Side packaging structure of electronic module

A packaging structure and electronic module technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of low adhesion, inapplicability, and poor fluidity of substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

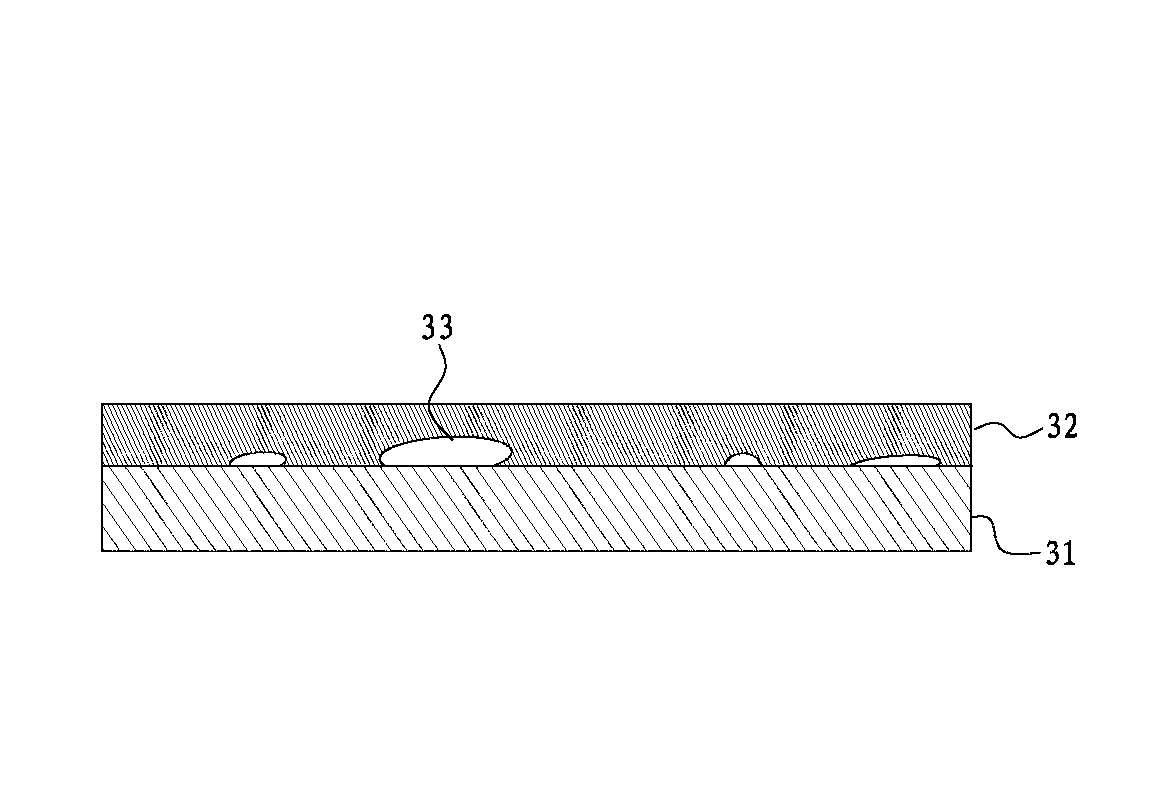

[0039] Silicone (silicone) has the characteristics of the two known packaging frame adhesive materials. It can use silicone oil to adjust the viscosity, and can use printing and coating methods to spread the glue, and can be polymerized at low temperature to make the seal The material inside the frame is less susceptible to temperature. At the same time, silica gel is an ultra-low polar material, which cannot be affected by general polar solvents and plasticizers, so water vapor is not easy to enter the sealing frame due to adsorption, wetting, and diffusion. Therefore, the present invention utilizes silica gel as the main material of the sealing frame, so as to have the advantages of the conventional two sealing frame adhesive materials.

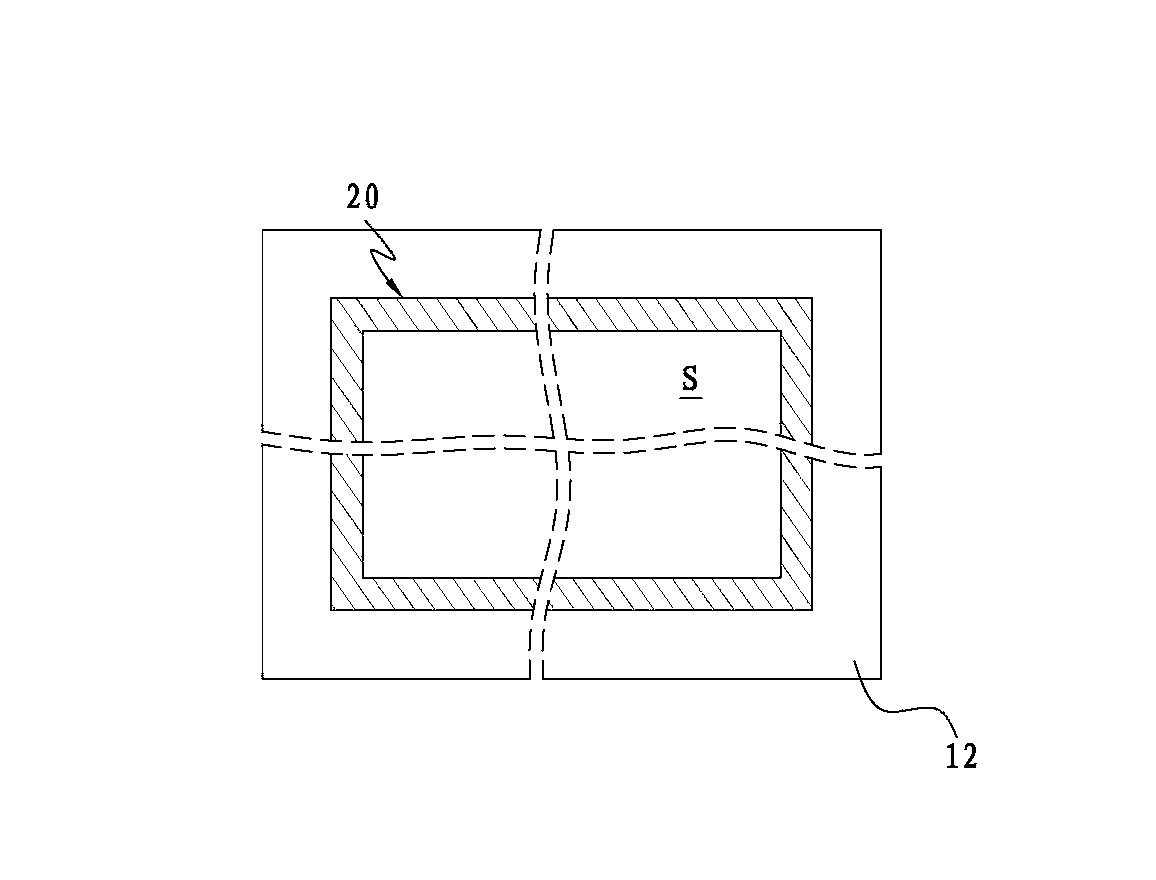

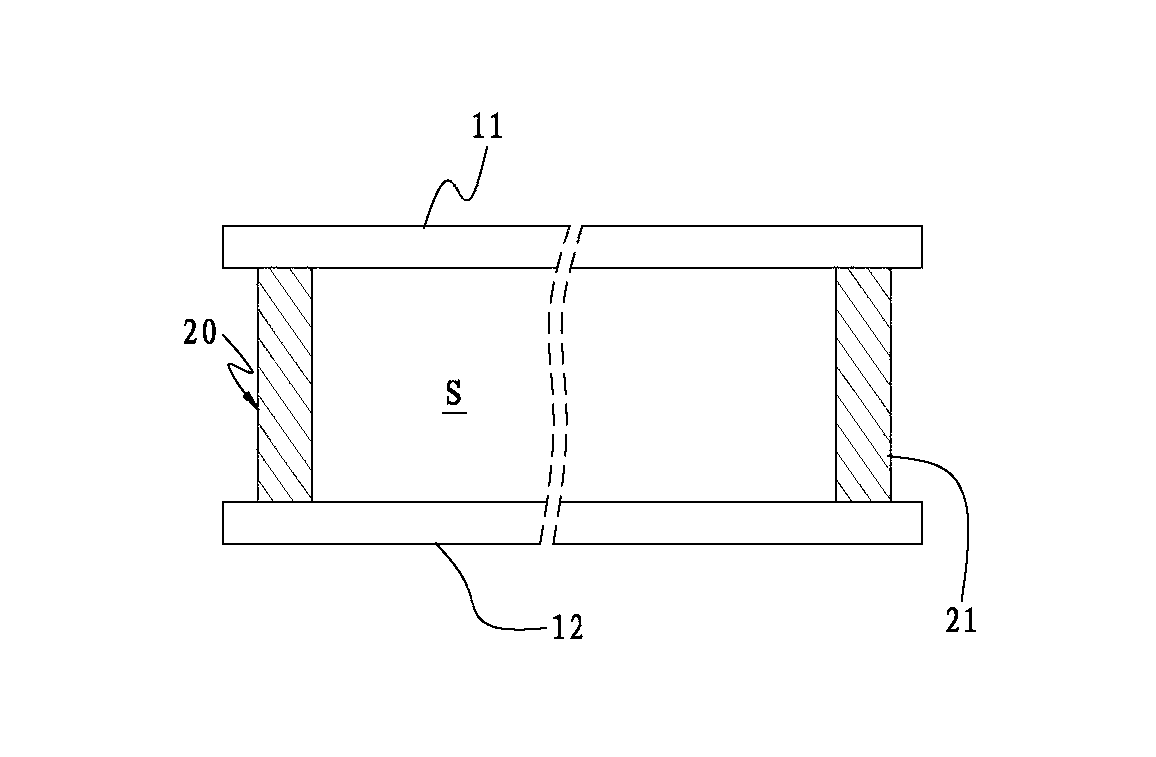

[0040] Please refer to Figure 1A , Figure 1B As shown, it is a sche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com