Copolymer containing lysine residue on side chain and preparation method thereof as well as fibrinolytic functional material

A technology of lysine residue and fibrinolysis function, which is applied in the directions of single-component synthetic polymer rayon, transportation and packaging, rayon manufacturing, etc. The effect of control, simple operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] 2. Preparation of copolymers containing lysine residues in their side chains

[0034] The lysine functional monomer is placed in a solution containing an initiator and a vinyl monomer to react, the reaction temperature is 60-80°C, and the reaction time is 2-6 hours; the initiator and the lysine functional monomer and vinyl The molar ratio of the base monomer is 1:100~1:400.

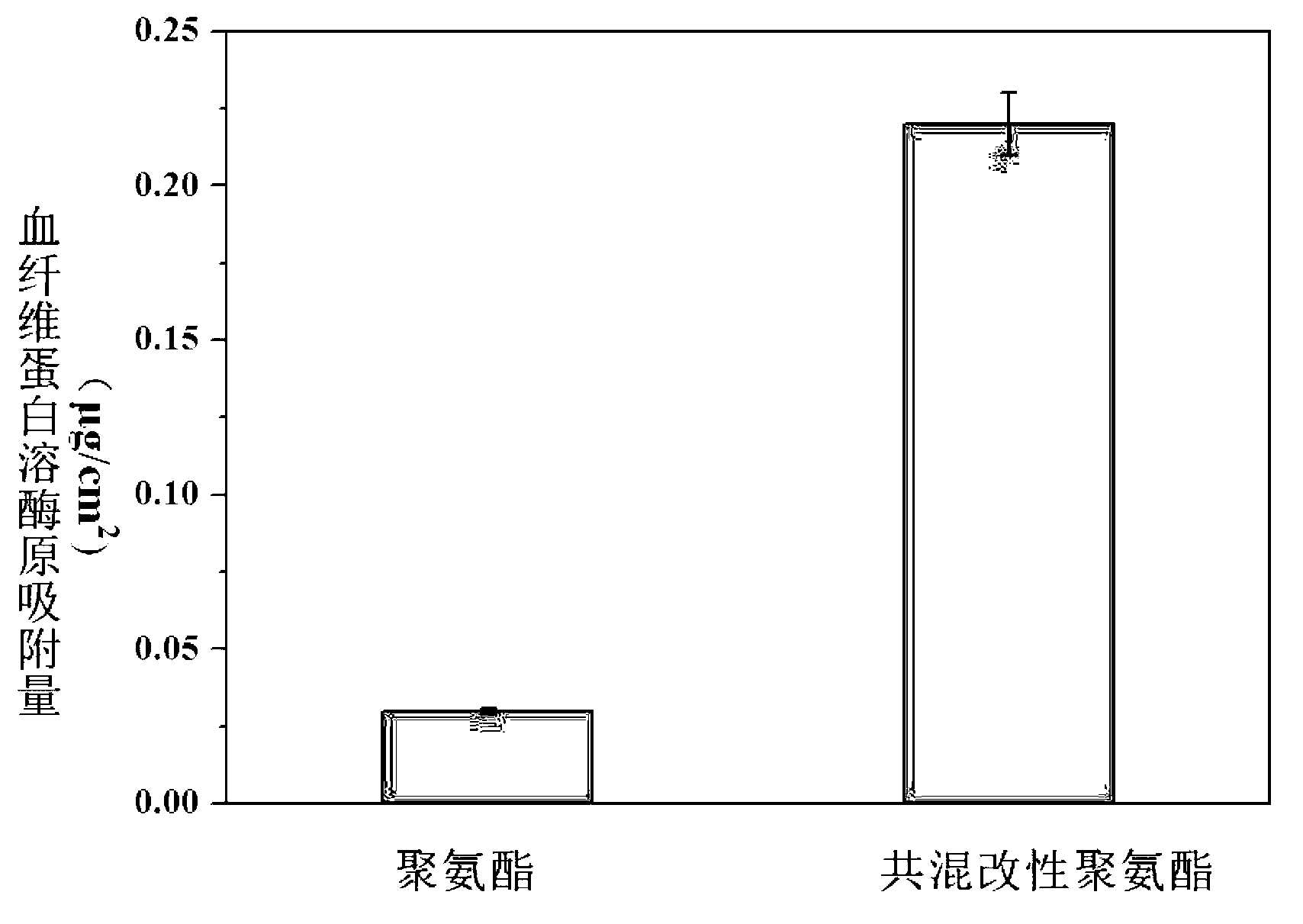

[0035] On the basis of the above, the preparation of fibrinolytic functional materials is carried out:

[0036] The copolymer containing lysine residues in the side chain and the commercially available medical polymer raw materials are physically blended according to a certain mass ratio and subjected to corresponding molding processing to obtain a material with a fibrinolytic function.

[0037] The ε-amino and carboxyl protected lysine described in this technical scheme is ε-amino and carboxyl protected lysine; the described lysine solution is ε-amino and carboxyl protected The dichloromethane o...

Embodiment 1

[0039] Example 1: Preparation of Fibrinolytic Active Polylactic Acid Membrane

[0040] (1) Preparation of lysine functional monomer

[0041]Put 1.36g of lysine hydrochloride whose ε-amino and carboxyl groups are protected by tert-butoxycarbonyl, 0.82g of triethylamine, and 40mL of dry dichloromethane in a 100mL reaction flask, and stir to dissolve. Slowly drop 0.42 mL of methacryloyl chloride into the reaction flask, stir the reaction at room temperature for 6 hours, remove the precipitate by filtration, and remove the solvent by rotary evaporation of the filtrate in vacuo to obtain an intermediate. The intermediate was placed in 20 mL of 28% 1,4-dioxane solution, stirred and reacted at room temperature for 8 hours, and the solvent was removed by vacuum rotary evaporation to obtain lysine functional monomer.

[0042] (2) Preparation of polymethacrylate-(2-hydroxy)ethyl ester copolymer

[0043] Put 0.3g of lysine functional monomer, 3.0g of (2-hydroxy)ethyl methacrylate, 0.02...

Embodiment 2

[0046] Embodiment 2: Preparation of fibrinolytically active polylactic acid nanofibers

[0047] (1) Preparation of lysine functional monomer

[0048] Put 1.36g of lysine hydrochloride whose ε-amino and carboxyl groups are protected by tert-butoxycarbonyl, 0.82g of triethylamine, and 40mL of dry dichloromethane in a 100mL reaction flask, and stir to dissolve. Slowly drop 0.42 mL of methacryloyl chloride into the reaction flask, stir the reaction at room temperature for 6 hours, remove the precipitate by filtration, and remove the solvent by rotary evaporation of the filtrate in vacuo to obtain an intermediate. The intermediate was placed in 20 mL of 28% 1,4-dioxane solution, stirred and reacted at room temperature for 8 hours, and the solvent was removed by vacuum rotary evaporation to obtain lysine functional monomer.

[0049] (2) Preparation of polymethacrylate-(2-hydroxy)ethyl ester copolymer

[0050] Put 0.3g of lysine functional monomer, 3.0g of (2-hydroxy)ethyl methacry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com