Oxygen-containing coalbed methane carbon dioxide reforming synthesis gas catalyst and preparation method thereof

A carbon dioxide and catalyst technology, applied in the field of carbon dioxide reforming of oxygen-containing coalbed methane to syngas catalyst and its preparation, can solve the problems of pollution, waste of oxygen-containing coalbed methane, etc., achieve reasonable material ratio, improve service life, and accurate data Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

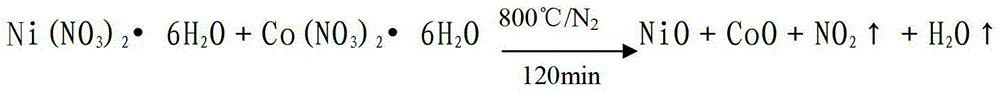

[0030] Example 1 Sol-gel Preparation of Oxygenated Coal Bed Gas Carbon Dioxide Reforming to Syngas Catalyst

[0031] Raw materials: First, according to the ratio of the mass of nickel nitrate: the mass of cobalt nitrate: the volume of distilled water is 4.20 ± 0.01g: 1.4 ± 0.010g: 60ml, add nickel nitrate and cobalt nitrate into distilled water respectively to make 30ml Then add the nitrate solution into the pseudo-boehmite hydrosol, add deionized water to 150ml, heat at 90°C and stir for 6h, and form a colloid, put the colloid in a constant temperature oven and dry it at 50°C for 200 hours, then put it in In a vacuum drying oven, evacuate to -0.08MPa, and dry at 90°C for 100 hours to form a solid-phase xerogel, grind the xerogel into powder, and then compress and mold it on a tablet machine at 20MPa to obtain a catalyst precursor , put the catalyst precursor into the quartz boat, and then put the quartz boat into the tube furnace. The temperature in the tube furnace rises fr...

Embodiment 2

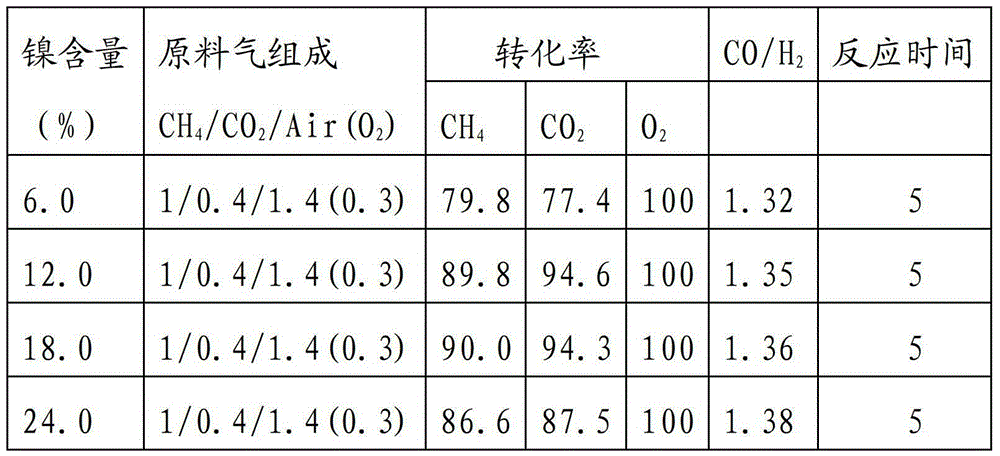

[0037] Example 2 Catalysts for carbon dioxide reforming of oxygen-containing coalbed methane with different nickel contents to synthesis gas

[0038] Catalyst preparation: according to the method of example 1, the nickel nitrate weighing amount is respectively 1.40g ± 0.01g, 2.80g ± 0.01g, 4.20g ± 0.01g, 5.60g ± 0.01g, and different Ni contents are 6%, 12 %, 18%, 24% of oxygen-containing coal bed methane carbon dioxide reforming synthesis gas catalyst.

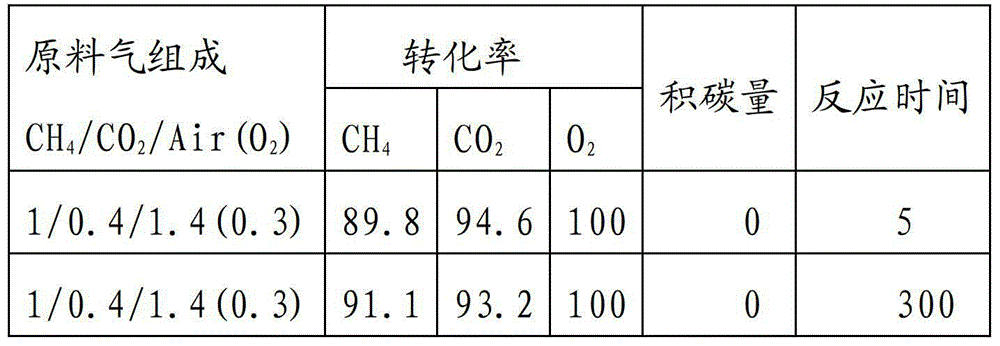

[0039] Evaluation conditions

[0040] with 20%H 2 / N 2 The mixed gas is reduced for 40 minutes, and the total space velocity of the raw gas is 28400cm 3 g -1 h -1 、CH 4 / CO 2 / Air(O 2 ) under the condition that the molar ratio is 1 / 0.4 / 1.4 (0.3), the reaction temperature is 800°C and normal pressure. The evaluation results are shown in Table 2

[0041] Table 2. Reaction performance of catalysts for carbon dioxide reforming of oxygen-containing coalbed methane to synthesis gas with different nickel contents

[0042] ...

Embodiment 3

[0044] Example 3 Catalysts for producing synthesis gas from carbon dioxide reforming of oxygen-containing coalbed methane at different calcination temperatures

[0045] Catalyst preparation: According to the method of Example 1, the calcination temperatures were 600, 700, 800 and 900° C. to prepare synthesis gas catalysts for carbon dioxide reforming of oxygen-containing coalbed methane at different calcination temperatures.

[0046] Evaluation conditions

[0047] with 20%H 2 / N 2 The mixed gas is reduced for 40 minutes, and the total space velocity of the raw gas is 28400cm 3 g -1 h -1 、CH 4 / CO 2 / Air(O 2 ) under the condition that the molar ratio is 1 / 0.4 / 1.4 (0.3), the reaction temperature is 800°C and normal pressure. The evaluation results are shown in Table 3.

[0048] Table 3. Reaction performance of catalysts for carbon dioxide reforming of oxygen-containing coalbed methane to synthesis gas at different calcination temperatures

[0049]

[0050] This exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com