Method for determining tributyl phosphate in dry food packaging paper

A technology of tributyl phosphate and food packaging paper, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of accurate qualitative confirmation and quantitative analysis of unfavorable target compounds, false positives, etc., to reduce errors, improve accuracy, The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

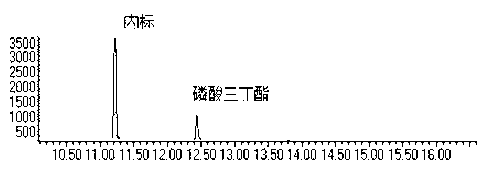

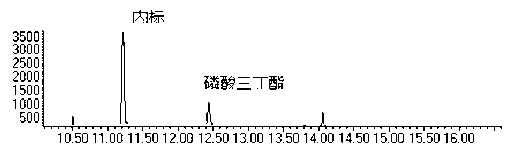

Image

Examples

Embodiment 1

[0028] A method for measuring tributyl phosphate in dry food packaging paper, the specific process is as follows:

[0029] (1) Configuration of internal standard solution

[0030] Accurately weigh 0.2 g of internal standard phenylethyl propionate, and use n-hexane as solvent to dilute to a 100 mL volumetric flask to obtain an internal standard solution with a concentration of 2000 mg / L. Store the internal standard solution in a sealed refrigerator at 4°C, and the validity period is 3 months;

[0031] (2) Configuration of working standard solution

[0032] Accurately weigh 0.2 g of the standard tributyl phosphate, and use n-hexane as the solvent to set the volume to a 100 mL volumetric flask to obtain a standard stock solution with a concentration of 2000 mg / L. Store the standard stock solution in a sealed refrigerator at 4°C, and the validity period is 3 months;

[0033] Accurately pipette 10 μL, 50 μL, 100 μL, 200 μL, 500 μL and 1000 μL of standard stock solution respectiv...

Embodiment 2

[0046] Embodiment 2 Detection of precision and standard addition recovery

[0047] Detection of precision: with a fast food wrapping paper (the measured value was not detected), the content of tributyl phosphate in the spiked sample (the spiked level was 50 mg / kg) was measured in parallel 6 times, and the relative standard deviation was calculated to investigate The precision of the method, the results are shown in Table 1, which shows that the method has good repeatability.

[0048] Table 1 Precision of the method (n=6)

[0049] serial number Measured value (mg / kg) 1 51.41 2 52.05 3 50.64 4 49.74 5 51.08 6 51.17 relative standard deviation(%) 1.52

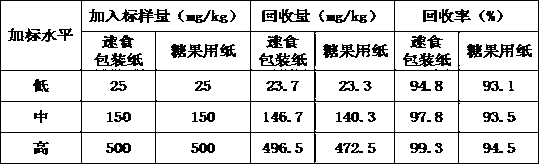

[0050] Detection of spiked recoveries: Two representative samples (instant food packaging paper and candy paper) were selected as spiked sample matrices, and spiked samples with low, medium, and high concentration levels were prepared respectively. The results As shown in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| correlation coefficient | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com