Sodium-sulfur electrical storage battery

A technology of storage batteries and sodium-sulfur batteries, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of restricting the commercial scale application of sodium-sulfur batteries, increasing operating costs, high operating temperature, etc., to broaden the commercial The effect of large-scale application range, production cost reduction and operation cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

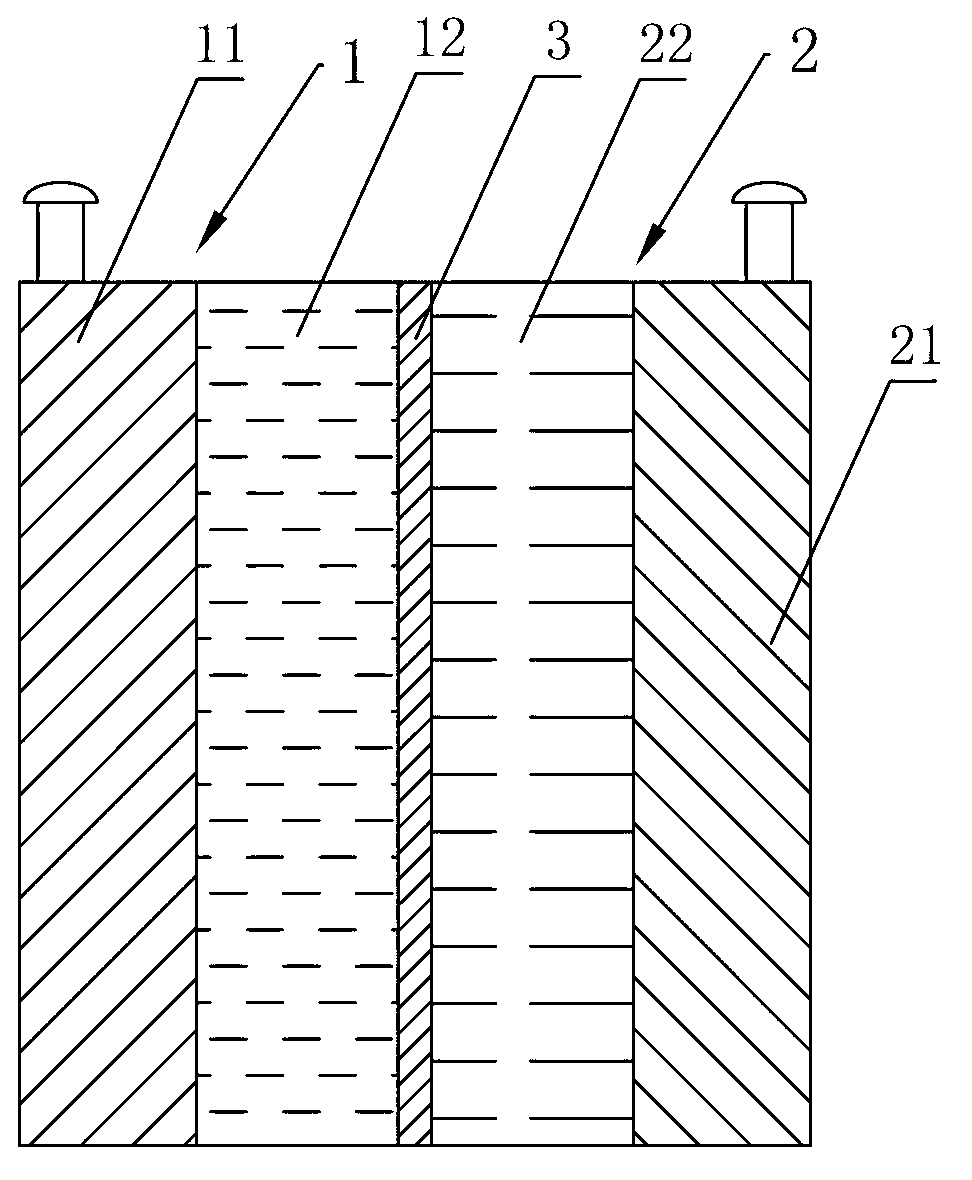

Image

Examples

Embodiment 1

[0039]Add 50 ml of sodium hydroxide solution with a molar concentration of 10 mol / l into a 150 ml Teflon self-sealing bottle, add 0.20 g of titanium dioxide powder (Degussa P25), and after 7 days of hydrothermal reaction at 160 ° C, the resulting white slurry After pickling and washing with deionized water, the material is poured onto a polyethylene film, baked at 100°C for 10 hours, and then sintered at a temperature above 500°C to remove the polyethylene film to obtain sodium titanate inorganic nanofibers membrane.

Embodiment 2

[0041] Add 50 ml of sodium hydroxide solution with a molar concentration of 10 mol / l into a 150 ml sealed container, add 0.20 g of titanium dioxide powder (Degussa P25), and after 6 days of hydrothermal reaction at 165 ° C, the resulting white slurry is passed through After pickling and washing with deionized water, cover evenly on whatman brand filter paper, first bake at 80°C for 15 hours, and then sinter at 520°C to remove the filter paper to obtain sodium titanate inorganic nanofiber membrane.

Embodiment 3

[0043] The anode of the sodium-sulfur battery is composed of 1.2g of solid metal sodium and 5ml of 1-ethyl-3-methylimidazolium chloride salt, the cathode of the battery is composed of 2g of solid sulfur and 5ml of xylidine, and 1-ethyl-3 -Methylimidazolium chloride salt solution forms the anolyte, and the xylidine solution that has dissolved solid sulfur forms the catholyte, and the anolyte and the catholyte are separated by a sodium ion-conducting membrane; the negative electrode of the battery is an inert metal copper, The positive electrode of the battery is tough and corrosion-resistant graphite; the battery shell is made of polypropylene. The battery is assembled in a nitrogen-filled glove box with controlled humidity. After the battery is assembled and packaged, it is taken out of the glove box, and the battery is charged and discharged using a charging and discharging device. Constantly measured at 50°C, the battery voltage is 1.98V, and the charge and discharge times a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com