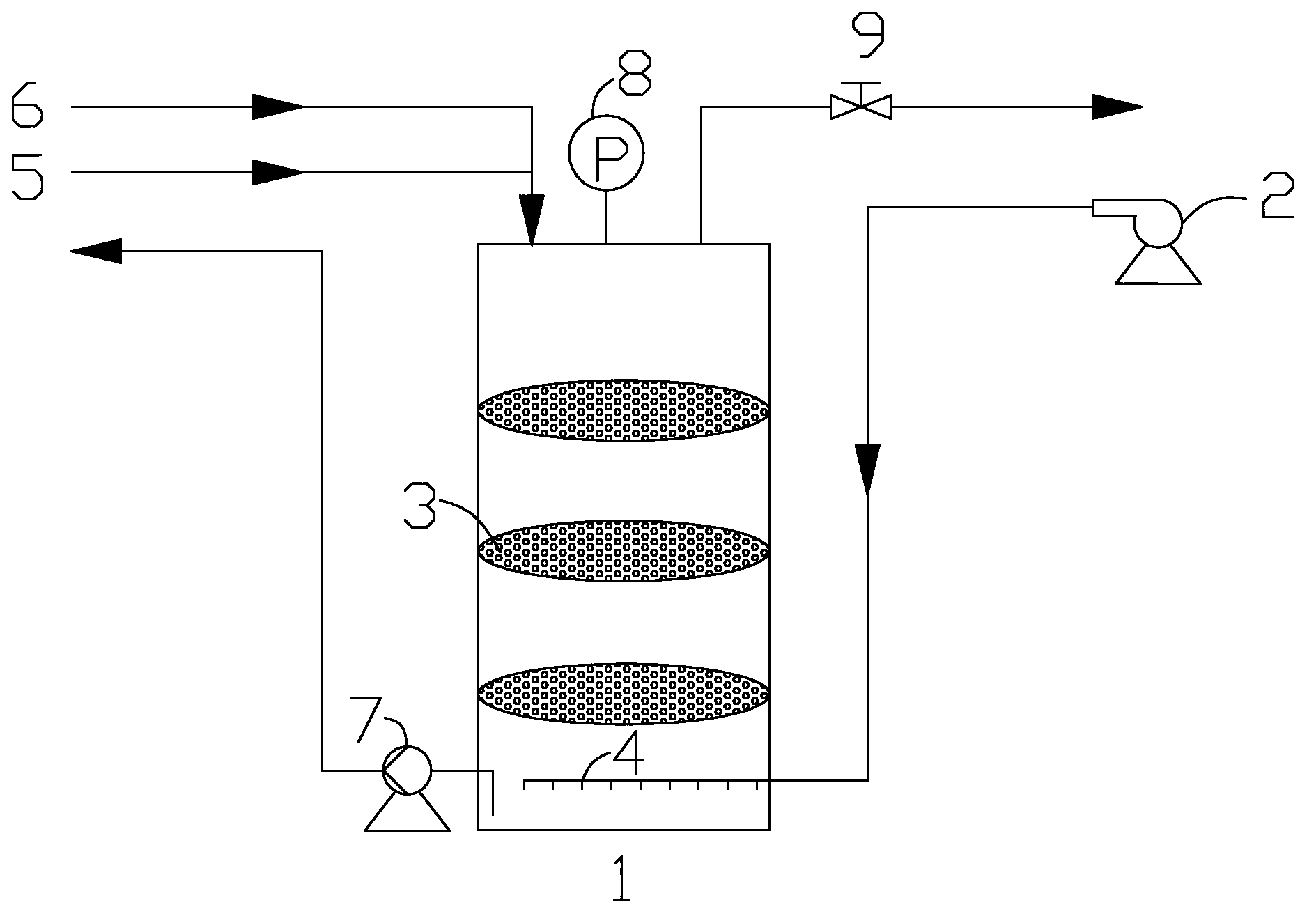

Ammonium sulfite oxidation process and device

An oxidation device, the technology of ammonium sulfite, is applied in the chemical method, ammonia compound, inorganic chemistry and other directions of reacting liquid and gas medium, which can solve the problem of reducing the oxidation rate, achieve the improvement of the oxidation rate, prevent the escape of sulfur dioxide, prevent the The effect of ammonia escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A sintering plant, 2 sets 260m 2 The sintering flue gas ammonia desulfurization project adopts this oxidation process, and the SO in the flue gas 2 The concentration is 2316mg / m 3 , the pH value of the slurry at the entrance of the oxidation tank is controlled at 7.0, the flow rate of the slurry in the oxidation tank is 40m / h, the O / S ratio of the oxidation air is controlled at 3, the outlet aperture of the oxidation air pipe is 8mm, the distance between the porous plates is 2.0m, and 2 layers The hole diameter of the porous plate is 10mm, the distance between the holes is 30mm, and the pressure at the top of the oxidation tank is controlled at 0.05MP. The oxidation rate of the slurry out of the tank is 99.8%, and the concentration of ammonium sulfate in the slurry after oxidation is 33.7%.

Embodiment 2

[0056] In a thermal power plant, the flue gas ammonia desulfurization project of two 135WM units adopts this oxidation process, and the SO in the flue gas 2 The concentration is 3560mg / m 3 , the pH value of the slurry at the entrance of the oxidation tank is controlled at 7.1, the flow rate of the slurry in the oxidation tank is 45m / h, the O / S ratio of the oxidation air is controlled at 3, the outlet aperture of the oxidation air pipe is 10mm, the distance between the porous plates is 2.0m, and 3 layers The hole diameter of the perforated plate is 10mm, the hole center distance is 40mm, and the pressure at the top of the oxidation tank is controlled at 0.05MP. The oxidation rate of the slurry out of the tank is 99.9%, and the concentration of ammonium sulfate in the slurry after oxidation is 32.6%.

Embodiment 3

[0058] A self-provided power plant, a 410t / h boiler flue gas ammonia desulfurization project adopts this oxidation process, the SO in the flue gas 2 The concentration is 1830mg / m 3 , the pH value of the slurry at the entrance of the oxidation tank is controlled at 7.0, the flow rate of the slurry in the oxidation tank is 50m / h, the O / S ratio of the oxidation air is controlled at 3, the outlet aperture of the oxidation air pipe is 10mm, the distance between the porous plates is 2.0m, and 2 layers The hole diameter of the perforated plate is 10mm, the hole center distance is 35mm, and the pressure at the top of the oxidation tank is controlled at 0.05MP. The oxidation rate of the slurry out of the tank is 99.9%, and the concentration of ammonium sulfate in the slurry after oxidation is 33.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com