Preparation method of acrylic polymer grafted carbon fiber multi-scale reinforcement

An acrylic and carbon fiber technology, which is applied in fiber processing, physical processing, textiles and papermaking, etc., can solve the problems that the mechanical properties of composite materials such as flexural strength and impact strength have not been effectively improved, and achieve less interface defects. Good performance, the effect of improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

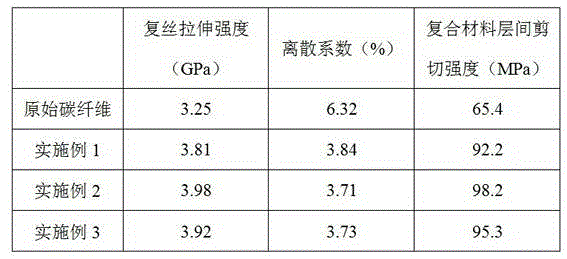

Examples

example 1

[0017] This example illustrates the preparation method of the acrylic polymer grafted carbon fiber multi-scale reinforcement provided by the present invention;

[0018] Step 1: Immerse 2g of carbon fiber in 60mL of concentrated nitric acid with a concentration of 68%, ultrasonically treat it for 8 hours, and then transfer it to an oil bath at 100°C for 3 hours of reflux reaction. Dry in a vacuum oven at 60°C for 24 hours to obtain nitric acid oxidation treated carbon fiber ;

[0019] Step 2: Oxidize 1g of nitric acid to treat carbon fiber Disperse in 50mL of toluene, add 15g of silane coupling agent (γ-aminopropyltriethoxysilane) after ultrasonic treatment for 20 minutes, then heat up to 120°C, reflux for 7 hours, cool and discharge, wash with toluene 3 times Remove ungrafted silane coupling agent. Vacuum drying at room temperature for 24 hours to obtain silane coupling agent grafted carbon fiber ;

[0020] Step 3: Graft 1g of silane coupling agent to carbon fiber at r...

example 2

[0023] This example illustrates the preparation method of the acrylic polymer grafted carbon fiber multi-scale reinforcement provided by the present invention;

[0024] The first step: immerse 2g of carbon fiber in 80mL of concentrated nitric acid with a concentration of 65%, ultrasonically treat it for 10 hours, and then transfer it to an oil bath at 110°C for 2 hours of reflux reaction. Dry in a vacuum oven at 60°C for 24 hours to obtain nitric acid oxidation treated carbon fiber ;

[0025] Step 2: Oxidize 1g of nitric acid to treat carbon fiber Disperse in 80mL of toluene, add 18g of silane coupling agent (γ-aminopropyltriethoxysilane) after ultrasonic treatment for 30 minutes, then heat up to 110°C, reflux for 5 hours, cool and discharge, wash with toluene 5 times Remove ungrafted silane coupling agent. Vacuum drying at room temperature for 24 hours to obtain silane coupling agent grafted carbon fiber ;

[0026] Step 3: Graft 1g of silane coupling agent to carbon f...

example 3

[0029] This example illustrates the preparation method of the acrylic polymer grafted carbon fiber multi-scale reinforcement provided by the present invention;

[0030] Step 1: Immerse 2g of carbon fiber in 100mL of concentrated nitric acid with a concentration of 67%, ultrasonically treat it for 6 hours, and then transfer it to an oil bath at 120°C for 4 hours of reflux reaction. Dry in a vacuum oven at 60°C for 24 hours to obtain nitric acid oxidation treated carbon fiber ;

[0031] Step 2: Oxidize 1g of nitric acid to treat carbon fiber Disperse in 40mL of toluene, add 20g of silane coupling agent (γ-aminopropyltriethoxysilane) after ultrasonic treatment for 60 minutes, then heat up to 100°C, reflux for 8 hours, cool and discharge, wash with toluene 4 times Remove ungrafted silane coupling agent. Vacuum drying at room temperature for 24 hours to obtain silane coupling agent grafted carbon fiber ;

[0032] Step 3: Graft 1g of silane coupling agent to carbon fiber at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com