Preparation method of pointed-cone-shaped zinc oxide/nickel oxide heterojunction diodes

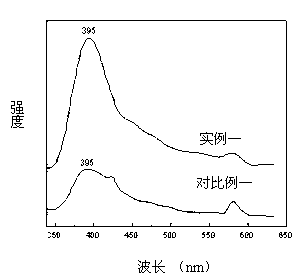

A zinc oxide, heterojunction technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of difficulty in preparing ZnO homojunction diodes, no stable preparation method, etc., and achieve the effect of high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

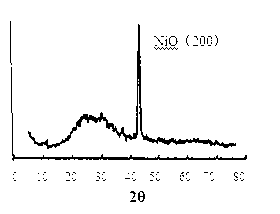

[0020] 1. Form a 200nm thick NiO layer on the nickel sheet by thermal oxidation

[0021] Put the nickel sheet with a pointed surface structure into a heating furnace and heat it in the air at a heating temperature of 450 o C, heating time 45 min.

[0022] 2. Using ALD technology to prepare 80nm thick ZnO

[0023] Deposition conditions: reaction temperature 200°C, Zn(CH 2 CH 3 ) 2 (DEZ) for 1 s, nitrogen purge for 1.5 s, water for 500 ms, nitrogen purge for 1 s, repeat the above process 800 times.

[0024] 3. Preparation of ITO transparent upper electrode by sputtering method

[0025] ITO target is used, argon is used as sputtering gas; firstly, the background vacuum of the chamber is evacuated to 1′10 -4 Pa, argon gas is introduced, the working pressure of argon gas is 1.5 Pa, the sputtering power is 60w, the sputtering time is 20min, and the electrode thickness is 100nm.

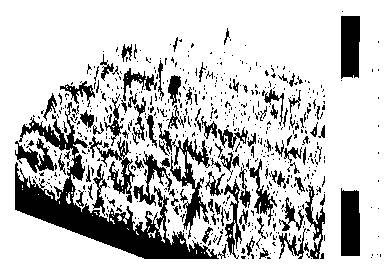

[0026] 4. Use femtosecond laser processing technology to form a pointed cone columnar structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com