Silk-fibroin-based antibacterial nanofiber and preparation method thereof

A silk fibroin and nanofiber technology, applied in the field of medical materials, can solve problems such as poor mechanical properties of materials, and achieve the effects of good application prospects, lasting antibacterial effect, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

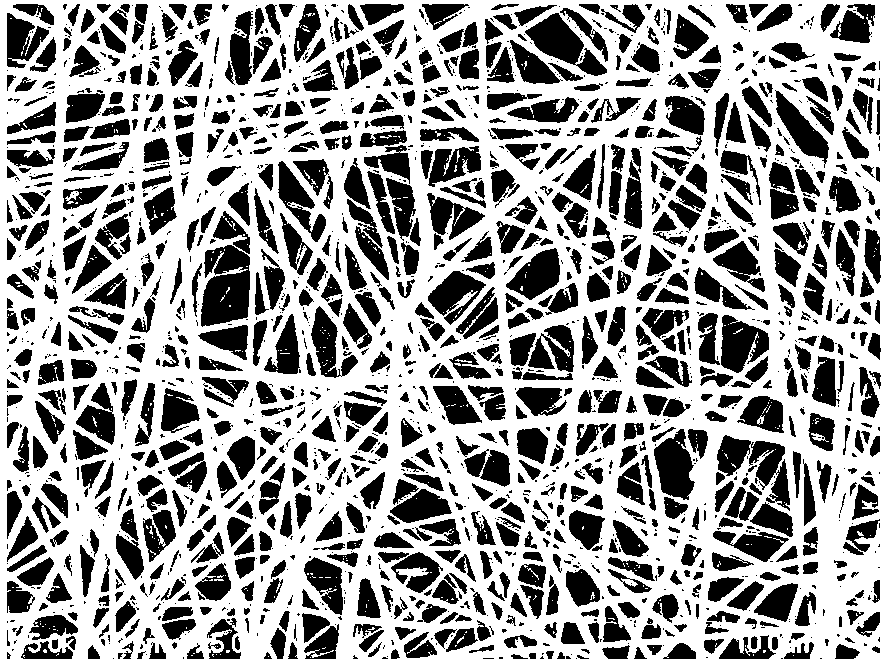

Image

Examples

Embodiment 1

[0030] A kind of silk fibroin-based antibacterial nanofiber, its preparation method comprises the steps:

[0031] (1) Natural mulberry silk was degummed by boiling 0.05% sodium carbonate solution for 30 minutes, and obtained pure silk fibroin fiber after repeating 3 times; the silk fibroin was dissolved in LiBr:C 2 h 5 OH:H 2 O=45:44:11 (mass ratio) mixed solution, stirred and dissolved in a 70°C water bath to obtain a regenerated silk fibroin solution; after dialysis, filtration, and film formation, a regenerated silk fibroin film is formed;

[0032] (2) Prepare the regenerated silk fibroin film, titanium dioxide and chitosan in a mass ratio of 95:3:2, first dissolve the regenerated silk fibroin film and titanium dioxide in formic acid, and then add chitosan to the above solution , stirred at room temperature for 4h, and prepared into a spinning solution with a mass fraction of 10%;

[0033] (3) Spinning the above-prepared spinning solution at room temperature using an ele...

Embodiment 2

[0036] A kind of silk fibroin-based antibacterial nanofiber, its preparation method comprises the steps:

[0037] (1) Natural mulberry silk was degummed by boiling with 0.05% sodium carbonate solution for 30 minutes, and obtained pure mulberry silk fibroin fiber after repeated 3 times; the silk fibroin was dissolved in CaCl 2 :C 2 h 5 OH: H2 O=1:2:8 (molar ratio) mixed solution, stirring and dissolving in a 70°C water bath to obtain a regenerated silk fibroin solution; after dialysis, filtration, and film formation, a regenerated silk fibroin film is formed;

[0038] (2) Prepare the regenerated silk fibroin film, titanium dioxide and chitosan in a mass ratio of 70:15:15, first dissolve the regenerated silk fibroin film and titanium dioxide in formic acid, and then add chitosan to the above solution , stirred at room temperature for 6h, and prepared into a spinning solution with a mass fraction of 20%;

[0039] (3) Spinning the above-mentioned spinning solution at room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com