Al-Sn film negative electrode and preparation method thereof

An al-sn and thin-film technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of irregular distribution of Al and Sn, small diffusion rate, etc., achieve structural stability improvement, good flexibility, and ease volume expansion effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

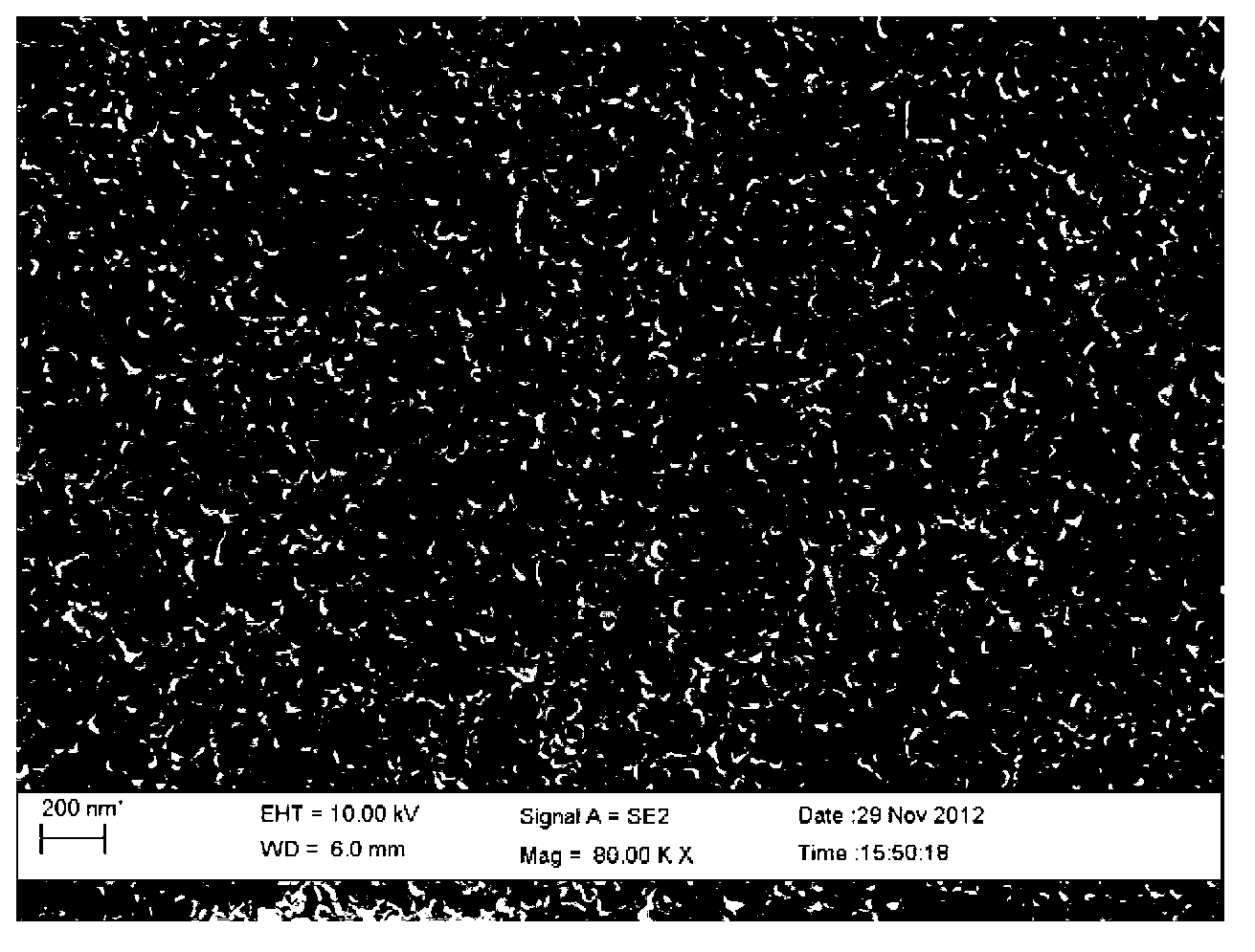

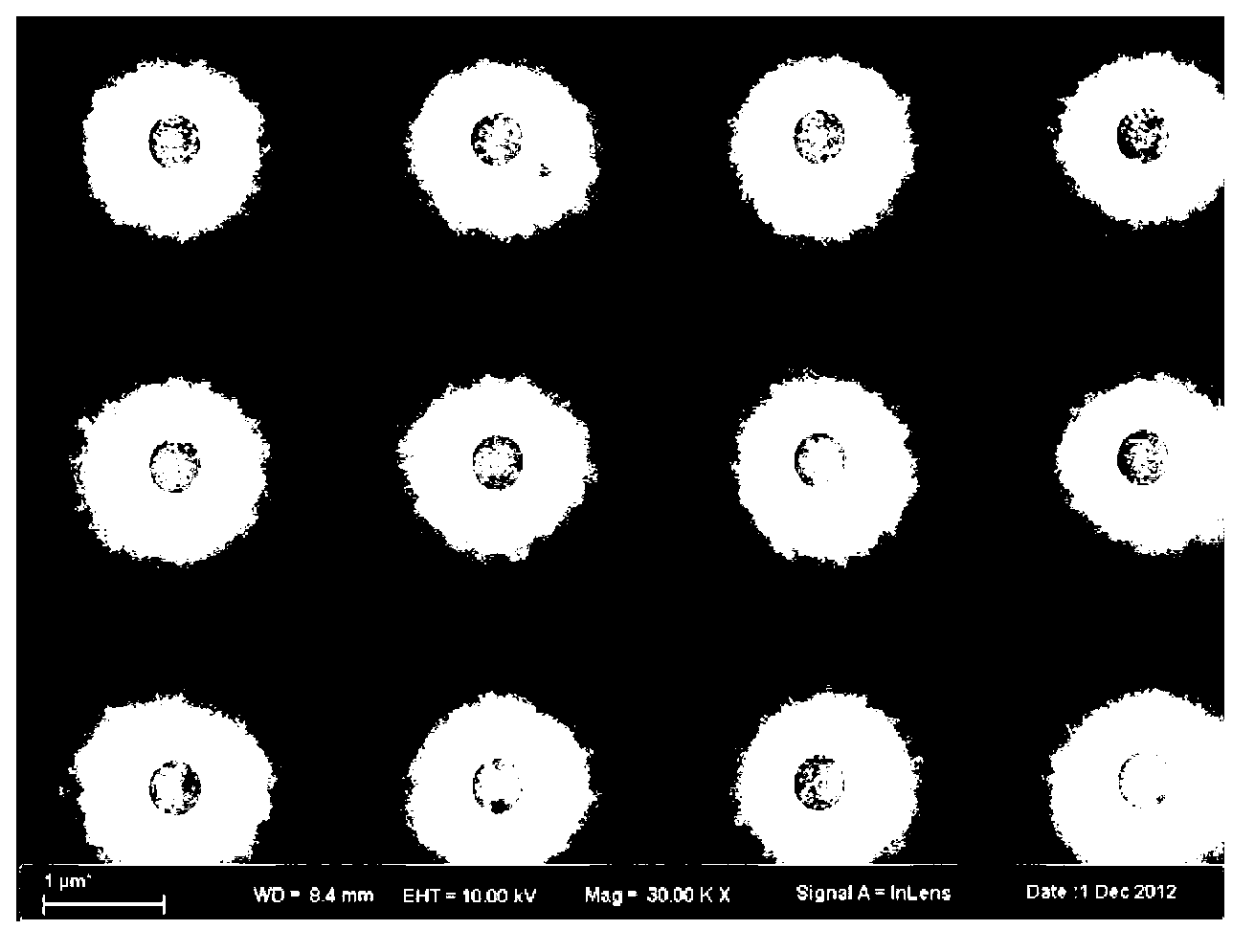

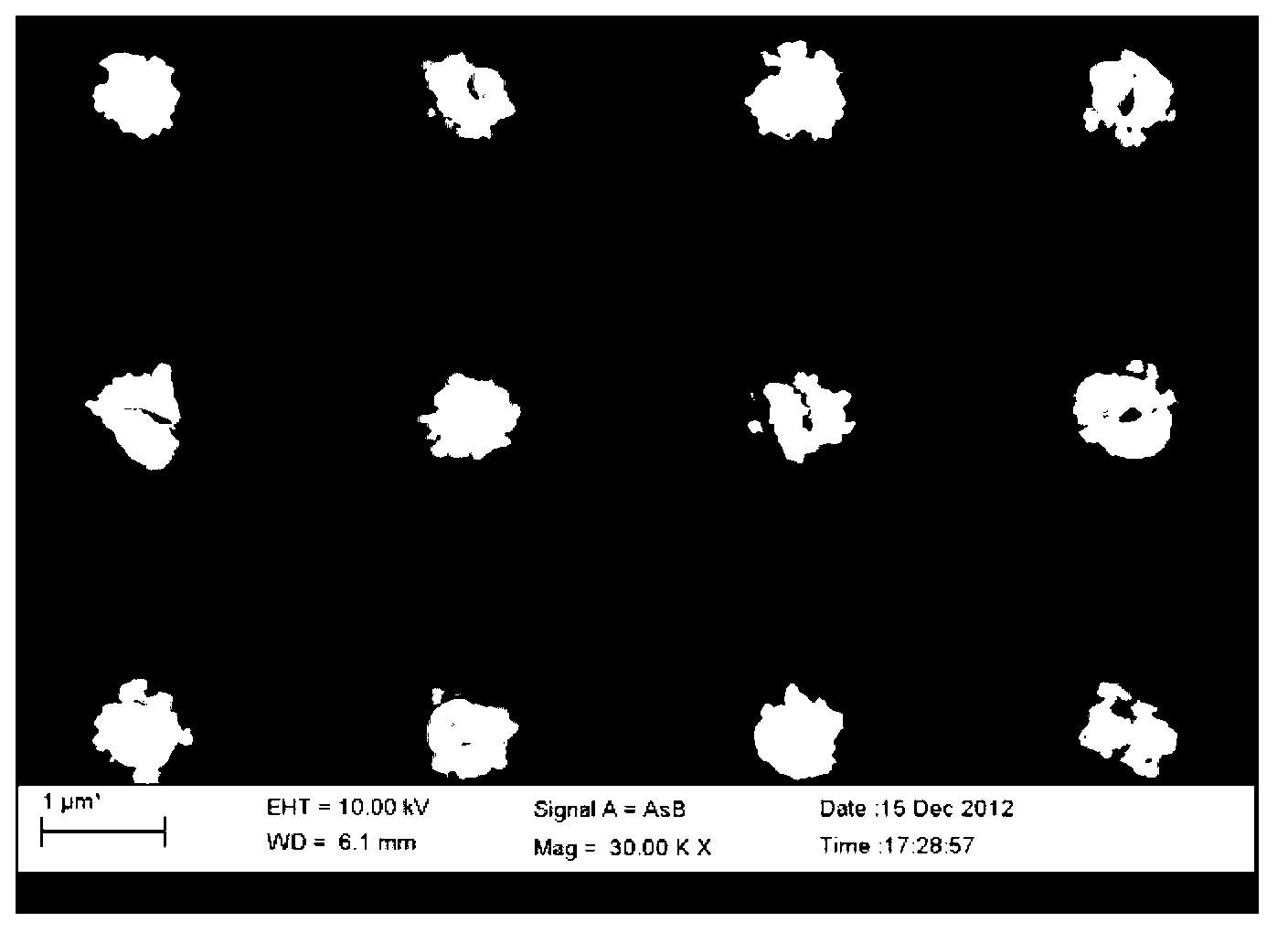

[0033] According to the microstructure of the invented Al-Sn thin film electrode, according to the characteristics of mutual insolubility of Al and Sn, a regular array pattern is designed, and at the same time, the size of the Sn particles obtained by the vacuum magnetron sputtering thin film deposition technology, and the Al , Sn composition ratio problem, the aperture size design in the array pattern is 500nm. In the whole experiment process, the brass sheet was used as the substrate, pure Al was selected as the target material, and the Al film was prepared by vacuum magnetron sputtering, the sputtering power was 100W, and the sputtering time was 20min. PMMA with a mass fraction of 4% and a molecular weight of 350K was selected as the electron beam resist, coated on the surface of the Al film with a coater, and patterned on the resist layer by electron beam exposure. Then use PMMA as a protective layer, select 25% tetramethylammonium hydroxide aqueous solution to etch Al, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com