Special polymicro liquid nitrogen leaf fertilizer for vegetable

A technology of liquid nitrogen and foliar fertilizer, applied in the direction of application, fertilization device, fertilizer mixture, etc., can solve the problems of difficult to control the amount of fertilizer, large changes in fertilizer efficiency, complex components, etc., to improve stress resistance and disease resistance, and enhance chlorophyll content , enhance the effect of photosynthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

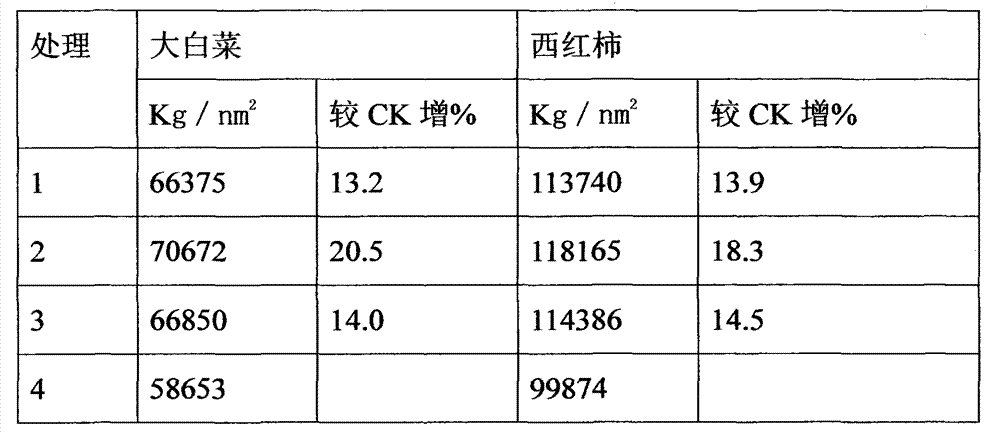

Image

Examples

Embodiment Construction

[0014] A special leaf fertilizer for vegetables with micro liquid nitrogen, including liquid nitrogen and urea, also including boron, amino acid powder and EDTAZn; the content of N in the liquid nitrogen is ≥ 32%, the content of N in the urea is ≥ 46%, The content of B in boron is ≥ 20%, the content of amino acid in the original amino acid powder is ≥ 40%, the content of Zn in EDTAZn is ≥ 14%; the weight percentages of the various components are 40% for liquid nitrogen and 22% for urea , boron is 4%, amino acid powder is 25%, and EDTAZn is 9%; the special foliage fertilizer for vegetables with micro-liquid nitrogen also includes an appropriate amount of rooting agent.

[0015] Configuration process, preparation of raw materials: liquid nitrogen, urea, boron, amino acid powder and EDTAZn (EDTAZn is ethylenediaminetetraacetic acid zinc sodium salt). Among them, the content of N in liquid nitrogen is ≥ 32%, the content of N in urea is ≥ 46%, the content of B in boron is ≥ 20%, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com