Chitosan phosphorylation modification method

A technology of chitosan and phosphorylation, which is applied in the field of biochemical industry to achieve the effects of high yield, simple and easy operation, and high degree of substitution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

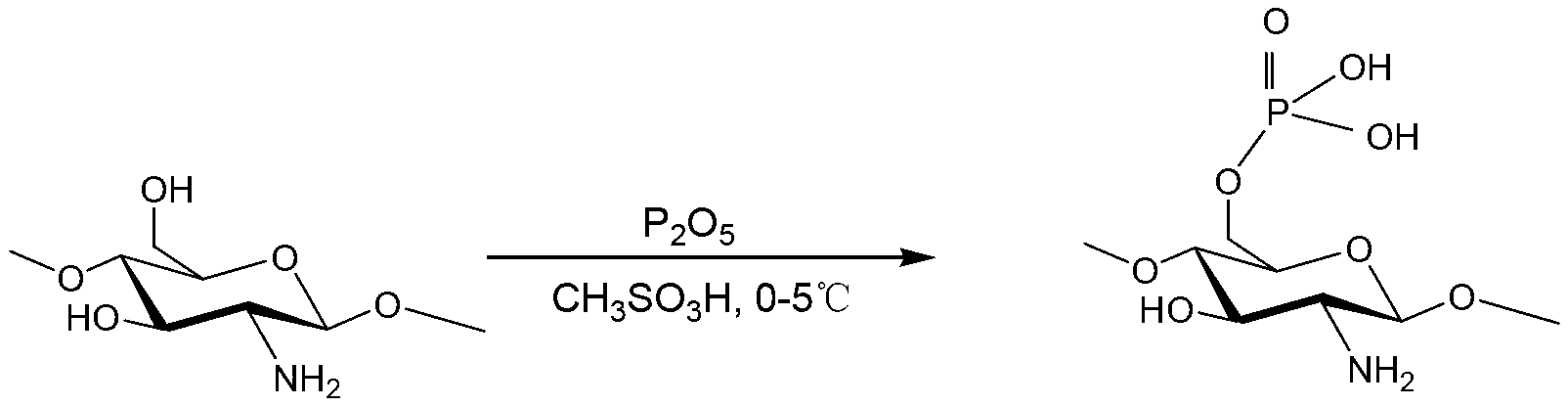

Method used

Image

Examples

Embodiment 1

[0020] Mix 2g of chitosan and 14ml of methanesulfonic acid evenly, then add 6g of phosphorus pentoxide, under the protection of nitrogen, keep mechanical stirring at 2°C for 2 hours; add 70ml of ether to the obtained reaction system for precipitation, centrifuge . Then wash the precipitate with 42ml acetone and 42ml methanol successively. The precipitate was then dissolved with 50 ml of deionized water. The turbid liquid was dialyzed with a molecular weight cut-off of 6000, then concentrated in vacuum, and the concentrated liquid was freeze-dried to obtain the product.

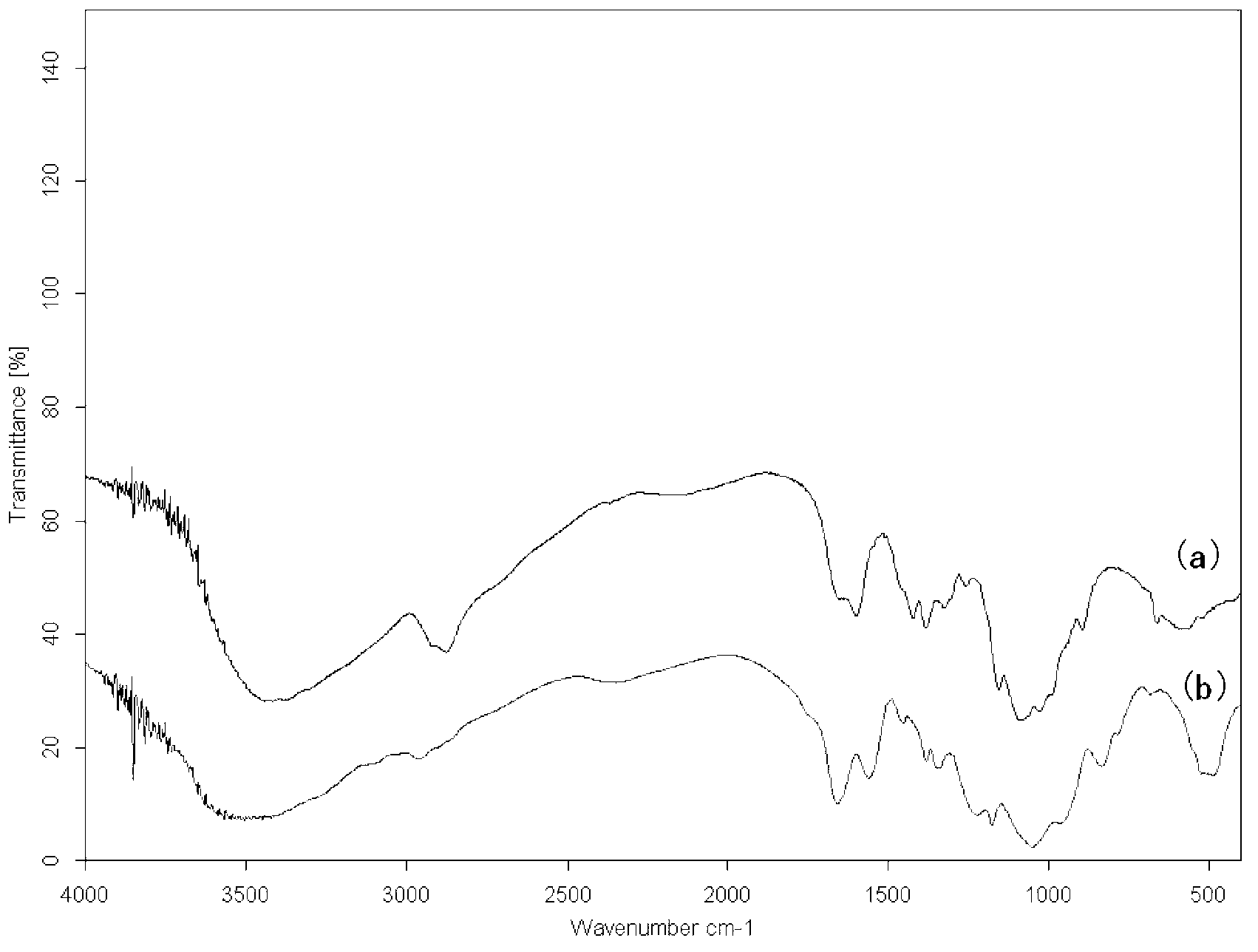

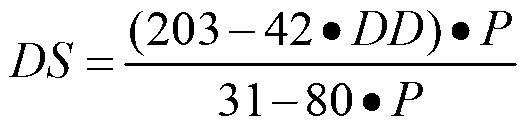

[0021] figure 1 Be the infrared spectrum contrast figure of chitosan and embodiment 1 gained phosphorylated chitosan, wherein figure 1 (a) is the infrared spectrogram of chitosan, figure 1 (b) is the infrared spectrogram of embodiment 1 gained phosphorylated chitosan. For chitosan, 3500-3400cm -1 It is the stretching vibration absorption band of hydroxyl OH; 2878cm -1 is the methine CH on the sugar ring...

Embodiment 2

[0033] Mix 3g of chitosan and 21ml of methanesulfonic acid evenly, then add 8g of phosphorus pentoxide, under the protection of nitrogen, keep mechanically stirring at 4°C, then slowly add 2g of phosphorus pentoxide, and react for 3 hours; Add 100 ml of diethyl ether to the resulting reaction system for precipitation and centrifugation. Then wash with 60ml acetone and 60ml methanol successively. Then dissolve the precipitate with 80ml deionized water. The turbid liquid was dialyzed with a molecular weight cut-off of 3500, then concentrated in vacuum, and the concentrated liquid was freeze-dried to obtain the product.

[0034] After testing, the degree of substitution of the obtained phosphorylated chitosan was 1.27.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com