Micrometer wire made from perylene bisimide derivatives and application of micrometer wire

A perylene imide and derivative technology, applied in the field of efficient and fast detection of hydrazine hydrate atmosphere, can solve the problems of unfavorable miniaturization development, low sensitivity of gas sensitivity, and limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The preparation method of described perylene imide derivatives:

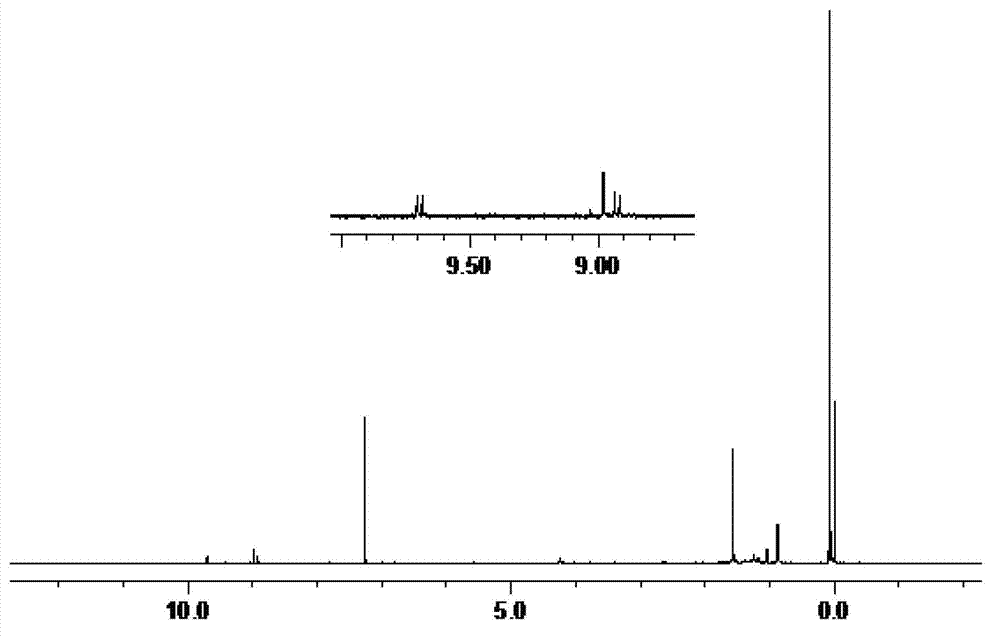

[0015] 1) N, N' - Dissolve bis(3,7-dimethyloctyl)perylene-1,7-dibromo-3,4:9,10-perylenediimide (0.50 g, 0.6 mmol) with 0.81 g cuprous hydride 25mL N, N' -Dimethylformamide, stirred at 150 oC for 6 hours under nitrogen protection, then added 150 mL of water, stirred overnight, filtered with suction, dried, and separated on a silica gel column (eluent: chloroform) to obtain 0.35 g N, N' -Bis(3,7-dimethyloctyl)perylene-1,7-dicyano-3,4:9,10-perylenediimide (PTCDI-CN 2 C 10 ), the yield was 81.2%. 1 H NMR (CDCl 3 ): δ 9.70 (d, J = 8.0 Hz, 2H), 8.98 (s, 2H), 8.94 (d, J = 8.0 Hz, 2H), 4.27 (t, J =10.8 Hz, 4H), 1.56-0.86 (m, 38H). MALDI-MS: 720.9 (calcd.721.9). Anal. Calcd for C 46 h 48 N 4 o 4 : C, 76.64; H, 6.71; N, 7.77; Found: C, 75.85; H, 6.72; N, 8.12.

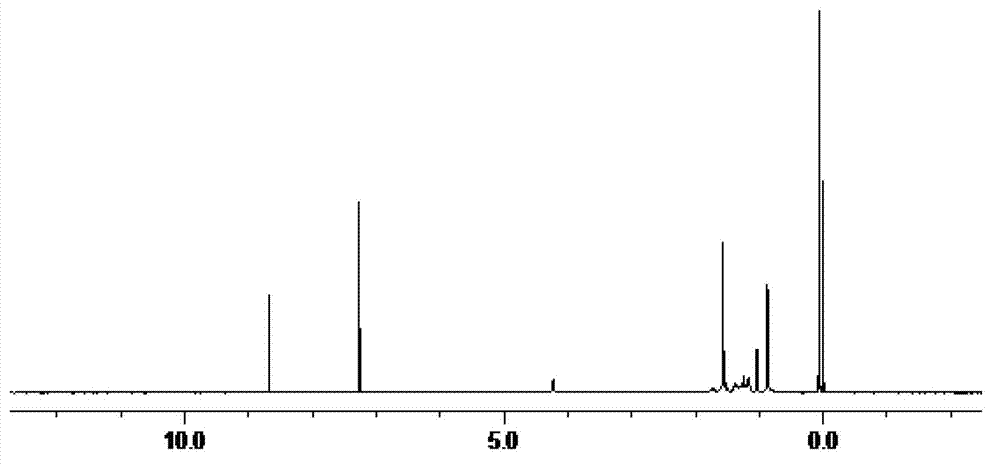

[0016] 2) 1,6,7,10-tetrachloro-3,4,9,10-perylenetetracarboxylic dianhydride (0.60 g, 1.14 mmol) was dissolved in 25 mL with 2.0 g pot...

Embodiment 2

[0018] Preparation method of micro- and nanowires based on the above-mentioned peryleneimide derivatives:

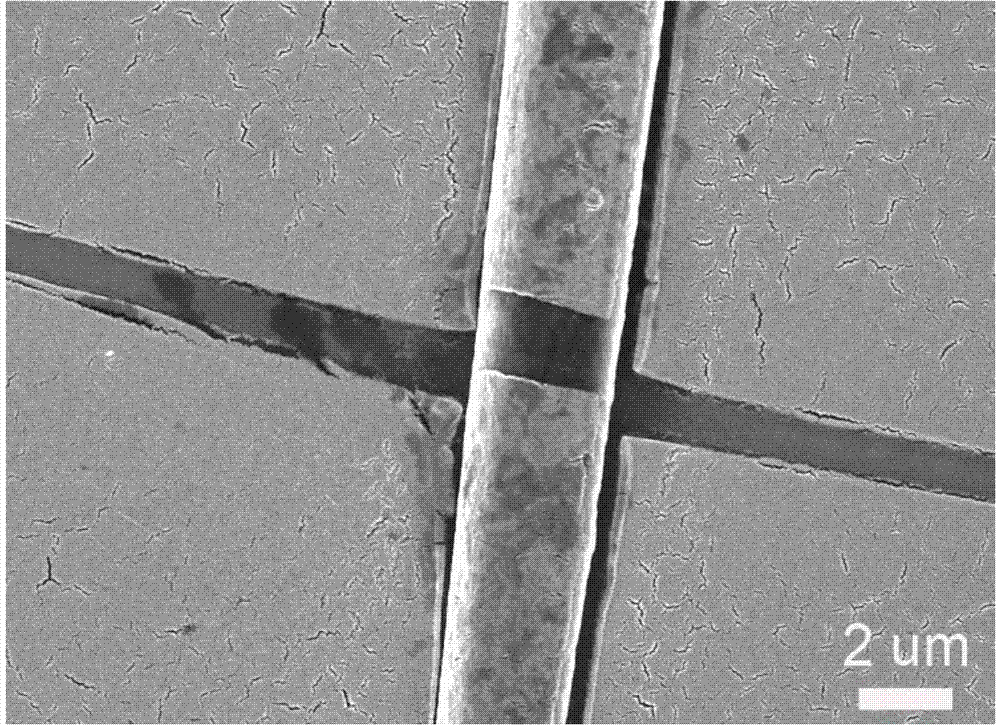

[0019] 1) Add 0.3 mL of PTCDI-CN 2 C 10 Chloroform solution (1 mg.mL -1 ) into a weighing bottle with a capacity of 10 mL, then add 0.9 mL of chloroform and 1.8 mL of methanol, shake for 10 minutes and let stand for 24 hours to obtain a brownish-red precipitate, which is characterized by a scanning electron microscope as a micron line with a diameter of 0.4-2 μm .

[0020] 2) Add 0.4 mL PTCDI-Cl 4 C 10 Chloroform solution (1 mg.mL -1 ) into a weighing bottle with a capacity of 10 mL, then add 0.1 mL of chloroform and 3.0 mL of methanol, shake for 10 minutes and let it stand for 12 hours to obtain a brownish-red precipitate, which is characterized by a scanning electron microscope as a micron line with a diameter of 1-3 μm .

Embodiment 3

[0022] Applications of micro- and nanowires based on the above-mentioned peryleneimide derivatives:

[0023] 1) Put PTCDI-CN 2 C 10 The micron wires are dispersed in methanol, drop-coated on the silicon wafer deposited with silicon dioxide, and after the solvent is evaporated and dried in the air, the 2-3 μm micron wires are selected as a mask, and the micron wires of 5 × 10 -5 In the Torr vacuum system, a gold layer of about 50 nm was deposited at a rate of 0.5 ? / s, and then the mask was removed to obtain PTCDI-CN 2 C 10 The detection electrode of the gas sensor.

[0024] Put the finished detection electrode into a sealed vacuum metal chamber with a volume of about 2 L, and the system is directly connected to the vacuum pump, and when the pressure of the vacuum system drops to 10 -4 Pa, connect the electrode to the Keithley 4200-SCS electrical detection system, and record the PTCDI-CN of the vacuum system 2 C 10 resistance (R 0 ), followed by injecting 2 μL of hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com