A kind of solvent-free nano epoxy anti-corrosion coating and preparation method thereof

A technology of anti-corrosion coatings and nano-rings, applied in anti-corrosion coatings, epoxy resin coatings, carboxyl rubber coatings, etc., can solve the problems of difficult dispersion of coatings, increase coating toughness, poor dispersion stability, etc., achieve good metal adhesion, improve coating Effects of layer life and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Prepare nano-titanium dioxide dispersion liquid, the raw material parts used are as follows:

[0025] 2 grams of nano-titanium dioxide;

[0026] Coupling agent KH-5503 grams;

[0027] 10 grams of isopropanol;

[0028] Preparation process: weigh 2g of dried nano-TiO 2 For the powder, prepare it into a suspension with 5g of isopropanol solution, disperse at high speed (800r / min) for 30min, then disperse in an ultrasonic field for 30min, and transfer it into a three-necked flask. At the same time, 3 g of coupling agent KH-550 was mixed with the remaining isopropanol solution, and stirred with a magnetic stirrer (600 r / min) for 15 min at room temperature. Mix the above two solutions, disperse in the ultrasonic field for 30min, and then stir in a constant temperature water bath at 80°C (600r / min) for coupling reaction for 2h to prepare nano-TiO 2 Dispersions.

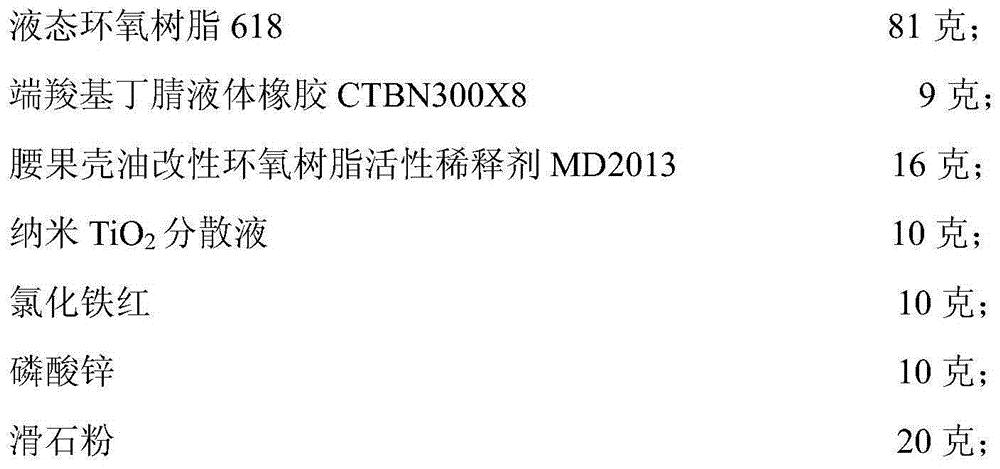

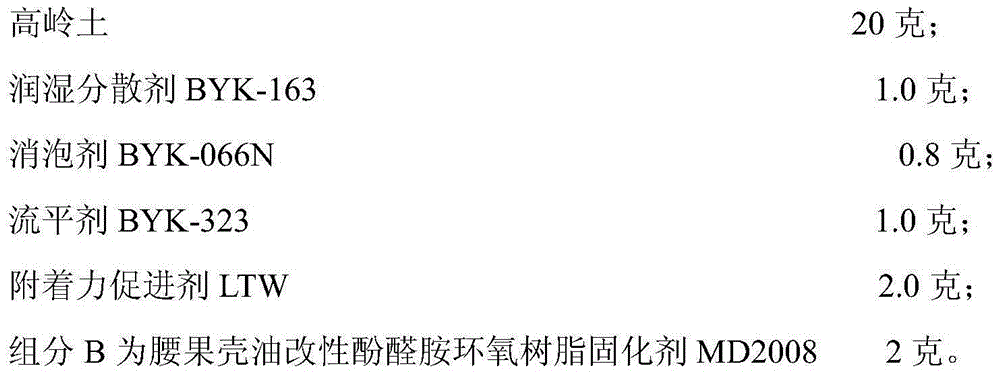

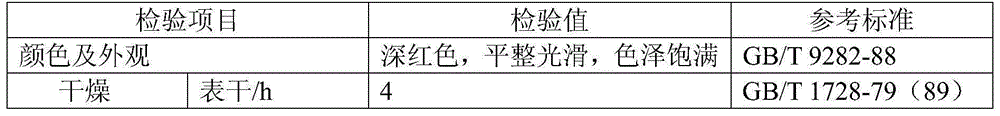

[0029] (2) Preparation of Component A: The used raw material parts for the preparation of Component A are as...

Embodiment 2

[0039] Prepare a kind of agent-free nano epoxy anticorrosion coating, the steps are as follows:

[0040] (1) Prepare nano-titanium dioxide dispersion liquid, the raw material parts used are as follows:

[0041] 2 grams of nano-titanium dioxide;

[0042] Coupling agent KH-5603 grams;

[0043] 10 grams of ethanol;

[0044] Preparation process: weigh 2g of dried nano-TiO 2 For the powder, use 5g of ethanol solution to prepare it into a suspension, disperse at high speed (780r / min) for 30min, then disperse in an ultrasonic field for 30min, and transfer it into a three-neck flask. At the same time, 3 g of coupling agent KH-560 was mixed with the remaining ethanol solution, and stirred with a magnetic stirrer (580 r / min) for 15 min at room temperature. Mix the above two solutions, disperse in the ultrasonic field for 30min, and then stir in a constant temperature water bath at 80°C (580r / min) for coupling reaction for 2h to prepare nano-TiO 2 Dispersions.

[0045] (2) Preparat...

Embodiment 3

[0054] Prepare a kind of agent-free nano epoxy anticorrosion coating, the steps are as follows:

[0055] (1) Prepare nano-titanium dioxide dispersion liquid, the raw material parts used are as follows:

[0056] 2 grams of nano-titanium dioxide;

[0057] Coupling agent KH-5703 grams;

[0058] 10 grams of ethanol;

[0059] Preparation process: weigh 2g of dried nano-TiO 2 For the powder, use 5g of ethanol solution to prepare it into a suspension, disperse at high speed (760r / min) for 30min, then disperse in an ultrasonic field for 30min, and transfer it into a three-necked flask. At the same time, 3 g of coupling agent KH-570 was mixed with the remaining ethanol solution, and stirred with a magnetic stirrer (500 r / min) for 15 min at room temperature. Mix the above two solutions, disperse in the ultrasonic field for 30min, and then stir in a constant temperature water bath at 80°C (500r / min) for coupling reaction for 2h to prepare nano-TiO 2 Dispersions.

[0060] (2) Prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com