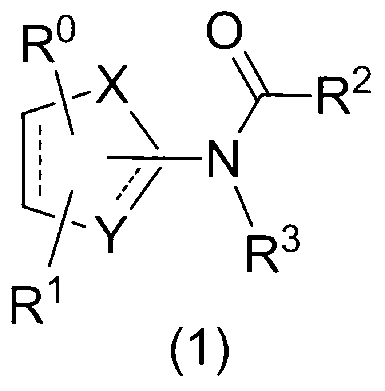

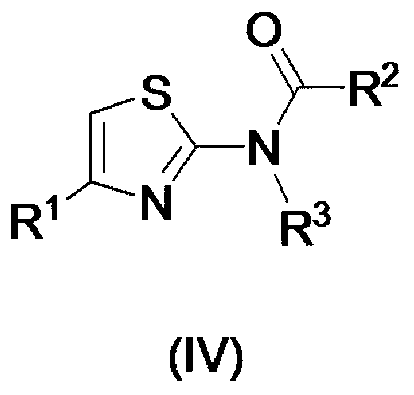

1, 3-thiazole derivative

A technology for thiazole rings and compounds, applied in the field of 2-substituted 1,3-thiazole derivatives and their synthesis, can solve problems such as cumbersome operations and restrictions on the types of substituent groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

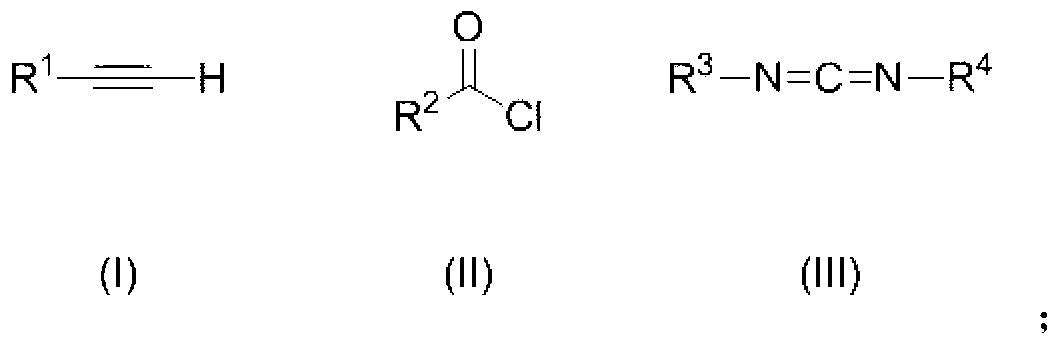

Method used

Image

Examples

Embodiment 1

[0090] Embodiment 1——preparation formula IVa (R 1 = Ph, R 2 =4-CF 3 -Ph,R 3 =Et) compound:

[0091]

[0092] IVa

[0093] Under the protection of nitrogen, add 1mmol phenylacetylene to a 20mL reaction tube containing 2mL ether, use a dry ice-acetone bath to keep the reaction temperature at -78°C, add 1mmol n-butyllithium dropwise, and react for half an hour after the addition is complete. Add 0.125mmol S 8 , naturally warming up to 25°C, and reacting with magnetic stirring for two hours. Under nitrogen protection, 1 mmol of N-tert-butyl-N-ethylcarbodiimide and 1 mmol of p-trifluoromethylbenzoyl chloride were added to a 20 mL reaction tube filled with 3 mL of diethyl ether, and reacted at 25° C. for 48 h. The above two reaction solutions were mixed and reacted at 80° C. for 10 hours. The reaction solution was concentrated, decolorized and separated on a silica gel column, and a mixed solvent of petroleum ether:dichloromethane=1:1 was used as an eluent to obtain a thia...

Embodiment 2

[0094] Embodiment 2——preparation formula IVb (R 1 =2-Me-Ph, R 2 =4-CF 3 -Ph, R 3 =Et) compound:

[0095]

[0096] IVb

[0097] Under the protection of nitrogen, add 1mmol of o-methylphenylacetylene to a 20mL reaction tube containing 2mL of ether, use a dry ice-acetone bath to keep the reaction temperature at -78°C, add 1mmol of n-butyllithium dropwise, and react after the addition is complete. Half an hour, add 0.125mmol S 8 , naturally warming up to 25°C, and reacting with magnetic stirring for two hours. Under nitrogen protection, 1 mmol of N-tert-butyl-N-ethylcarbodiimide and 1 mmol of p-trifluoromethylbenzoyl chloride were added to a 20 mL reaction tube filled with 3 mL of diethyl ether, and reacted at 25° C. for 48 h. The above two reaction solutions were mixed and reacted at 60° C. for 10 hours. The reaction solution was concentrated, decolorized and separated on a silica gel column, and a mixed solvent of petroleum ether:dichloromethane=1:1 was used as an elue...

Embodiment 3

[0098] Embodiment 3——preparation formula IVc (R 1 =3-Cl-Ph,R 2 =4-CF 3 -Ph,R 3 =Et) compound:

[0099]

[0100] IVc

[0101] Under nitrogen protection, add 1mmol m-chlorophenylacetylene to a 20mL reaction tube containing 2mL ether, use a dry ice-acetone bath to keep the reaction temperature at -78°C, add 1mmol n-butyllithium dropwise, and react halfway after the addition is complete. hour, add 0.125mmol S 8 , naturally warming up to 25°C, and reacting with magnetic stirring for two hours. Under nitrogen protection, 1 mmol of N-tert-butyl-N-ethylcarbodiimide and 1 mmol of p-trifluoromethylbenzoyl chloride were added to a 20 mL reaction tube filled with 3 mL of diethyl ether, and reacted at 25° C. for 48 h. The above two reaction solutions were mixed and reacted at 100° C. for 10 hours. The reaction solution was concentrated, decolorized and separated on a silica gel column, and a mixed solvent of petroleum ether:dichloromethane=1:1 was used as an eluent to obtain a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com