Acetylation lignin amphiphilic polymer nanometer colloid sphere and preparation method thereof

A technology of amphiphilic polymers and nano colloids, which is applied in the field of fine chemicals, can solve the problems of restricting the research and large-scale application of lignin colloidal materials, restricting lignin-based colloidal substances, complex preparation methods, etc., achieving good application prospects and Market potential, increased utilization value, strong degradability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

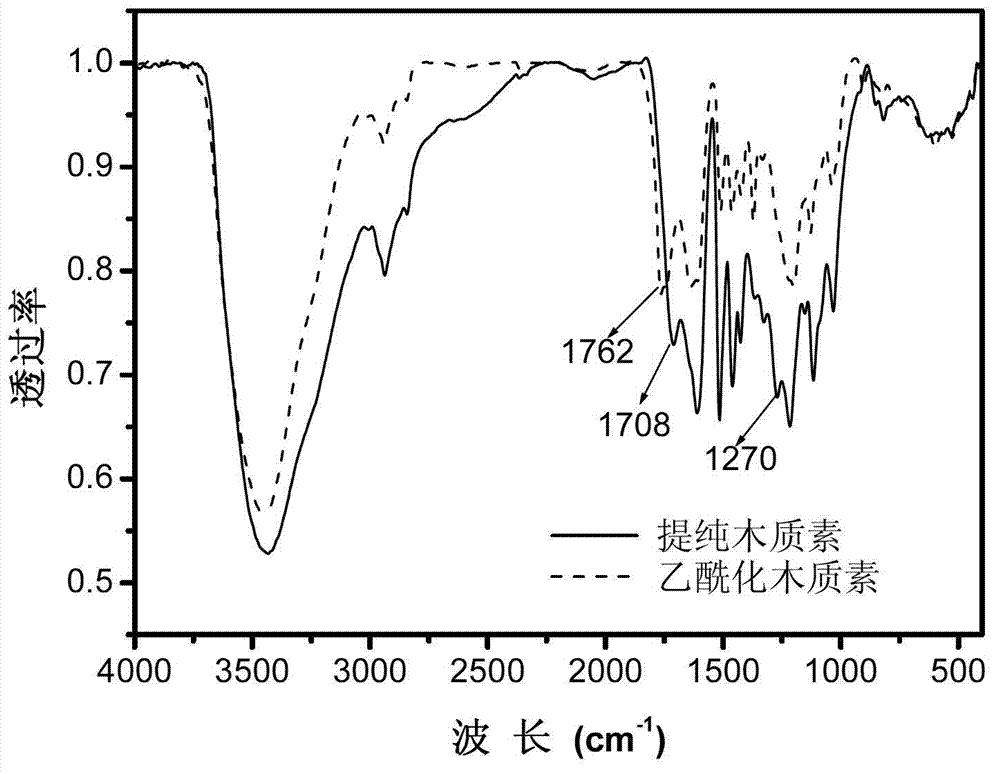

[0022] (1) 0.1g alkaline pulping straw pulp black liquor acid analysis alkali lignin (weight average molecular weight 3640g / mol) is placed in the round bottom flask of 50ml, the mixed solution (alkali of the acetyl bromide of adding 25ml and glacial acetic acid The volume ratio of lignin to acetyl bromide is 1:15), sealed, heated to 50° C. and magnetically stirred for 4 hours to obtain a reaction solution containing acetylated lignin. figure 1 It is the infrared spectrogram of the step acid analysis alkali lignin and the intermediate product acetylated lignin measured by the German Thermo NICOLET 380 infrared spectrophotometer. Such as figure 1 As shown, 1270cm -1 The stretching vibration of the phenolic hydroxyl C-O bond in lignin, 1708cm -1 The stretching vibration of non-conjugated carbonyl in lignin, 1762cm -1 The position is the stretching vibration of the carbonyl after acetylation, indicating that the hydroxyl group in the purified lignin molecule is acetylated, and ...

Embodiment 2

[0032] (1) 0.5g alkaline pulping bamboo pulp black liquor acid analysis alkali lignin (weight average molecular weight 3260g / mol) is placed in the round bottom flask of 50ml, the mixed solution (alkali of the acetyl bromide of adding 25ml and glacial acetic acid The volume ratio of lignin to acetyl bromide is 1:20), sealed, heated to 70° C. and magnetically stirred for 6 hours to obtain a reaction solution containing acetylated lignin.

[0033] (2) The reaction liquid containing acetylated lignin obtained in step (1) is subjected to rotary steaming (the vacuum degree during rotary steaming is 9.0mbar, and the temperature is -10° C.) to obtain acetylated lignin, and the obtained acetylated lignin Dissolve in 5ml tetrahydrofuran to obtain acetylated lignin tetrahydrofuran solution, dilute the solution to a concentration of 4.0g / L with tetrahydrofuran, add 2.5ml distilled water, the weight of distilled water accounts for 33% of the total volume of the solution, stir under normal t...

Embodiment 3

[0035] (1) 0.5g alkaline pulping wood pulp black liquor acid analysis alkali lignin (weight average molecular weight 3500g / mol) is placed in the round bottom flask of 50ml, the mixed solution (alkali of the acetyl bromide of adding 25ml and glacial acetic acid The volume ratio of lignin to acetyl bromide is 1:25), sealed, heated to 55° C. and magnetically stirred for 2.5 hours to obtain a reaction solution containing acetylated lignin.

[0036] (2) The reaction liquid containing acetylated lignin obtained in step (1) is subjected to rotary steaming (the vacuum degree during rotary steaming is 9.0mbar, and the temperature is -10° C.) to obtain acetylated lignin, and the obtained acetylated lignin Dissolve in 5ml tetrahydrofuran to obtain acetylated lignin tetrahydrofuran solution, dilute the solution with tetrahydrofuran to a concentration of 1.0g / L, add 3ml distilled water, the weight of distilled water accounts for 37.5% of the total volume of the solution, stir under normal t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com