in the nitrile rubber at the nanometer level, and forms the graphene sheet to wrap the latex particle network structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com