Selection-smelting combined technology for treating mixed ore containing molybdenum, oxygen, sulfur and copper

A technology of dressing and smelting combined and mixed ore, which is applied to the improvement of process efficiency, flotation, solid separation, etc., can solve the problems of high production cost, low recovery rate of sulfidation flotation, and interference of ore slime, so as to reduce production cost, The effect of improving resource utilization and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, the mixed ore containing molybdenum, oxygen and sulfur from Yulong in Qamdo, Tibet is used. The valuable minerals are chalcopyrite, malachite, and molybdenite; the gangue minerals are mainly quartz and clay minerals. The ore contains 1.51wt% copper and 0.025wt% molybdenum, and the copper in the copper oxide accounts for 30wt% of the total copper.

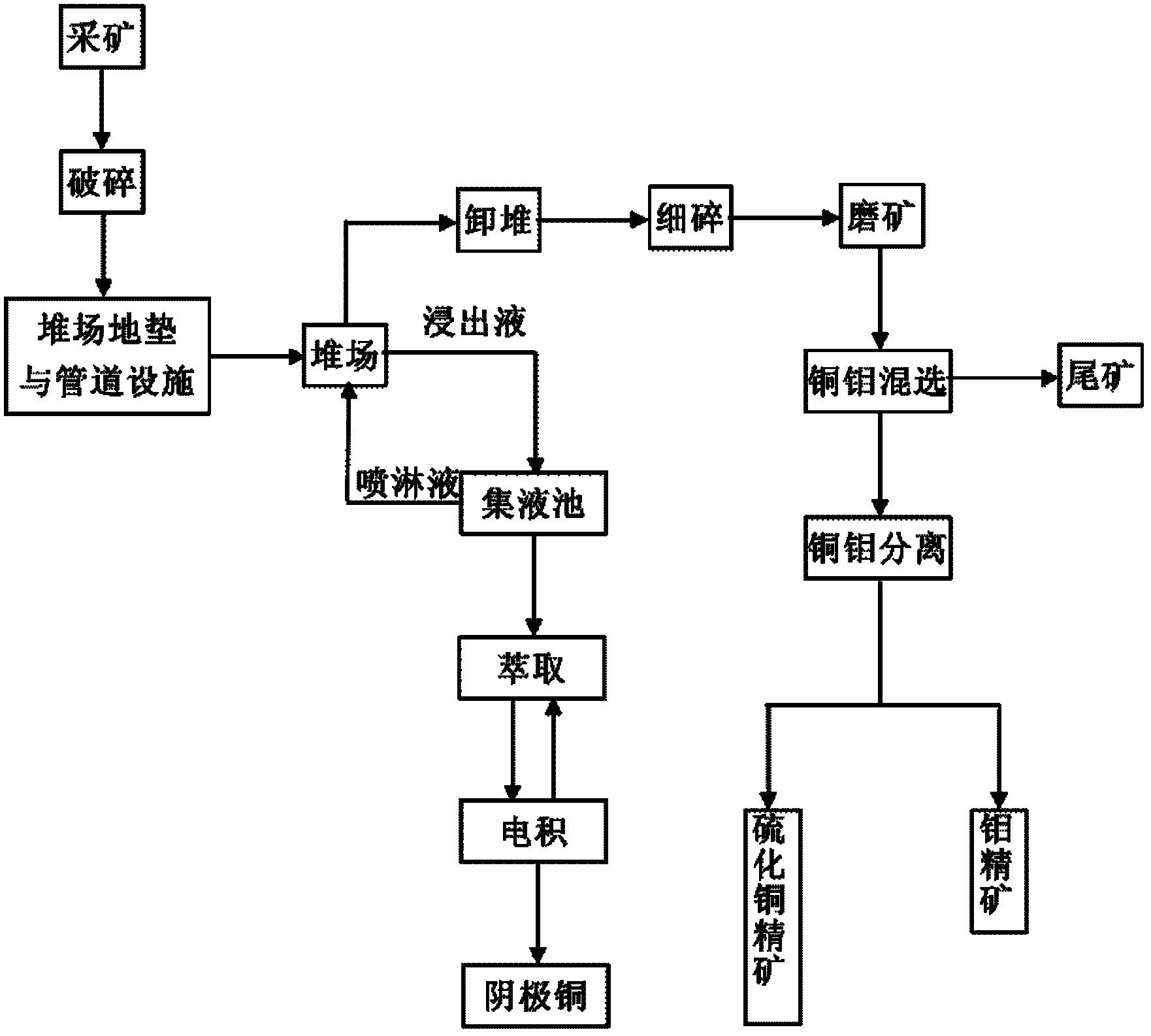

[0024] Such as figure 1 As shown in the process flow chart, using the method of the present invention, the raw ore is crushed to a particle size of 25mm or less, the pile height is 4.5m, the spraying dilute sulfuric acid concentration is 1.5mol / L, and the spraying intensity is 7.5L / (h.m 2 ), the leachate flows to the sump for cyclic spraying, and the heap is unloaded after 1.5 months of leaching. When the copper ion concentration of the leaching solution is greater than 1g / L, the copper is extracted with a mixture of organic phase extractant Lix64N and kerosene to transfer the low concentration of copper int...

Embodiment 2

[0028] The mixed ores containing molybdenum, oxygen and sulfur from Yulong in Qamdo, Tibet are used. The valuable minerals are chalcopyrite, malachite, molybdenite, and a small amount of chalcocite. The gangue minerals are mainly quartz and clay minerals. The ore contains 1.48wt% copper, 0.023wt% molybdenum, and copper in copper oxide accounts for 29wt% of the total copper.

[0029] Such as figure 1 As shown in the process flow chart, using the method of the present invention, the raw ore is crushed to a particle size of less than 30mm, the pile height is 5m, the spraying dilute sulfuric acid concentration is 1.8mol / L, and the spraying intensity is 8.5L / (h.m 2 ), the leaching liquid flows to the sump for circulating spraying. When the leaching liquid reaches a copper ion concentration of more than 1g / L, the organic phase extractant Lix64N and kerosene are used to extract copper, so that the very low copper concentration is transferred to the organic phase , Then use sulfuric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com