Nanostructured lipid carrier for composite skin lightener and preparation method of composite skin lightener

A technology of nanostructured lipids and complex lipids, which can be used in food preparation, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of easy degradation and discoloration, poor water solubility, rough skin feeling, etc., so as to solubilize drugs and reduce viscosity. , The effect of improving light stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of Example 1 Composite Whitening Agent Nanostructured Lipid Carrier

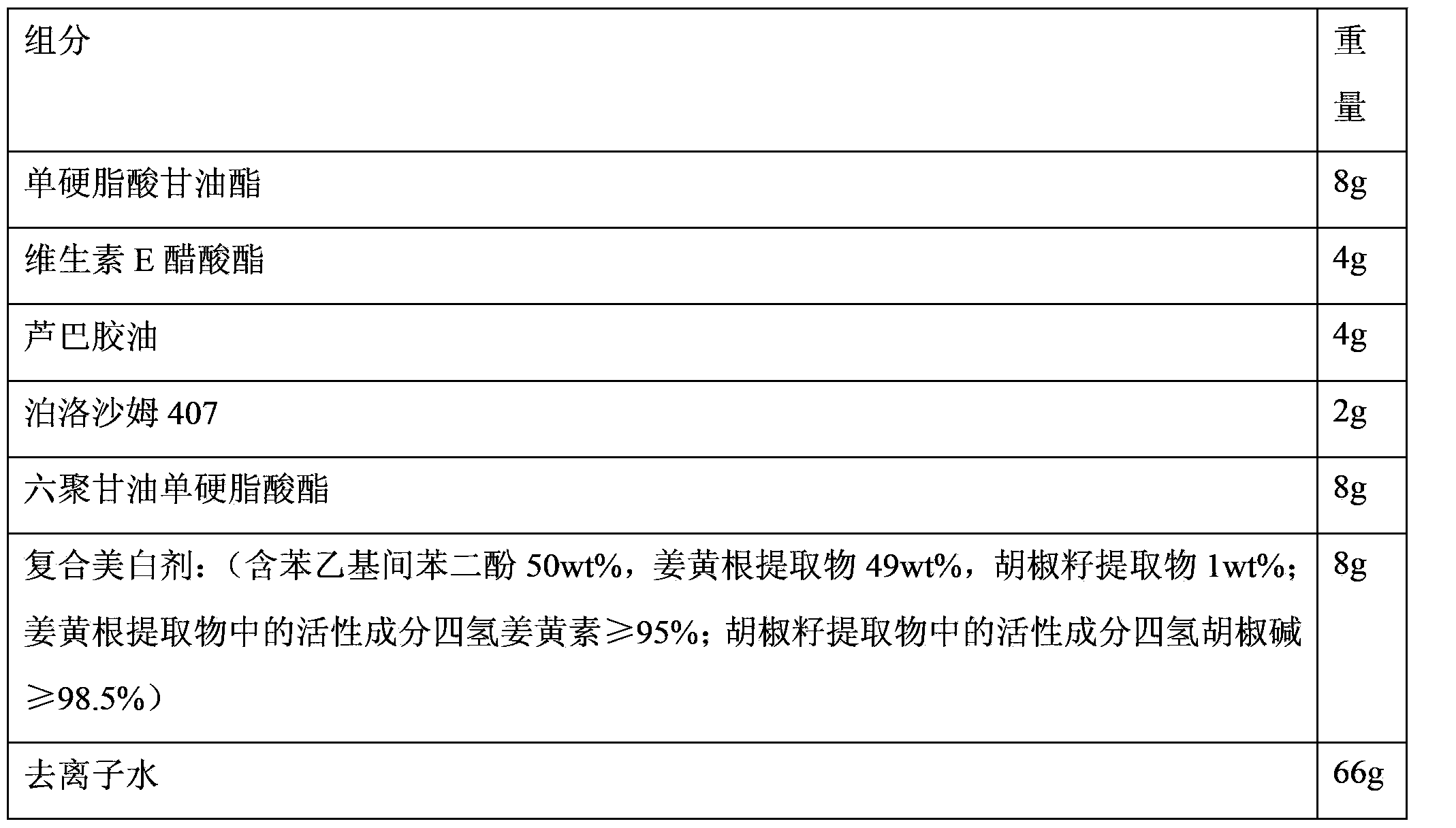

[0041] Composition formula

[0042]

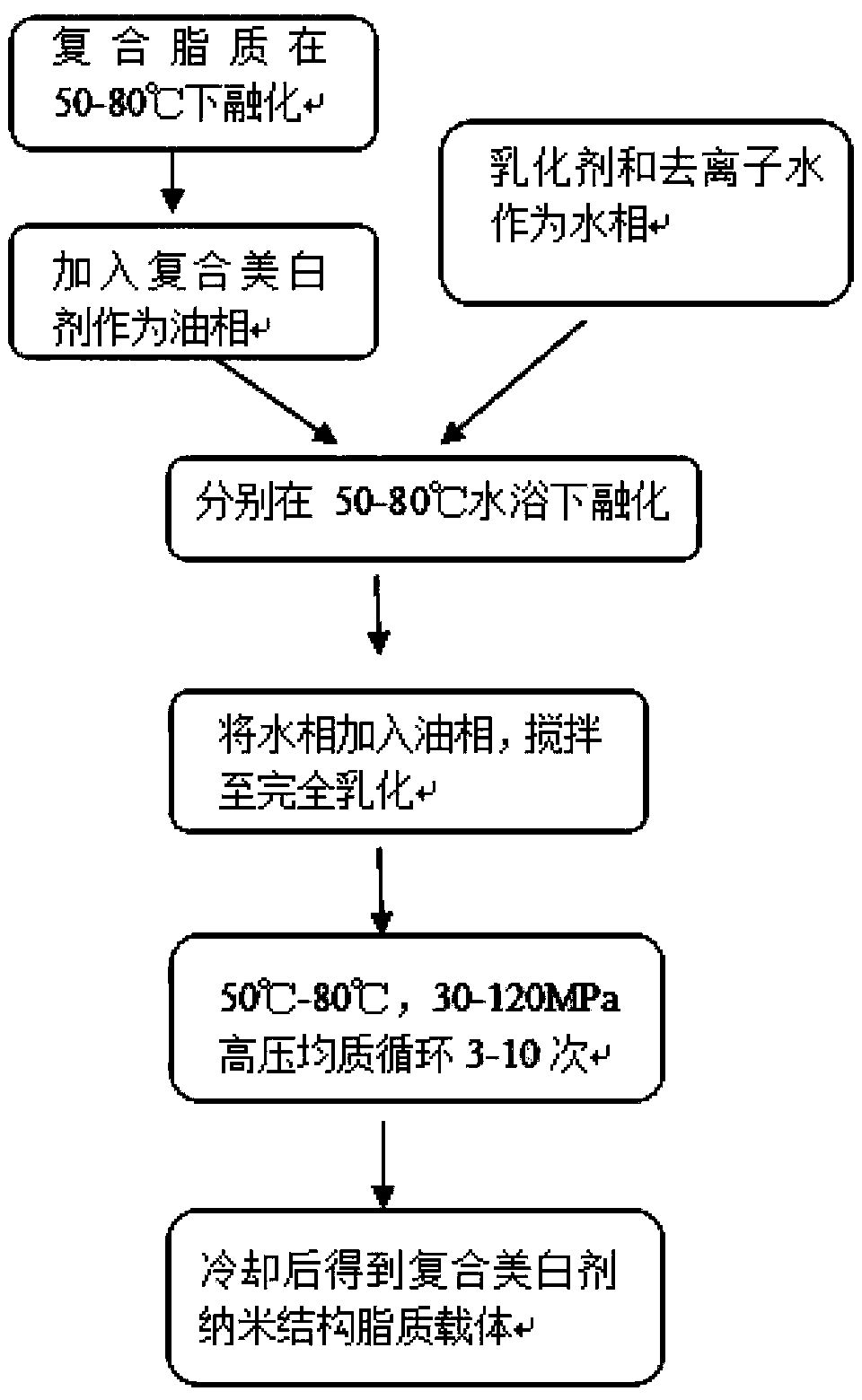

[0043] Such as figure 1 Shown, the preparation steps of this embodiment are as follows:

[0044] 1. Weigh 8g of glyceryl monostearate, 4g of vitamin E acetate, and 4g of ruba gum oil, weigh them, put them into a 150mL beaker, put them in a water bath at 65°C and stir at 340r / min until they melt, and use them as the oil phase; At the same time, turn on the high-pressure homogenizer and preheat it with 65°C deionized water;

[0045] 2. Weigh 4072g of poloxamer, 8g of hexaglyceryl monostearate, and 66g of deionized water, put them into a 100mL conical flask with a stopper, and place them in a water bath at 65°C as the water phase;

[0046] 3. Weigh 8g of compound whitening agent and add it to the melted oil phase, stir at 340r / min until completely melted;

[0047] 4. Pour the water phase into the oil phase at one time, and stir at 600r / min until co...

Embodiment 2

[0050] Preparation of Example 2 Composite Whitening Agent Nanostructured Lipid Carrier

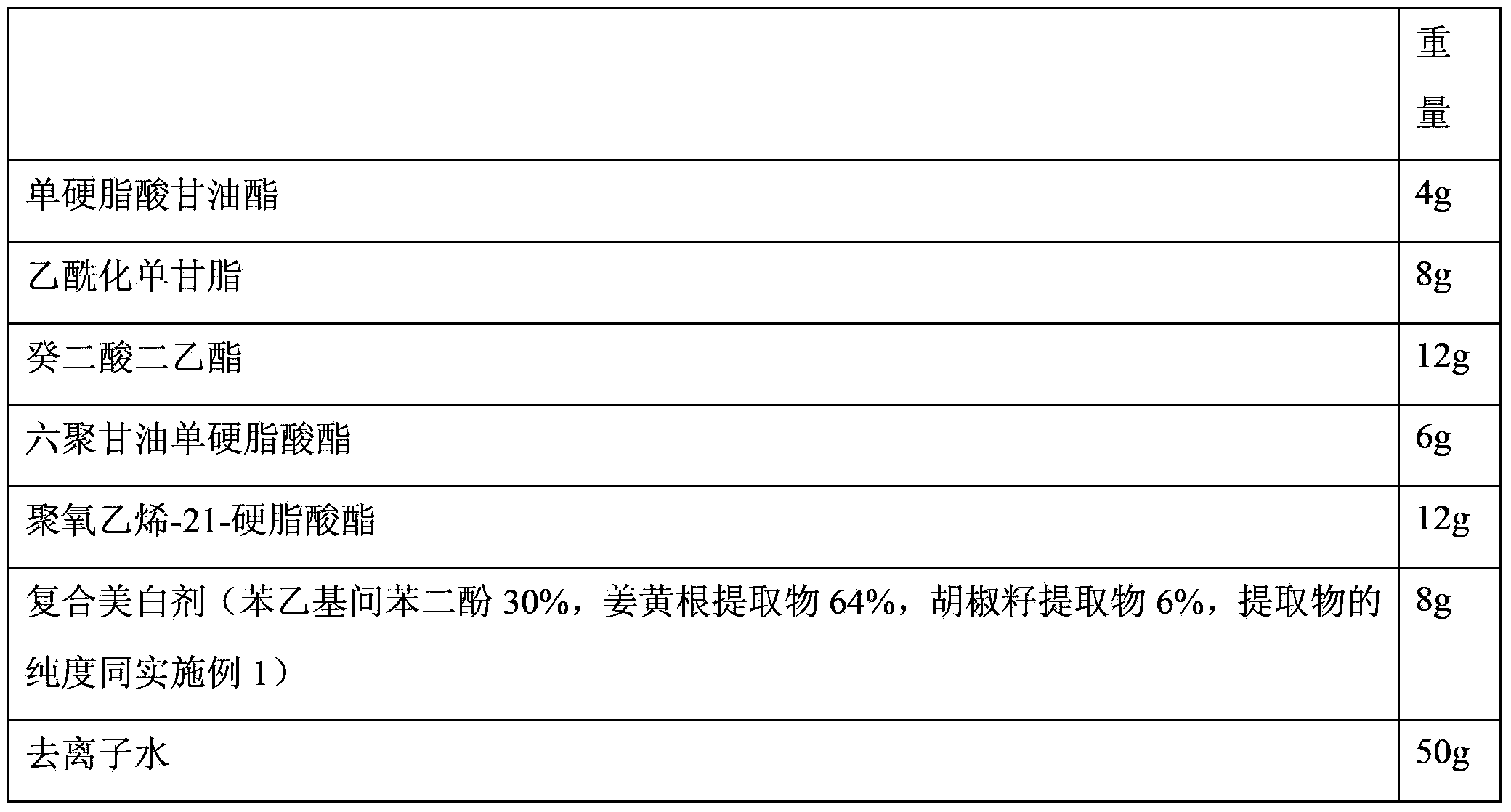

[0051] Composition formula

[0052]

[0053] Such as figure 1 Shown, the preparation steps of this embodiment are as follows:

[0054] 1. Weigh 4g of glyceryl monostearate, 8g of acetylated monoglyceride, 12g of diethyl sebacate, and 6g of hexaglyceryl monostearate, weigh them and put them in a 150mL beaker at 70°C Stir in a water bath at 350r / min until it melts, and use it as the oil phase; at the same time, turn on the high-pressure homogenizer and preheat it with 70°C deionized water;

[0055] 2. Weigh 12g of polyoxyethylene-21-stearate and 50g of deionized water, put it into a 100mL conical flask with a stopper, and place it in a 70°C water bath as the water phase;

[0056] 3. Weigh 8g of compound whitening agent and add it to the melted oil phase, stir at 350r / min until completely melted;

[0057] 4. Pour the water phase into the oil phase at one time, and stir at 600r / min unti...

Embodiment 3

[0060] Example 3 Preparation of Composite Whitening Agent Nanostructured Lipid Carrier

[0061] Composition formula

[0062]

[0063] Such as figure 1 Shown, the preparation steps of this embodiment are as follows:

[0064] 1. Weigh 4.67g of caprylic acid glyceride, 1.33g of vitamin E acetate, and 2g of luba gum oil, weigh them, put them into a 150mL beaker, put them in a water bath at 55°C and stir at 300r / min until they melt, and use them as the oil phase ; Simultaneously turn on the high-pressure homogenizer and preheat it with 55°C deionized water;

[0065] 2. Weigh 3g of O-1000, 2g of polyoxyethylene-700 stearate compound, and 83g of deionized water. After weighing, put it into a 100mL conical flask with a stopper, and place it in a water bath at 55°C as the water phase;

[0066] 3. Weigh 4g of compound whitening agent and add it to the melted oil phase, stir at 340r / min until completely melted.

[0067] 4. Pour the water phase into the oil phase at one time, and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com