A kind of synthetic method of triisopropyl chlorosilane

A technology of triisopropyl silane and propyl chlorosilane, which is applied in the field of chemical synthesis technology of triisopropyl chlorosilane, can solve the problems of difficulty in obtaining triisopropyl chlorosilane, many side reactions, etc. The effect of industrialization promotion, high product yield and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Step 1: Preparation of Triisopropylsilanol

[0022] In a 500ml four-neck flask equipped with a stirrer, a thermometer, and a condenser tube, add 158.3g (1mol) of triisopropylsilane and 0.1 to 50% of a catalyst (iodine or bromine or metal halide MX or hydrogen halide One, X is Cl, Br or I), under nitrogen protection, add 68g (1mol) of hydrogen peroxide with a concentration of 50% dropwise at 70-110°C for about 4 hours, keep warm at 70-110°C for 2 hours, then cool down After reaching room temperature, let stand for 1 hour, and separate the water phase to obtain 174 g of triisopropylsilanol. Analysis of the product by gas chromatography showed a content of 99.5%.

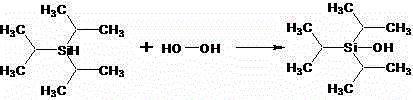

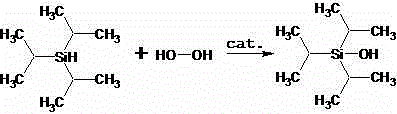

[0023] This step reaction formula is as follows:

[0024]

[0025] The above hydrogen peroxide can be replaced by one of peracetic acid, potassium ferrate, potassium chlorate, sodium chlorate, sodium hypochlorite or more than one mixed oxidant.

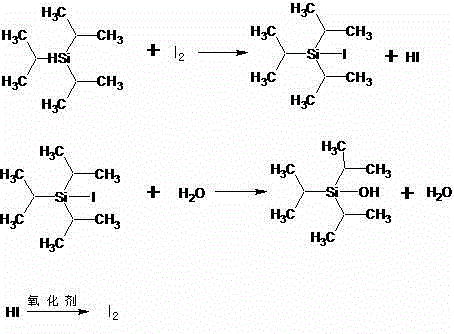

[0026] The reaction mechanism of catalyzer is as follows (ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com