Method for improving mechanical property on surface of metal workpiece

A metal workpiece and performance technology, which is applied in the field of improving the surface mechanical properties of metal workpieces, can solve the problems of complicated operation and high preparation cost, and achieve the effects of low preparation cost, simple operation and improved corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

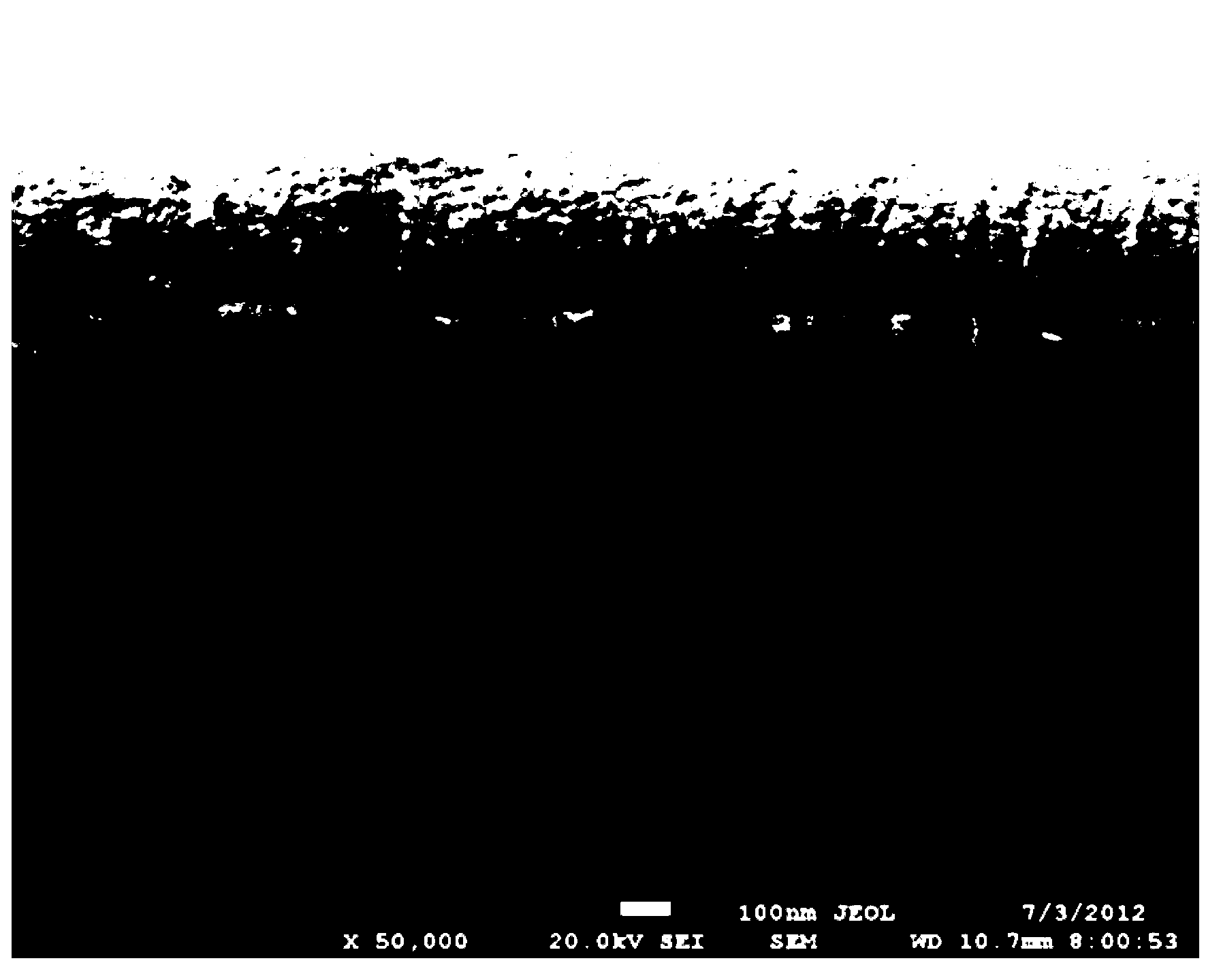

Image

Examples

specific Embodiment approach

[0023] A kind of embodiment of the present invention is: a kind of method that improves the mechanical property of metal workpiece surface, and its concrete steps are:

[0024] A. Put the metal workpiece into the vacuum chamber of the magnetron sputtering equipment, and the vacuum chamber is evacuated to 2×10 -3 Pa;

[0025] B. Introduce argon gas into the vacuum chamber to a pressure of 2.0Pa, apply a DC voltage of -1000V, glow discharge to form plasma, and clean the metal workpiece by sputtering for 30 minutes, then turn off the argon gas and DC power supply;

[0026] C. Introduce nitrogen gas into the vacuum chamber to a pressure of 0.05Pa, and argon gas to a pressure of 0.5Pa, apply a substrate bias voltage of -20V on the metal workpiece, and turn on the power supply of the titanium sputtering target;

[0027] D. Adjust the angle between the surface of the metal workpiece and the normal line of the titanium sputtering target to be 40 degrees, and deposit a 0.2 micron tita...

Embodiment 2

[0031] A kind of embodiment of the present invention is: a kind of method that improves the mechanical property of metal workpiece surface, and its concrete steps are:

[0032] A. Put the metal workpiece into the vacuum chamber of the magnetron sputtering equipment, and the vacuum chamber is evacuated to 1.5×10 -3 Pa;

[0033] B. Introduce argon gas into the vacuum chamber to a pressure of 0.5Pa, apply a DC voltage of -900V, glow discharge to form plasma, and perform sputter cleaning on the metal workpiece for 100 minutes, then turn off the argon gas and DC power supply;

[0034] C. Introduce oxygen into the vacuum chamber to a pressure of 0.10Pa, and argon to a pressure of 1.5Pa, apply a substrate bias of -150V on the metal workpiece, and turn on the power supply of the titanium sputtering target;

[0035] D. Adjust the angle between the surface of the metal workpiece and the normal line of the titanium sputtering target to be 20 degrees, and deposit a 0.1 micron titanium ox...

Embodiment 3

[0040] A kind of embodiment of the present invention is: a kind of method that improves the mechanical property of metal workpiece surface, and its concrete steps are:

[0041] A. Put the metal workpiece into the vacuum chamber of the magnetron sputtering equipment, and the vacuum chamber is evacuated to 0.5×10 -3 Pa;

[0042] B. Introduce argon gas into the vacuum chamber to a pressure of 1.5Pa, apply a DC voltage of -800V, glow discharge to form plasma, and clean the metal workpiece by sputtering for 10 minutes, then turn off the argon gas and DC power supply;

[0043] C. Introduce acetylene to the vacuum chamber to a pressure of 0.10Pa, and argon to a pressure of 2.0Pa, apply a substrate bias of -200V on the metal workpiece, and turn on the power supply of the titanium sputtering target;

[0044] D. Adjust the angle between the surface of the metal workpiece and the normal line of the titanium sputtering target to be 70 degrees, and sputter and deposit a 0.15 micron titani...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap