Ester exchange catalysis method

A catalyst and dimethyl ester technology are applied in the field of catalyzing the transesterification of phenol and dimethyl ester to produce diphenyl ester, which can solve the problems of complex production process, harmful emissions, etc. The effect of high ester yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

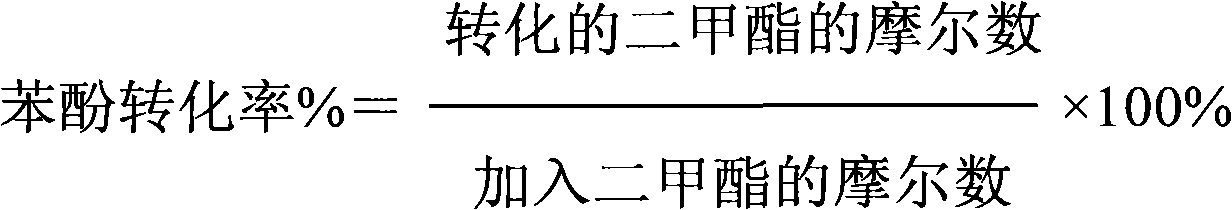

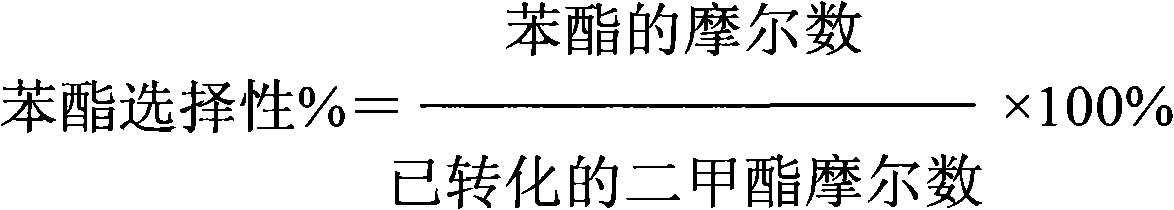

[0033] Phenol, dimethyl carbonate, solvent and catalyst (the mol ratio of zinc nitrate and titanium silicon molecular sieve 0.2: 1) is 200: 1 according to solvent methanol and catalyst mass ratio, and the mass ratio of phenol and dimethyl carbonate and catalyst is 20 : 20: 1, the reaction was carried out at a temperature of 200° C. and a pressure of 1.5 MPa. The results of the reaction for 2 hours were as follows: the conversion rate of dimethyl carbonate was 47%; the selectivity of methyl phenyl carbonate was 78%.

Embodiment 2

[0035] With phenol, dimethyl carbonate, solvent and catalyzer (the mol ratio 1: 1 of zinc phosphate and titanium silicon molecular sieve) is 100: 1 according to the mass ratio of solvent methanol and catalyzer, the mass ratio of phenol and dimethyl carbonate and catalyzer is 40:20:1, the reaction was carried out at a temperature of 150°C and a pressure of 1.0 MPa. The results of the reaction for 2 hours were as follows: the conversion rate of dimethyl carbonate was 38%; the selectivity of methyl phenyl carbonate was 86%.

Embodiment 3

[0037]With phenol, dimethyl carbonate, solvent and catalyzer (the mol ratio 0.1: 1 of zinc sulfate and titanium silicon molecular sieve) is 500: 1 according to the mass ratio of solvent acetone and catalyzer, the mass ratio of phenol and dimethyl carbonate and catalyzer is 80:20:9, the reaction was carried out at a temperature of 160°C and a pressure of 0.1 MPa. The results of the reaction for 2 hours were as follows: the conversion rate of dimethyl carbonate was 53%; the selectivity of methyl phenyl carbonate was 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com