Transparent handmade soap and preparation method thereof

A handmade soap, transparent technology, applied in the direction of chemical instruments and methods, soap detergent composition, surface active non-soap compound and washing composition, etc., can solve the problems of large loss of fragrance, soap body pollution, taste variation, etc., to achieve It is not easy to turn black, save the amount of use, and avoid the effect of taste variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

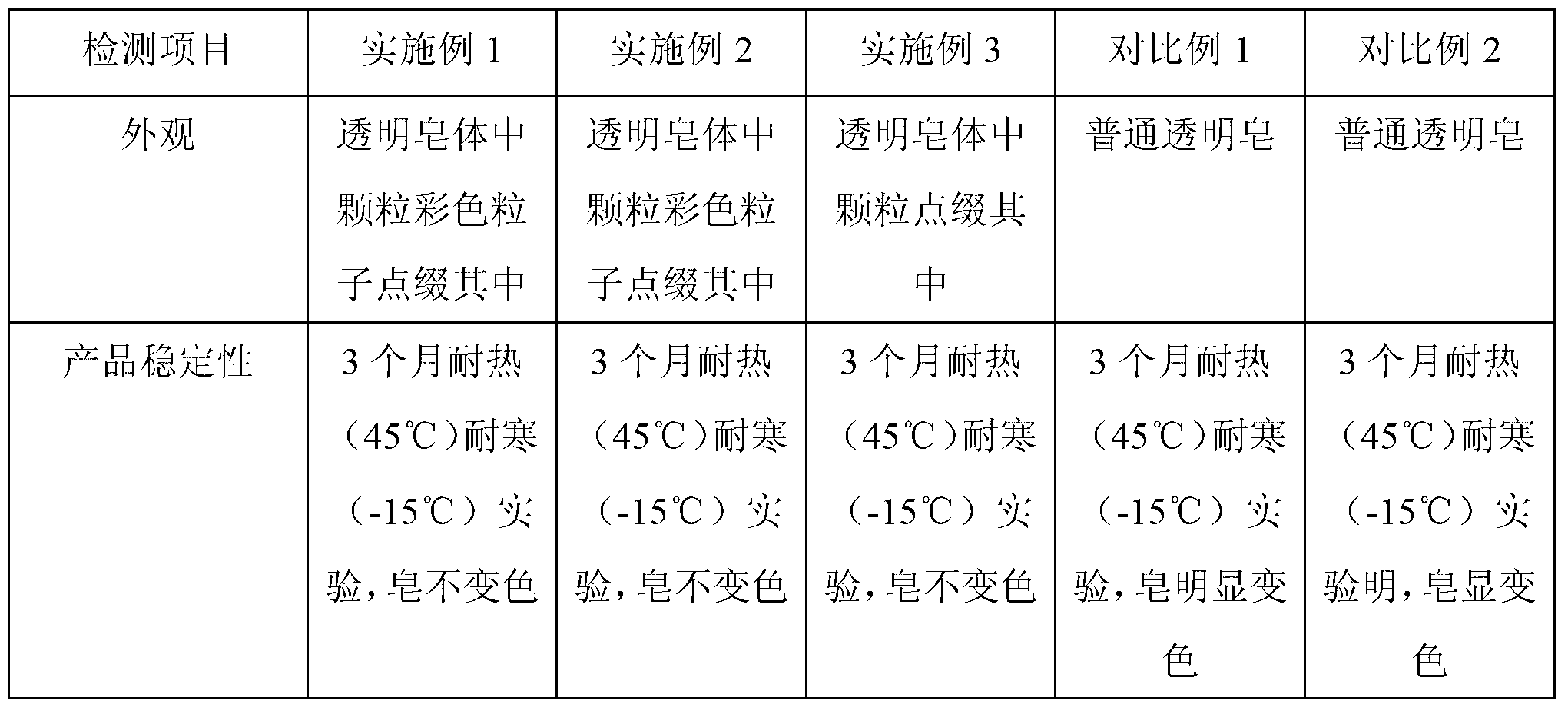

Embodiment 1

[0023] (1) Weigh each component according to the formula in Table 1 below; the wall thickness of the encapsulated particles used in the formula is 0.25-0.35mm, and the capsule core of the encapsulated particles accounts for 30-40% of the weight of the entire encapsulated particles. The particle size of the capsule particle is 0.5-0.8 mm. The capsule wall is made of cellulose acetate butyl, and the capsule core is rose extract. The fatty acid used in the formula is a combination of stearic acid, lauric acid and myristic acid in a mass ratio of 3:1:2. The humectant used in the formula is a combination of glycerin and corn propylene glycol (referring to propylene glycol derived from corn) in a mass ratio of 1:2. The penetrating agent used in the formula is white granulated sugar. The surfactant used in the formulation is potassium glycinate of coconut oil fatty acid.

[0024] (2) Put the fatty acid and humectant into the stirring pot according to the ratio, heat and stir to ra...

Embodiment 2

[0026] (1) Weigh each component according to the formula in Table 1 below. The wall thickness of the encapsulated particles used in the formula is 0.35-0.45mm, and the core of the encapsulated particles accounts for 40-50% of the weight of the entire encapsulated particles. The particle size of the capsule particle is 0.8-1 mm. The capsule wall is made of polyoxyethylene, and the capsule core is composed of VE oil, rose essential oil, oil-soluble rosemary extract and red pigment accounting for 1 wt% of the capsule core material in a mass ratio of 1:1:1. The fatty acid used in the formula is a combination of stearic acid and lauric acid in a mass ratio of 1:1. The moisturizing agent used in the formula is a combination of glycerin, sorbitol and propylene glycol in a mass ratio of 8:15:13. The penetrating agent used in the formula is white granulated sugar. The surfactant used in the formula is disodium fatty alcohol polyoxyethylene ether sulfosuccinate. The caustic used in t...

Embodiment 3

[0029] (1) Weigh each component according to the formula in Table 1 below. The wall thickness of the encapsulated particles used in the formula is 0.41-0.5mm, and the core of the encapsulated particles accounts for 35-45% of the weight of the entire encapsulated particles. The particle size of the capsule particle is 0.6-0.8 mm. The capsule wall is made of cellulose acetate butyl, and the capsule core is made of hyaluronic acid aqueous solution with a mass fraction of 0.02% and ginseng extract, and the mass ratio of the two is 1:1. The fatty acid used in the formula is a combination of stearic acid, myristic acid and palmitic acid in a mass ratio of 2:1:1. The moisturizing agent used in the formula is a combination of glycerin and sorbitol in a mass ratio of 1:2. The penetration enhancer used in the formula is rock sugar. The surfactant used in the formula is disodium fatty alcohol polyoxyethylene ether sulfosuccinate. The caustic used in the formula is sodium hydroxide.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com