Acetate-grade pulp and preparation method thereof

A technology of vinegaring and pulping, applied in pulp bleaching, pulping with inorganic alkali, raw material pretreatment, etc., can solve the problems of unstable quality, incomplete qualification, and deterioration of reaction performance, so as to achieve easy process control and high cost , high environmental protection and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

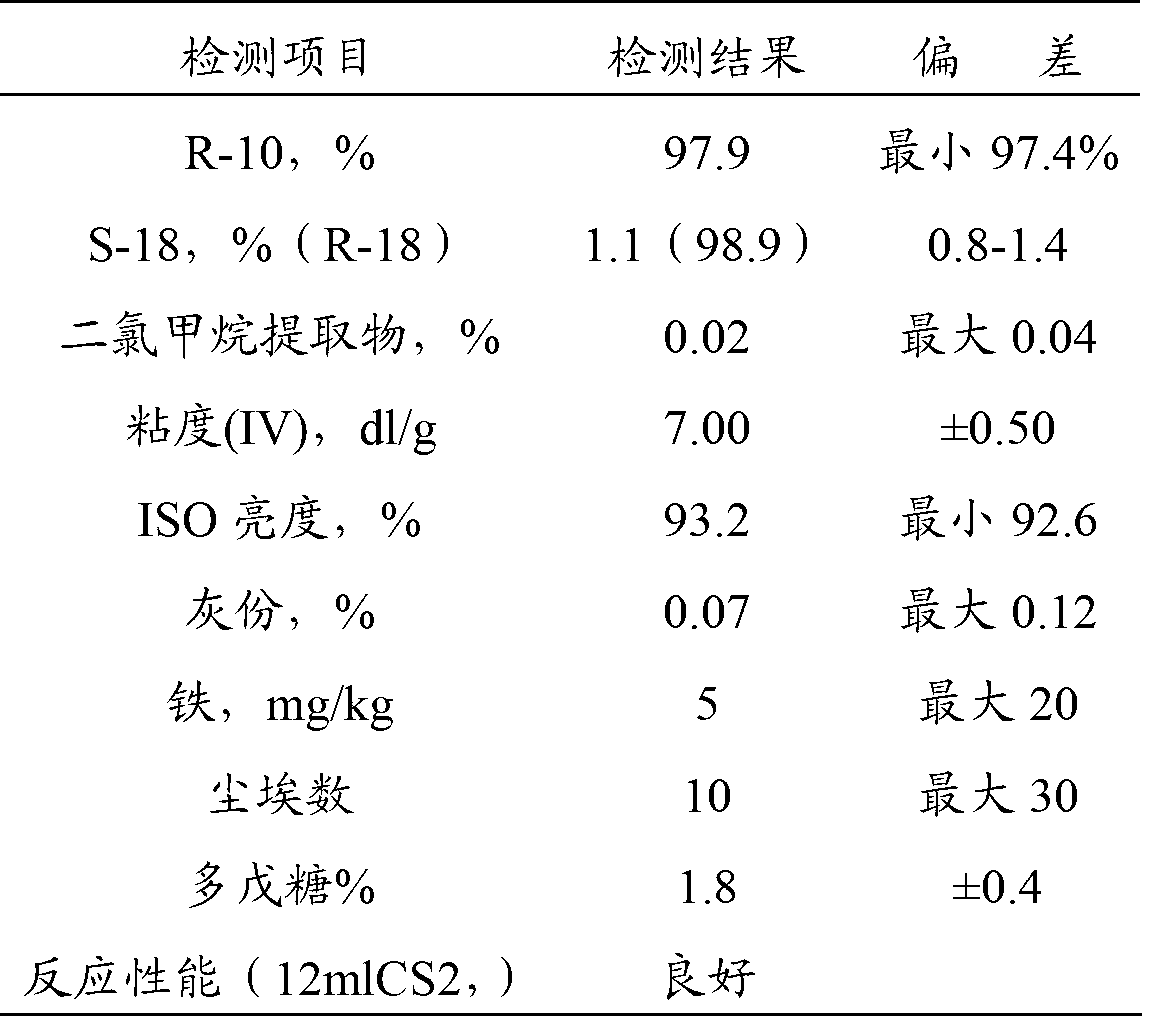

Image

Examples

preparation example Construction

[0042] The invention provides an esterification grade pulp and a preparation method thereof, comprising the following steps:

[0043] impregnating the cellulose raw material in a composition of one or more of biological enzymes, sodium sulfite and sodium bisulfite;

[0044] Perform steam pre-hydrolysis on the impregnated cellulose raw material to obtain a pre-hydrolyzed product, the temperature of the steam pre-hydrolysis is 100°C to 200°C, the pressure of the steam pre-hydrolysis is 0 MPa to 1.46 MPa, and the time of the steam pre-hydrolysis 60min~230min;

[0045] The pre-hydrolyzate is subjected to kraft cooking to obtain the cooked slurry. The amount of alkali used for the kraft-cooking Chinese medicine is 4% to 30% of the absolute dry mass of the pre-hydrolyzate, and the kraft-cooking Chinese medicine is The degree of sulfidation is 0-40%, the liquid ratio of the kraft cooking is 1: (3-10), the temperature of the kraft cooking is 80°C-200°C, and the time for heating to th...

Embodiment 1

[0069] 1) Preparation: Cut the bamboo into small bamboo sections with a length of 2cm, a width of 0.5cm, and a thickness of 1cm, and then place the obtained small bamboo sections in a mixture of white rot fungi, sodium sulfite and sodium bisulfite for 24 hours, white rot fungi and sodium sulfite The total mass of bamboo accounts for 1% of the absolute dry mass of small bamboo segments, the impregnation temperature is 15°C-25°C, and the liquid ratio is 1:1;

[0070] 2) Steam pre-hydrolysis: put the impregnated small bamboo segments in a cooking pot, then raise the temperature to 130°C under the pressure of 0.5±0.2MPa, keep it at this temperature for 230min, and the hydrolysis yield is 50%-95% %;

[0071] 3) Kraft cooking: the amount of alkali used for sulfate cooking is 20% of the absolute dry mass of the hydrolyzate obtained by pre-hydrolysis, the degree of sulfidation is 20%, and the liquid ratio is 1:4. The hydrolyzate obtained by pre-hydrolysis and sulfate Place the boiled...

Embodiment 2

[0083] Adopt the technical scheme of embodiment 1 to prepare vinegar grade pulp, different from embodiment 1, the raw material that adopts in the present embodiment is long 50mm, wide 3mm, thick 30mm eucalyptus wood chips, the time of immersion is 2h, the impregnated The temperature is 90°C, and the liquid ratio is 1:5;

[0084] During the steam prehydrolysis process, the pressure is 0.46MPa, the temperature is 130°C, and the holding time is 230min;

[0085] During the sulfate cooking process, the amount of alkali used is 30%, the degree of sulfidation is 40%, the liquid ratio is 1:30, the temperature is raised to 200°C in 200 minutes, the pressure is 8MPa, and the holding time is 20 minutes;

[0086] In the process of decompression, screening and washing, the decompression time is 50min, the inlet pressure of screening is 500kpa, the pressure difference is 200kpa, and the inlet pressure of washing is 2kpa;

[0087] During the bleaching process, the mass concentration of NaOH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com