Alcohol-based printing ink composition

A technology of printing ink and composition, which is applied in the field of alcohol-based printing ink composition, which can solve the problems of poor compatibility of binder resin and inability to ensure the dispersion stability of pigments, etc., and achieve the effect of excellent film physical properties and excellent storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

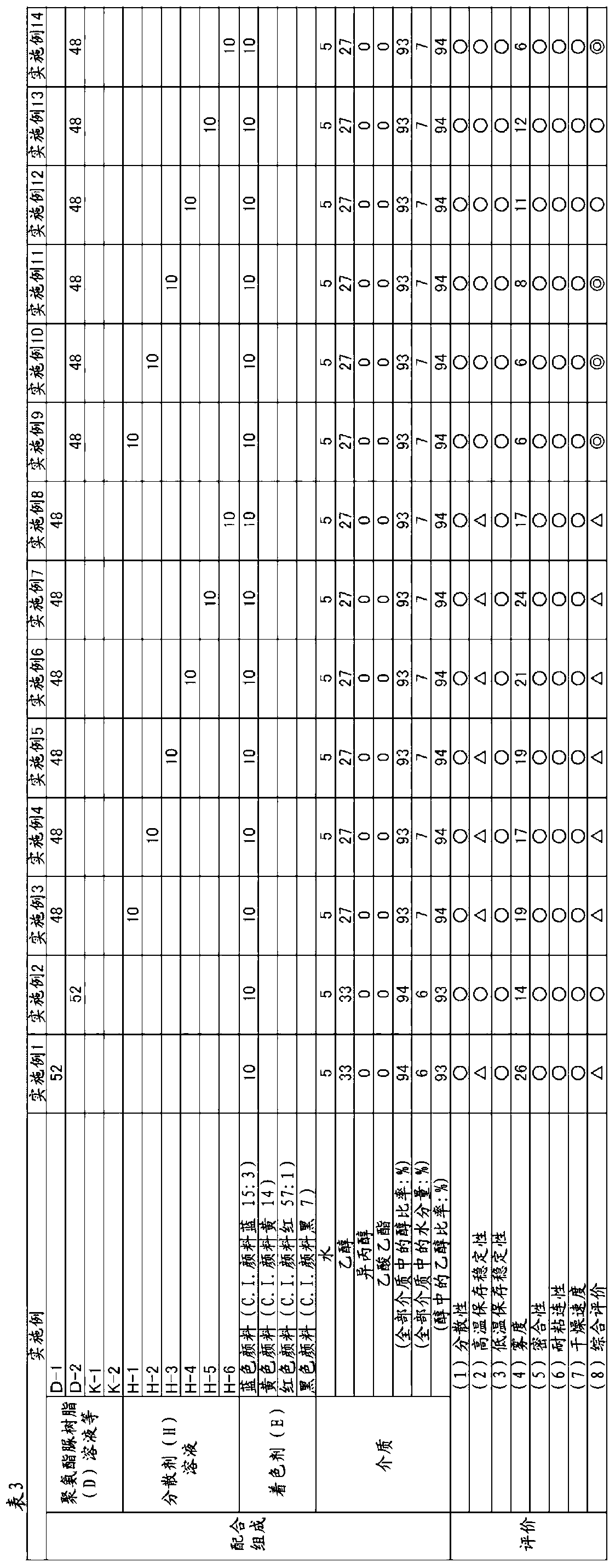

[0091] Hereinafter, the present invention will be further specifically described through examples, but the following examples do not limit the claims of the present invention in any way. Here, "parts" in the examples means "parts by weight", and "%" means "% by weight".

[0092] However, the measuring methods of "resin solid content concentration", "viscosity", "amine value", "weight average molecular weight" and "acid value" in Examples are as follows.

[0093] Resin solid content concentration: The heating residual content when measured at a heating temperature of 150° C. for a heating time of 20 minutes in accordance with JIS K5601-1-2 was defined as the resin solid content concentration (%).

[0094] Viscosity: Measured at 25°C with an E-type viscometer.

[0095] Amine value: Measure about 3 g of polyurethane urea resin solution in a flask, add 50 ml of methanol to dissolve, titrate with 0.1 mol / l hydrochloric acid standard solution by potentiometric titration, and calcul...

Synthetic example 1

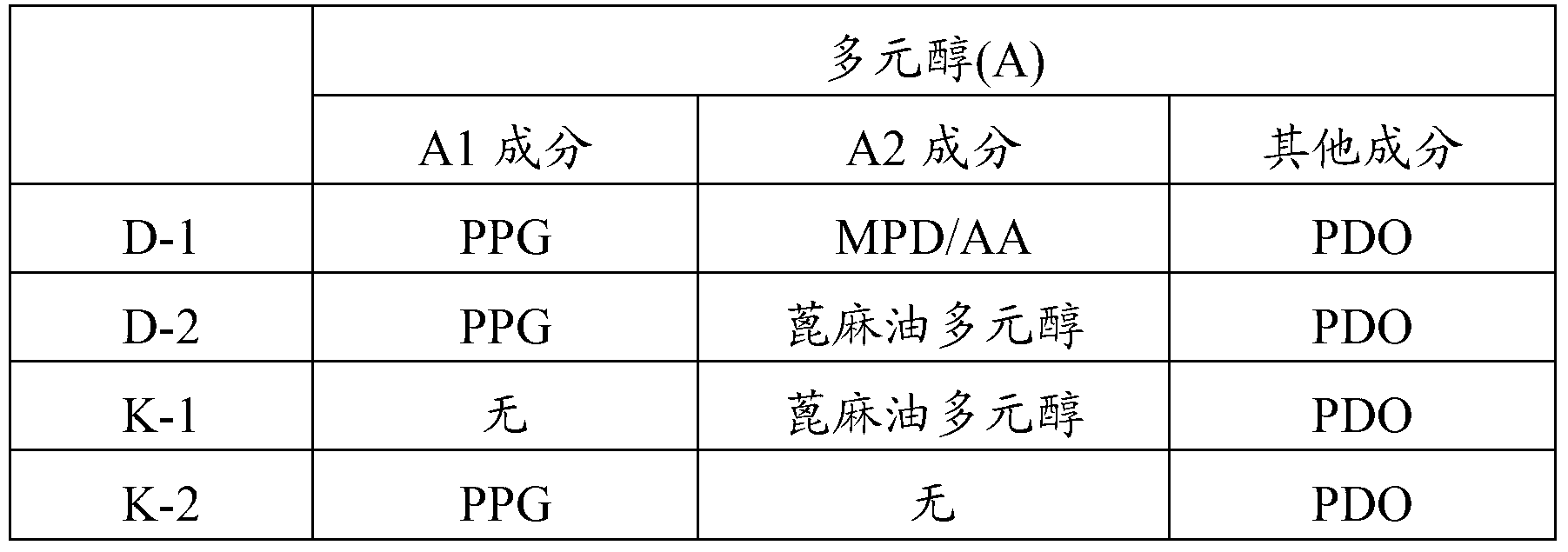

[0103] (Synthesis example 1)

[0104] In a flask equipped with a stirrer, a thermometer, a reflux condenser, and a nitrogen inlet tube, add 33.5 parts of a polycondensate of adipic acid and 3-methyl-1,5-pentanediol (hydroxyl value: 56.1 mg KOH / g, number average Molecular weight 2000), 33.5 parts of polypropylene glycol (hydroxyl value 56.1mg KOH / g, number average molecular weight 2000), 4.6 parts of 1,3-propanediol and 41.6 parts of isophorone diisocyanate were reacted at 90°C under nitrogen flow for 6 hours, to manufacture polyurethane prepolymers. Then, 48.5 parts of tert-butanol were added to the obtained polyurethane prepolymer to prepare a uniform solution of the polyurethane prepolymer. Then, in a mixture composed of 17.2 parts of isophorone diamine and 342.4 parts of ethanol, the above-mentioned polyurethane prepolymer solution was added dropwise for 1 hour, followed by reaction for 1 hour, thereby obtaining polyurethane urea resin (D-1) The solution. Regarding the ...

Synthetic example 2

[0105] (Synthesis example 2)

[0106] 40.5 parts of castor oil polyol (product name: "URIC H1824" manufactured by Ito Oil Co., Ltd., hydroxyl value 71.2 mg KOH / g, average number of functional groups 2 , number average molecular weight 1576), 27.0 parts of polypropylene glycol (hydroxyl value 56.1mg KOH / g, number average molecular weight 2000), 4.1 parts of 1,3-propanediol and 41.6 parts of isophorone diisocyanate, under nitrogen flow, at 90 °C for 6 hours to produce a polyurethane prepolymer. Then, 48.5 parts of tert-butanol were added to the obtained polyurethane prepolymer to prepare a uniform solution of the polyurethane prepolymer. Then, in a mixture composed of 17.4 parts of isophorone diamine and 343.0 parts of ethanol, the above-mentioned polyurethane prepolymer solution was added dropwise for 1 hour, followed by reaction for 1 hour, thereby obtaining polyurethane urea resin (D-2) The solution. Regarding the obtained solution of polyurethane urea resin (D-2), the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com