Daptomycin separation and purification method

A technology for separation and purification of daptomycin, applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve problems such as difficult large-scale production, acid hydrolysis of daptomycin, and high operating costs, and achieve Easy recycling and reuse, low toxicity, and low production and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

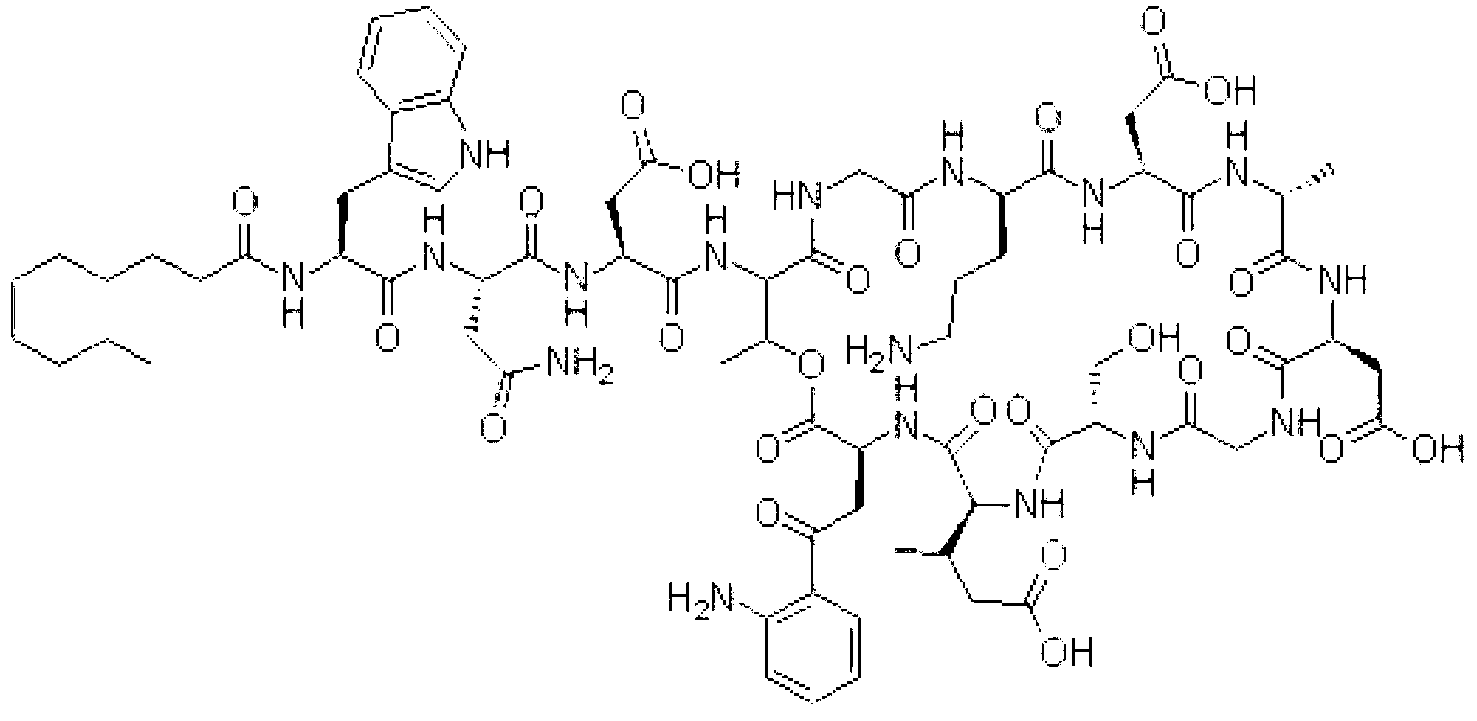

Image

Examples

Embodiment 1

[0039] a. Take 200L of daptomycin fermentation broth (hereinafter referred to as fermentation broth), adjust the pH of the fermentation broth to 3.5 with oxalic acid, add 3kg of perlite, stir evenly, filter by plate and frame to obtain mycelial broth;

[0040] b. Add the mycelium liquid to the butanol solution, soak for 2 hours, filter, and collect the filtrate; add sodium chloride with a mass volume ratio of 1% to the filtrate to demulsify, and after standing for layering, collect the alcohol phase extract;

[0041] c. Add 70g / L dipotassium hydrogen phosphate solution to the alcohol phase extract for extraction, adjust the pH to 7-10, transfer the daptomycin to the water phase, and collect the water phase solution after standing for layering;

[0042] d. Add 0.2% activated carbon to the aqueous phase solution, stir for 30 minutes, and filter to obtain the decarburization filtrate; adjust the decarburization filtrate to pH 5.8 with citric acid, then add butanol extraction, daptomycin ...

Embodiment 2

[0048] a. Take 200L of daptomycin fermentation broth, adjust the pH of the fermentation broth to 2.61 with citric acid, add 4000g perlite to the above fermentation broth, stir evenly, plate and frame filtration, and collect the mycelial broth.

[0049] b. Soak the hypha in n-butanol for 2 hours, filter to obtain the n-butanol solution, add 1.5% NaCl to demulsify the n-butanol solution, and collect the n-butanol alcohol phase after separation.

[0050] c. Add 50g / L sodium bicarbonate solution to the alcohol phase extract for extraction, adjust the pH to 7.15, transfer the daptomycin into the water phase, and collect the water phase solution after standing for layering;

[0051] d. Add 0.5% activated carbon to the aqueous solution, stir for 60 minutes, and filter to obtain a decarburization filtrate; adjust the decarburization filtrate to pH 5.3 with citric acid, and then add n-butanol for extraction, and daptomycin is converted into n-butanol Phase, collect the n-butanol extract;

[00...

Embodiment 3

[0057] a. Take 200L of daptomycin fermentation broth (hereinafter referred to as fermentation broth), adjust the pH of the fermentation broth to 3.5 with hydrochloric acid, add 3kg of diatomaceous earth, stir evenly, filter plate and frame to obtain mycelial broth;

[0058] b. Add the mycelium liquid to the 1-pentanol solution, soak for 2 hours, filter, and collect the filtrate; add 1% sodium sulfate in mass / volume concentration to the filtrate to demulsify, and after standing for layering, collect the alcohol phase extract;

[0059] c. Add 70g / L sodium bicarbonate solution to the alcohol phase extract for extraction, adjust the pH to 7-10, transfer the daptomycin into the water phase, stand for layering, and collect the water phase solution;

[0060] d. Add activated carbon with a mass / volume concentration of 0.2% to the aqueous phase solution, stir for 30 minutes, and filter to obtain a decarburization filtrate; adjust the decarburization filtrate to pH 5.8 with citric acid, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com