Polymer solar battery and preparation method thereof

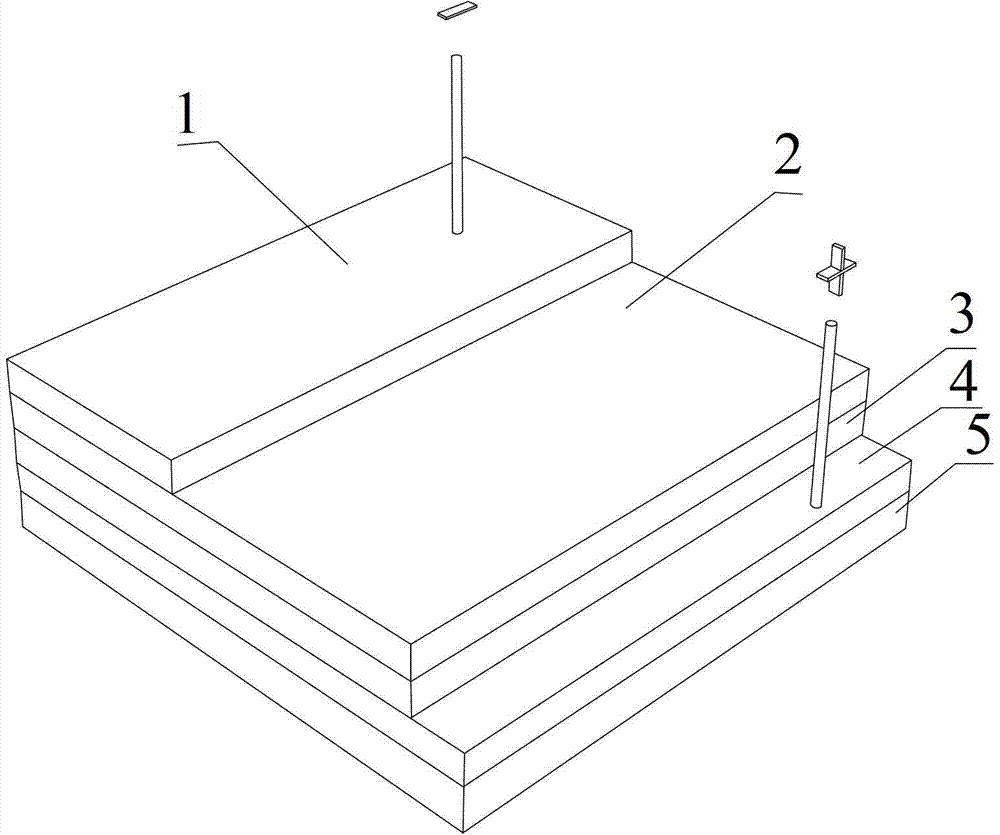

A solar cell and polymer technology, applied in the field of polymer solar cells, can solve problems such as difficult control of solvent gas phase pressure, influence on photoelectric conversion efficiency of devices, and damage to thin film heterojunction structures, etc., to achieve maximum operability and crystallinity improvement , contribute to the effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

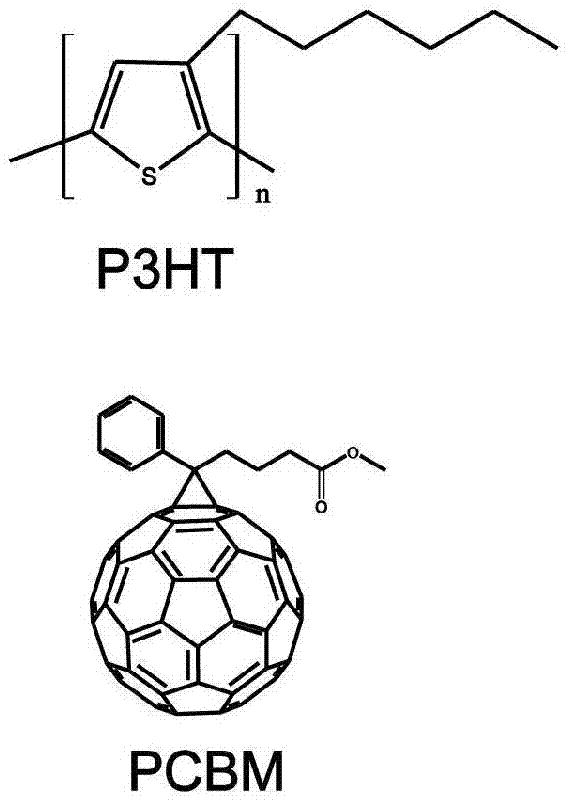

Method used

Image

Examples

Embodiment 1

[0058] 1. Etching, cleaning and pretreatment of ITO glass

[0059] 1.1 Etching and processing of substrate ITO

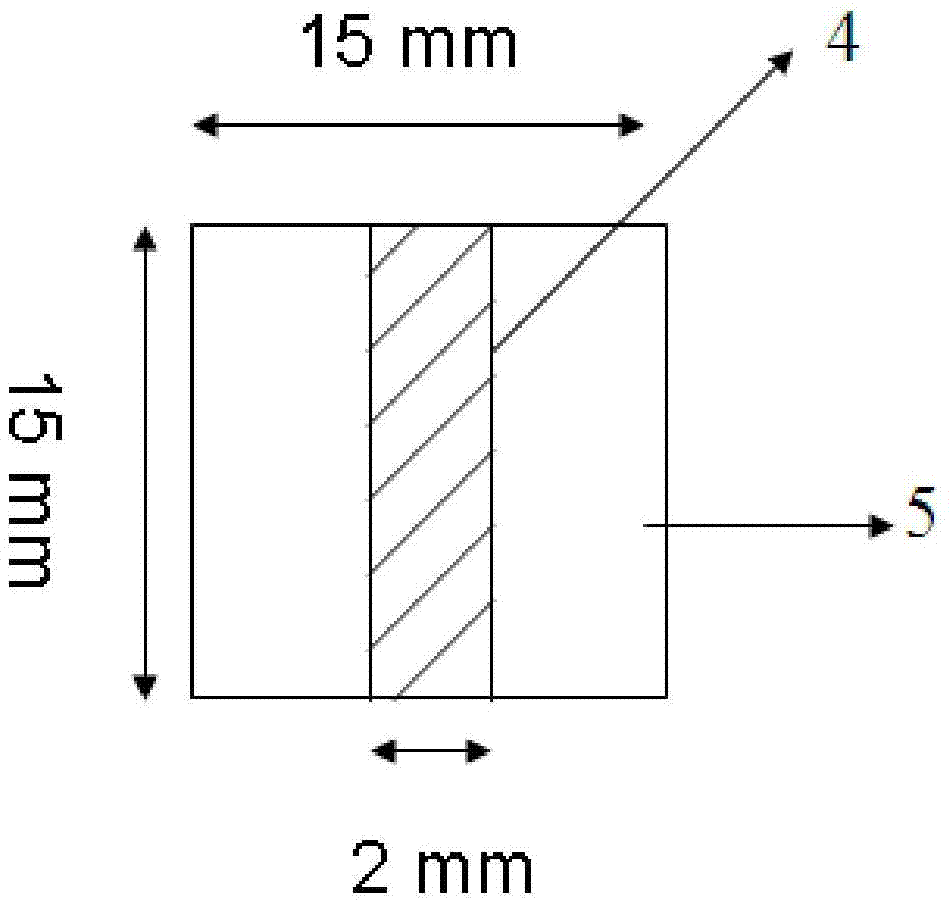

[0060] Use insulating glue to stick the central part of 2mm×15mm on the cut 15mm×15mm regular square ITO glass, the relevant dimensions are as follows figure 2 As shown, make sure there are no air bubbles between the glass and the tape, especially around the edges. Put the pasted ITO glass into the H2 with a concentration of 37%. 2 SO 4 After about 1 minute, take out the ITO glass and wash it several times in deionized water to remove the acid remaining on the glass and complete the etching of ITO.

[0061] 1.2 Cleaning of ITO sheet

[0062] Put the numbered ITO film on the film rack, and clean the surface according to the following steps:

[0063] (1) Detergent cleaning: Use 1% micro-grade solution (Shanghai Shangbi Experimental Instrument Co., Ltd., M-9051) to ultrasonically clean for 10 minutes to wash off the inorganic and organic residues on the ITO slide...

Embodiment 2

[0090] 1. Etching, cleaning and pretreatment of FTO glass

[0091] Same as Example 1.

[0092] 2. Spin coating and annealing of tungsten trioxide

[0093] It is basically the same as Example 1, except that the spin coating speed is 3600 rpm, the thickness is about 45 nm, and the annealing conditions are: 135° C., 20 minutes.

[0094] 3. Preparation of organic photovoltaic active layer

[0095] It is basically the same as Example 1, except that the active layer uses MEH-PPV:PCBM, the solvent is chlorobenzene, the mass ratio of MEH-PPV to PCBM is 1:4, and the spin coating speed is 1200 rpm.

[0096] 4. Self-atmosphere solvent annealing treatment of organic photovoltaic active layer

[0097] Basically the same as in Example 1, the internal pressure of the container during self-atmosphere annealing is maintained at 0.01-1 MPa.

[0098] 5. Evaporation of metal electrodes

[0099] Same as Example 1.

[0100] 6. Heat treatment annealing

[0101] The heat treatment condition is...

Embodiment 3

[0106] 1. Etching, cleaning and pretreatment of ITO glass

[0107] Same as Example 1.

[0108] 2. Spin coating and annealing of cuprous oxide

[0109] It is basically the same as Example 1, except that the spin coating speed is 4100 rpm, the thickness is about 38 nanometers, and the annealing conditions are: 145° C., 10 minutes.

[0110] 3. Preparation of organic photovoltaic active layer

[0111] It is basically the same as Example 1, except that the active layer uses MDMO-PPV:PCBM, the solvent is xylene, the mass ratio of MDMO-PPV to PCBM is 1:2, and the spin coating speed is 500 rpm.

[0112] 4. Self-atmosphere solvent annealing treatment of organic photovoltaic active layer

[0113] Basically the same as in Example 1, the internal pressure of the container during self-atmosphere annealing is maintained at 0.01-1 MPa.

[0114] 5. Evaporation of metal electrodes

[0115] Same as Example 1.

[0116] 6. Heat treatment annealing

[0117] The heat treatment condition is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com