Novel polyoxometallate polymer and preparation method thereof

A polyoxometalate and polymer technology, which is applied in the fields of organic, polymer chemistry, inorganic and material chemistry, can solve the problems that polyoxometallate polymers have not been reported, and facilitate industrial production and popularization and application. Simple synthesis process and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

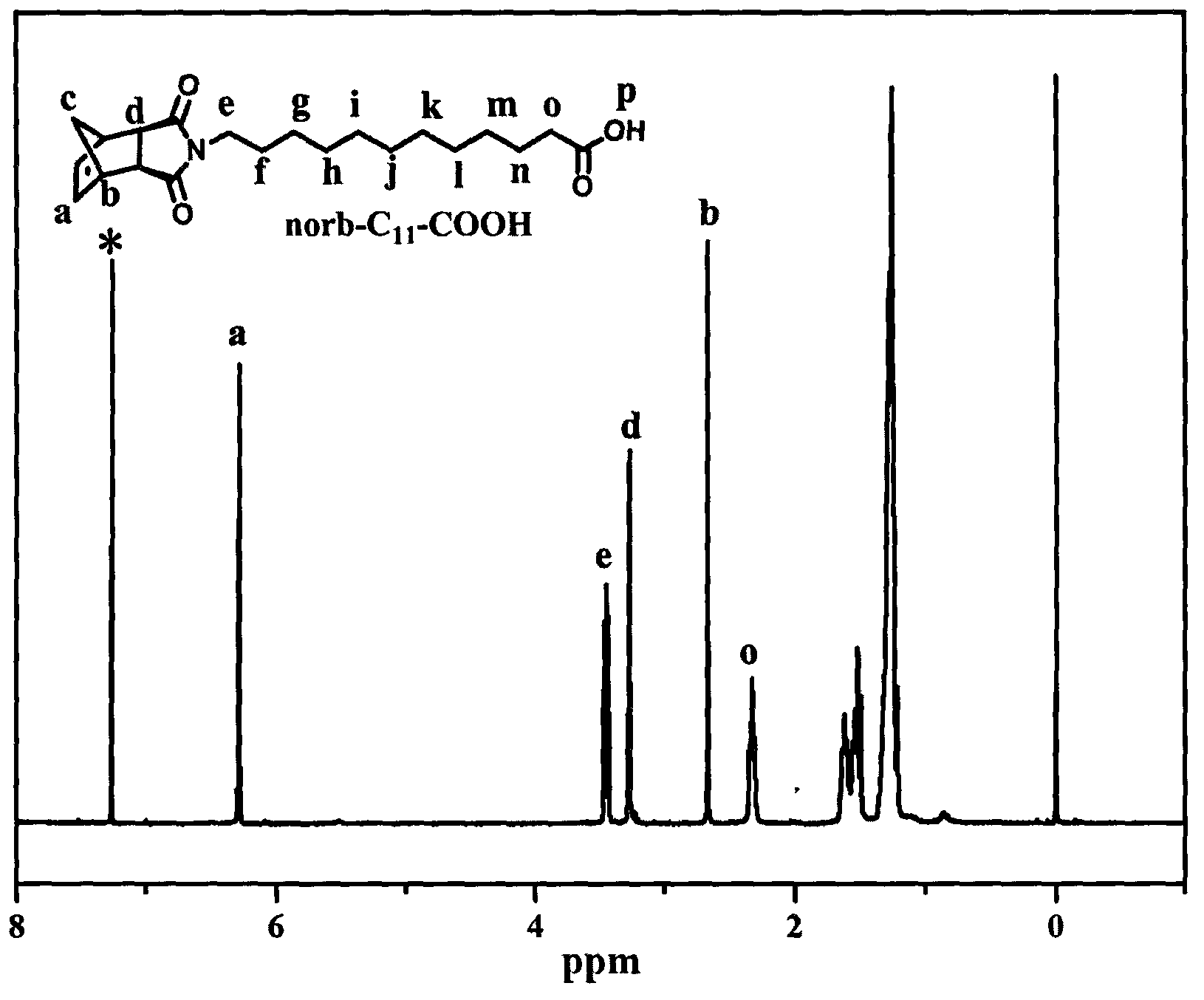

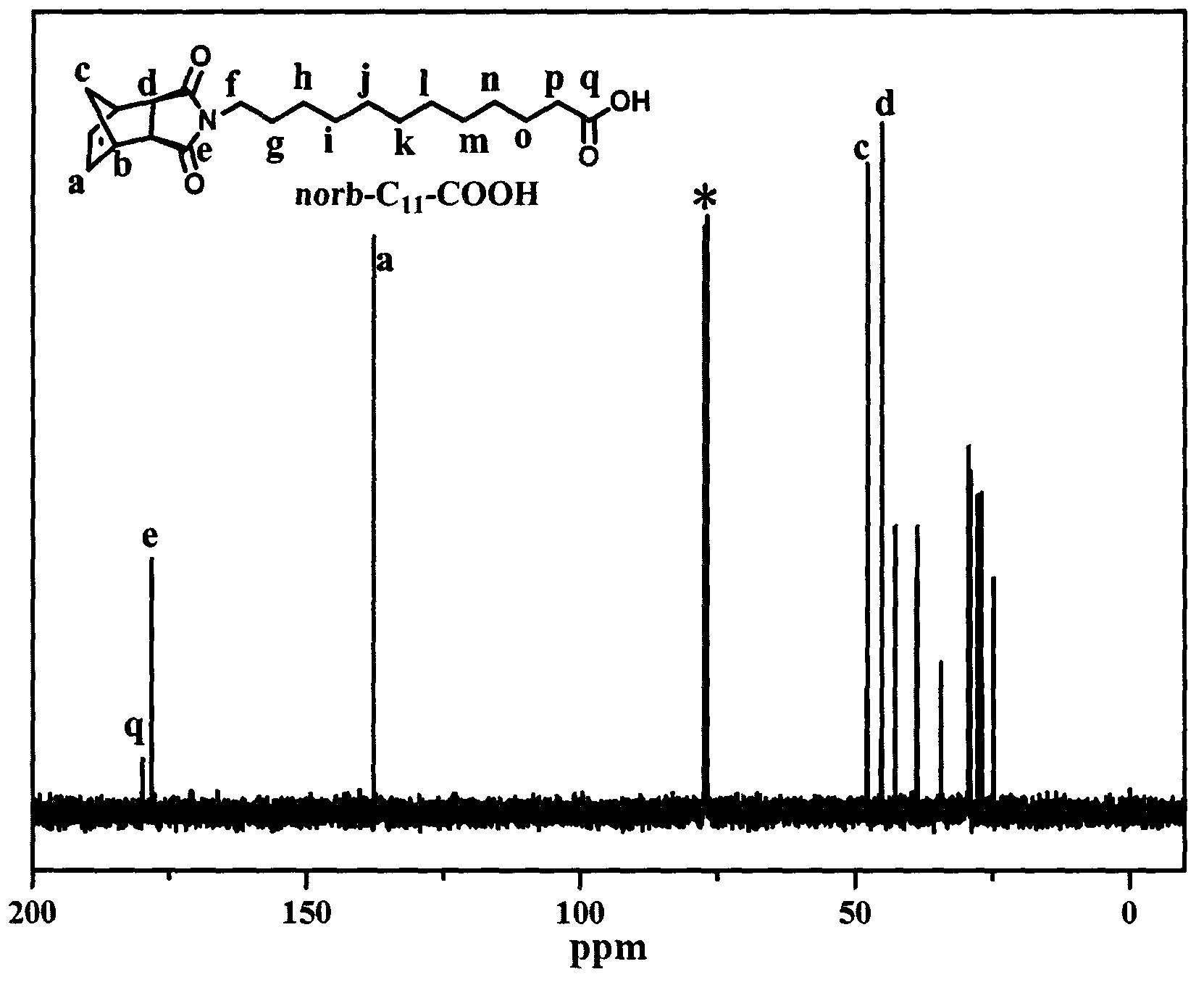

[0033] Embodiment 1: N-dodecanoic acid-cis-5-norbornene-external-2,3-dicarboximide (norb-C 11 -COOH) synthesis

[0034] In a 25ml single-necked round bottom flask equipped with a water trap, add 164mg (1mmol) of cis-5-norbornene-exo-2,3-dicarboxylic anhydride, 237mg (1.1mmol) of 12-amino-dodecanoic acid Acid, 10ml toluene, reflux for 20h, stop the reaction. It was dissolved in 20 ml of ethyl acetate, washed three times with distilled water and saturated brine, dried over anhydrous sodium sulfate, filtered, spin-dried, and recrystallized from ethyl acetate to obtain 343 mg (0.95 mmol) of a white solid, with a yield of 95%.

Embodiment 2

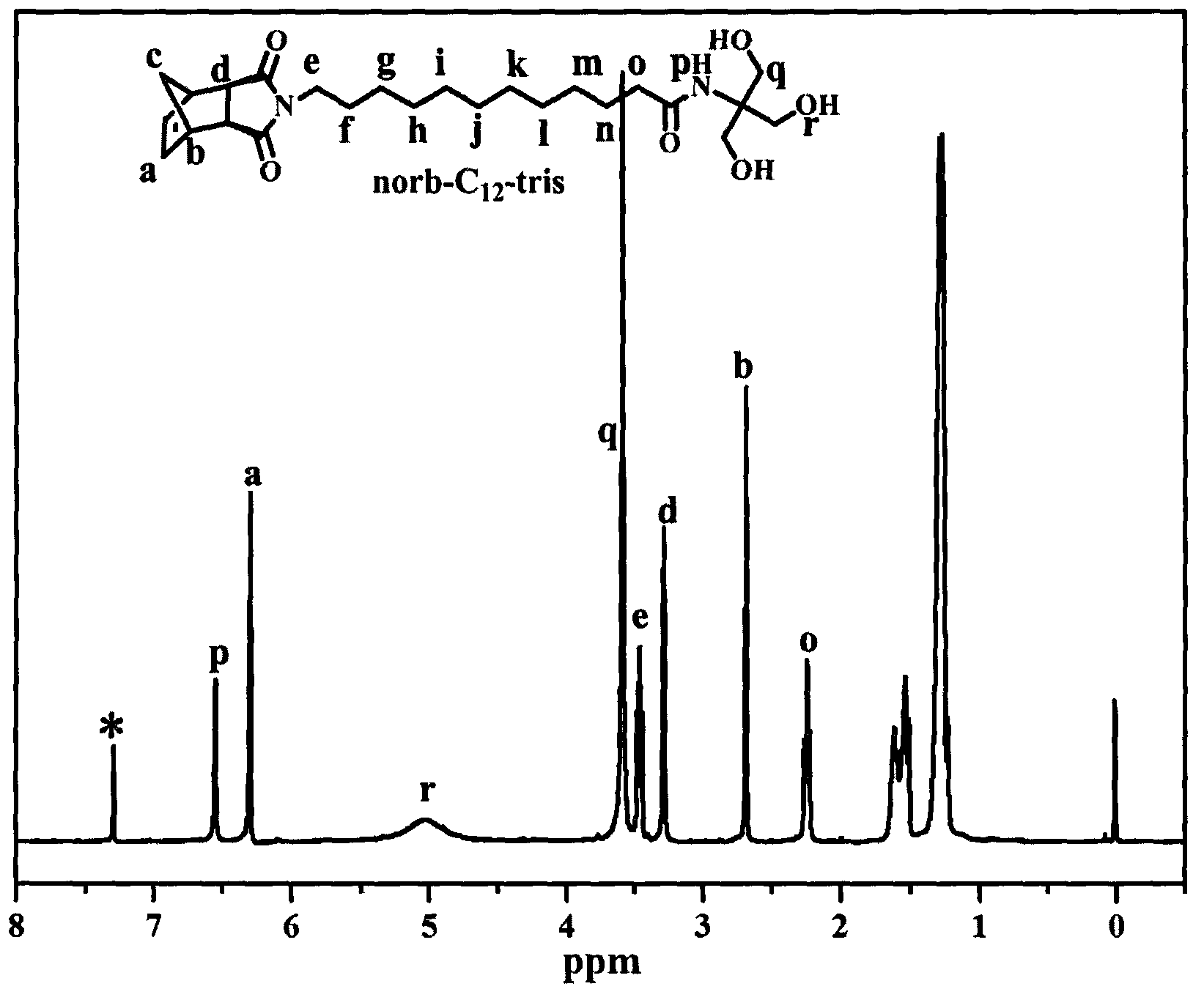

[0035] Example 2: N-12-[tris(hydroxymethyl)methylamino]-dodecamide-cis-5-norbornene-external-2,3-dicarboximide (norb-C12-tris )Synthesis

[0036] In a 100ml single-necked round bottom flask, 1.09g (3.02mmol) of N-dodecanoic acid-cis-5-norbornene-exo-2,3-dicarboximide, 0.44g (3.63mmol) of trihydroxy Methylaminomethane, 1.12g (4.53mmol) was dissolved in 50ml of absolute ethanol, and refluxed for 12h. Spin dry, dissolve dichloromethane, filter to remove excess trishydroxymethylaminomethane, use 20:1 (v / v) dichloromethane:methanol as eluent, and pass through silica gel (100-200 mesh) column chromatography 998 mg (2.15 mmol) of the target compound were isolated with a yield of 71%.

Embodiment 3

[0037] Example 3: norbornenylated polyoxometalate hybrids (norb-C 12 -POM) synthesis

[0038] In a 50ml single-necked round bottom flask, add 46mg (0.098mmol) N-12-[tris(hydroxymethyl)methylamino]-dodecamide-cis-5-norbornene-exo-2,3-dimethyl imide, 484 mg (0.089 mmol) [(n-Bu) 4 N] 6 h 3 P 2 W 15 V 3 o 62 , 20ml of N,N-dimethylformamide, reacted at 85°C for 7 days. Concentrate, precipitate with ether, and centrifuge to obtain 510 mg of a yellow solid with a yield of 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com