Preparation method of ZnO sol compounded Sn doping ZnO thick films

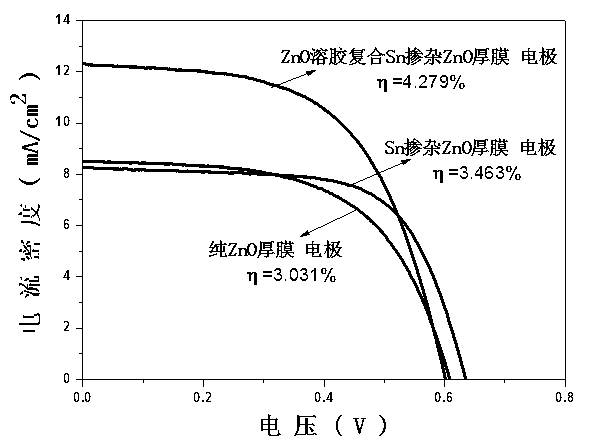

A sol and thick film technology, applied in the direction of photosensitive equipment, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of increasing carrier recombination centers, reducing current, etc., to achieve reduced processing costs, excellent performance, increased The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] A preparation method of ZnO sol composite Sn-doped ZnO thick film, the method comprises the following steps:

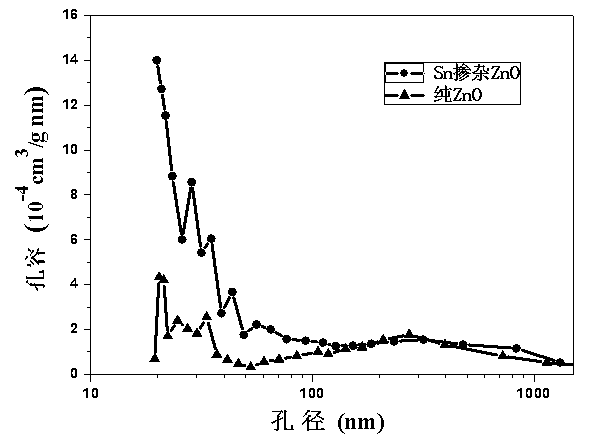

[0025] A. Preparation of Sn-doped ZnO powder by hydrothermal method: triblock copolymer P123 as template, zinc acetate dihydrate as precursor, tin tetrachloride pentahydrate as dopant, urea as buffer, water as Solvent and hydrothermal method prepared Sn-doped ZnO powder, in which the molar ratio of Zn to Sn was 9:1. First, dissolve 0.548g of triblock copolymer P123, 0.988g of zinc acetate dihydrate, and 1.5g of urea into 100mL of deionized water, stir well, add 0.175g of tin tetrachloride pentahydrate, continue stirring for 2 hours, and then transfer to the autoclave Inside, heat at 90°C for 24h, and finally filter, dry at 90°C, and anneal at 450°C for 4h to obtain Sn-doped ZnO powder;

[0026] B. Preparation of ZnO sol by Sol-gel method: triblock copolymer P123 as template, zinc acetate dihydrate as precursor, absolute ethanol as solvent, diethanolamine as st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com