Back membrane material of solar cell module

A technology for solar cells and back films, applied in electrical components, circuits, photovoltaic power generation, etc., can solve problems such as the decline of weather resistance, and achieve the effects of good moisture resistance and gas resistance, excellent weather resistance, and high mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

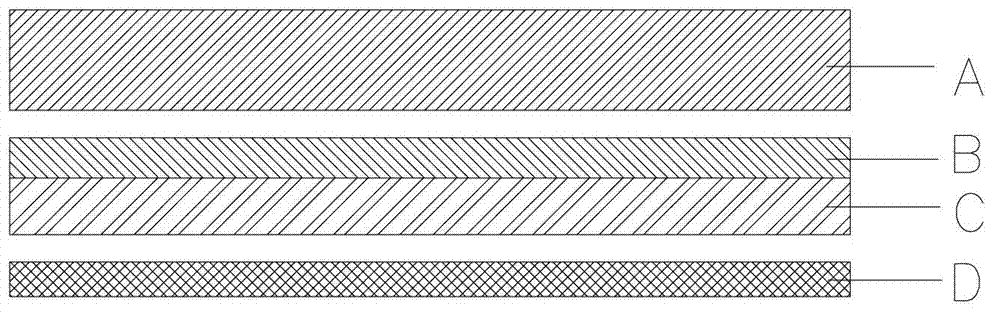

[0028] First, in terms of mass fraction, 5 parts of alkali-free glass fiber powder (Guangzhou Hetaisi Chemical Materials Co., Ltd.) and 1 part of polyethylene terephthalate (PET, Japan Polyplastics BN9015) pellets were added 1 part polyethylene glycol (PEG6000, Tianjin Tiantai Fine Chemicals Co., Ltd.), and mix evenly to form a PET mixture; the PET mixture and polylaurolactam (PA12, DuPont 159L, USA) are double-layered according to the ratio of 70:30 Co-extruded to obtain a 250-micron intermediate layer; then, dry-composite 25-micron-thick polyvinyl fluoride (PVF, DuPont, USA) on the PET surface Membrane, 400 μm thick ethylene-vinyl acetate copolymer (EVA, F806, Hangzhou First Photovoltaic Materials Co., Ltd.) was melt-coated on the surface of PA12.

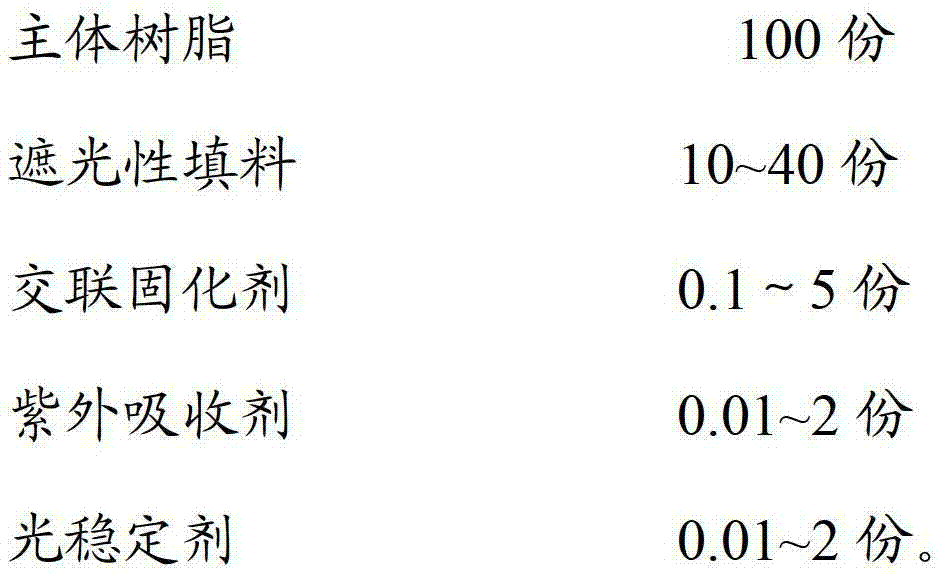

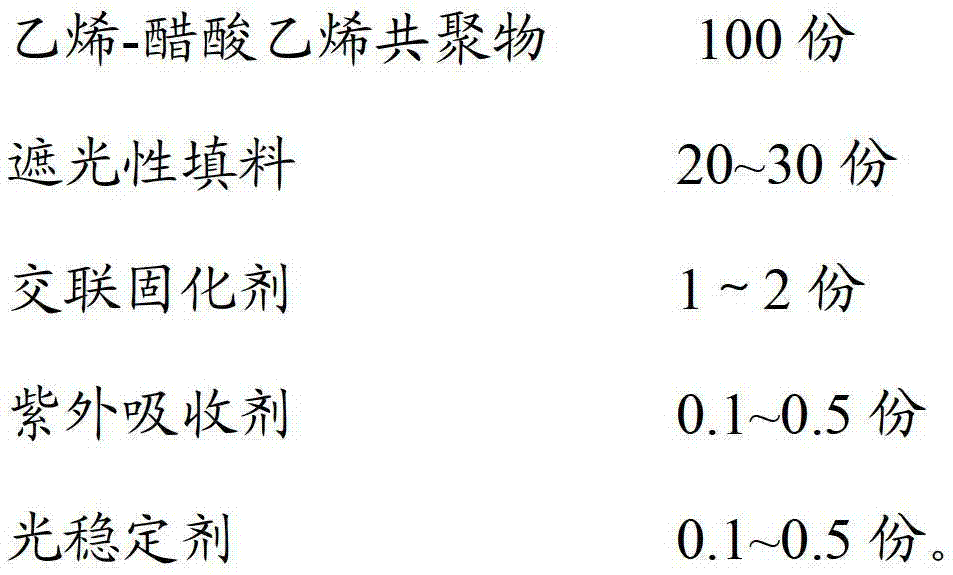

[0029] Among them, the EVA film is melted and extruded by adding crosslinking agent, ultraviolet absorber, light stabilizer and light-shielding filler to EVA resin. Specifically, in 100 parts of EVA resin (EVA250 from DuPont Com...

Embodiment 2

[0031] First, in terms of mass fraction, 10 parts of polybutylene terephthalate (PBT, Japan Toray Company 1494X02) pellets, 10 parts of alkali-free glass fiber powder (Hangzhou Gaoke Composite Materials Co., Ltd.) and 2 parts of polyethylene Diol (PEG8000, Jiangsu Haian Petrochemical Plant), and mixed evenly to form a PBT mixture; the PBT mixture and polysebacyl diamide (PA1010, DuPont 09-12, USA) were double-layered in a ratio of 65:35. Extruded to obtain a 280-micron intermediate layer; then, dry compound a 40-micron-thick polyvinylidene fluoride (PVDF, Arkema, France) film on the surface of PBT, and melt-coat a 350-micron-thick ethylene-vinyl acetate copolymer film on the surface of PA1010. Thin film (EVA, F806 of Hangzhou Foster Photovoltaic Materials Co., Ltd.).

[0032] Among them, the EVA film is melt-extruded by adding cross-linking agent, ultraviolet absorber, light stabilizer and light-shielding filler to EVA resin. Specifically, 100 parts of EVA (TPC Company of Sing...

Embodiment 3

[0034] First, in terms of mass fraction, 5 parts of alkali-free glass fiber powder (Guangzhou Bohao Composite Materials Co., Ltd.) and 1 part of polyethylene terephthalate (PET, Beijing Yanshan Petrochemical) pellets were added Diol (PEG6000, Tianjin Tiantai Fine Chemicals Co., Ltd.), and mix evenly to form a PET mixture; the PET mixture and polydodecyl dodecylamide (PA1212, Arkema, France) are double-layered according to the ratio of 70:30 Co-extruded to obtain a 265-micron intermediate layer; then, dry compound a 40-micron-thick polyvinylidene fluoride (PVDF, Arkema, France) film on the PET surface, and melt-coat a 400-micron-thick ethylene-vinyl acetate on the PA1212 surface Copolymer (EVA) film. The composition of the EVA film is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com