Preparation method for 2,2-diisopropyl propionitrile

A technology of propylpropionitrile and propionitrile, which is applied in the field of precursor material 2 of cooling agent WS-23, can solve the problems of unfavorable safety production, long production cycle and low efficiency, and avoid strong corrosion and irritation , Reduce operation steps, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

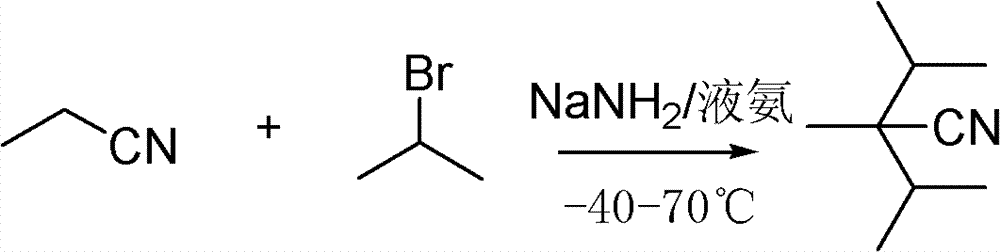

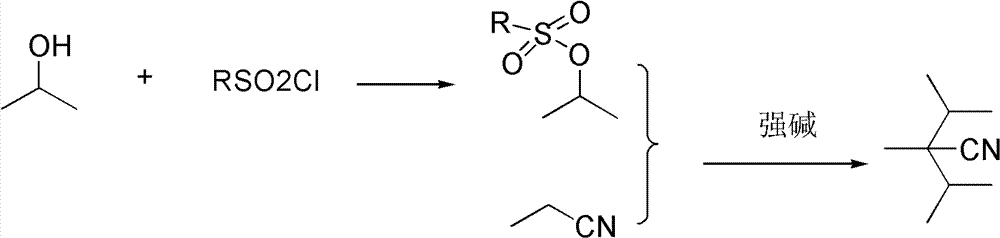

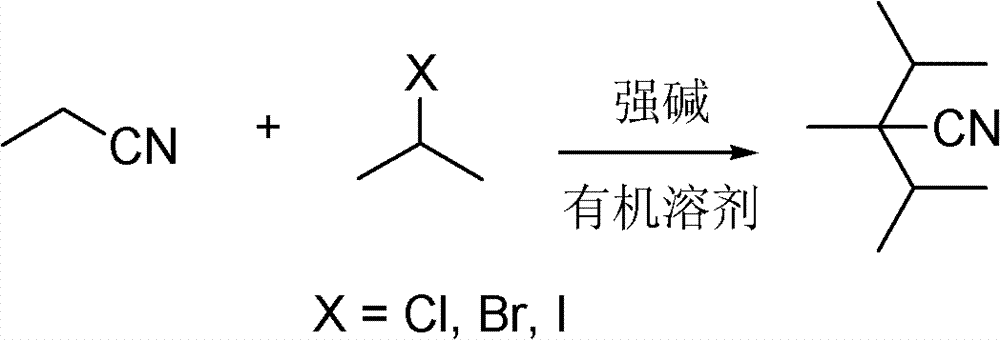

Method used

Image

Examples

Embodiment 1

[0022] Add 300g of diethyl ether into a 1000mL reaction flask, then add 50g of sodium hydride, start stirring to make it evenly stirred, and slowly heat to reflux. 33g of propionitrile and 100g of 2-chloropropane were mixed evenly and added to the dropping funnel, then the mixture was slowly added dropwise into the reaction flask, exothermic during the dropping process, and the reaction was controlled to slowly reflux at 35°C. The dropwise addition time was 3 hours, and after the dropwise addition was completed, reflux was continued at 35° C. for 15 hours. After the reaction is complete, add 50 g of water dropwise to quench excess sodium hydride, separate the organic phase, wash once with 50 g of pure water and saturated brine, separate the water phase, add 10 g of anhydrous sodium sulfate to the organic phase and dry for 3 hours, filter out Crystalline sodium sulfate, normal pressure reclaims solvent, then decompression distills out 75g 2,2 diisopropyl propionitrile, product ...

Embodiment 2

[0024] Add 300g of toluene into a 1000mL reaction flask, then add 40g of calcium hydride, start stirring to make it evenly stirred, and slowly heat to 110°C. 33g of propionitrile and 150g of 2-chloropropane were mixed evenly and added to the dropping funnel, and then the mixture was slowly added dropwise to the reaction flask, exothermic during the dropping process, and the reaction was controlled to slowly reflux at 110°C. The dropwise addition time was 7 hours, and after the dropwise addition was completed, reflux was continued at 110° C. for 20 hours. After the reaction is complete, add 50g of water dropwise to quench excess calcium hydride, separate the organic phase, wash once with 50g of pure water and saturated brine, separate the water phase, add 10g of anhydrous sodium sulfate to the organic phase and dry for 3 hours, filter out Crystallization sodium sulfate, normal pressure reclaims solvent, then decompression distills out 72g 2,2 diisopropyl propionitrile, product ...

Embodiment 3

[0026] Add 250g of dioxane into a 1000mL reaction flask, then add 65g of potassium hydride, start stirring to make it evenly stirred, and slowly heat to reflux. 33g of propionitrile and 240g of 2-iodopropane were mixed evenly and added to the dropping funnel, then the mixture was slowly added dropwise into the reaction flask, exothermic during the dropping process, and the reaction was controlled to slowly reflux at 101°C. The dropping time was 8 hours, and after the dropping was completed, reflux was continued at 101° C. for 10 hours. After the reaction is complete, add 50 g of water dropwise to quench excess potassium hydride, separate the organic phase, wash once with 50 g of pure water and saturated brine, separate the water phase, add 10 g of anhydrous sodium sulfate to the organic phase and dry for 3 hours, filter out Crystallization sodium sulfate, normal pressure reclaims solvent, then decompression distills out 70g 2,2 diisopropyl propionitrile, product is colorless a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com