Dietary fiber extracted from Chinese yew, extraction method and use

A technology of dietary fiber and yew, which is applied in the field of extraction and dietary fiber, can solve the problems of long time consumption, pollution yield, and low yield, and achieve the effect of increasing yield, no chemical residue, and simple and easy production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

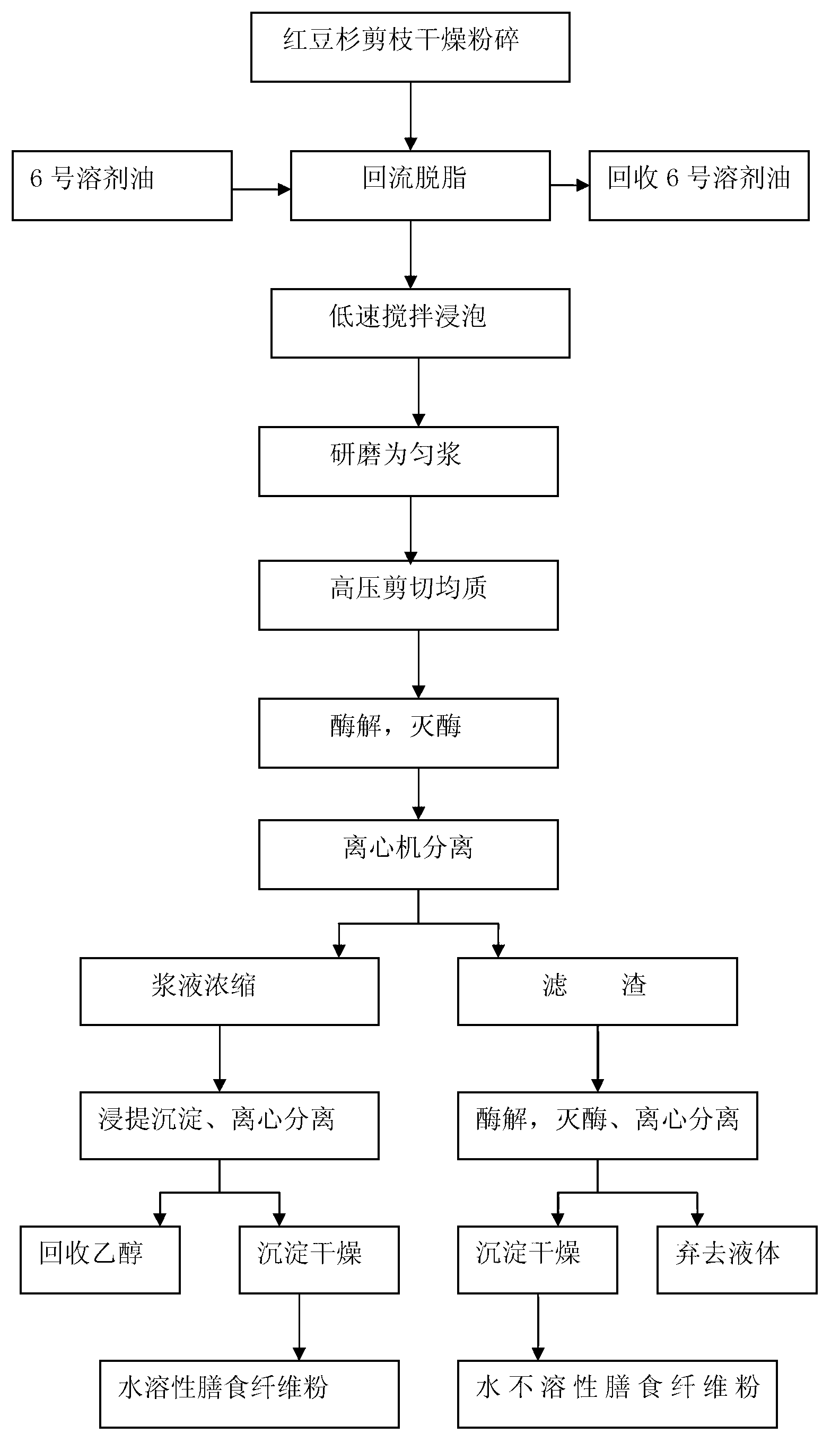

Method used

Image

Examples

Embodiment 1

[0071] (1) Chop the yew branches, dry, crush, and pass through a 80-mesh sieve. The sieve is ready for use.

[0072] (2) Weigh 10 kg of the undersize, put it in a reflux extraction tank, add 2 times by mass of No. 6 solvent oil, and reflux for 2 hours to degrease.

[0073] (3) Suction filtration, recover No. 6 solvent oil, air-dry the filter residue, and set aside.

[0074] (4) Take the filter residue, place it in a heating and stirring tank, add 10 times the mass of water, stir and soak at a low speed at 50°C for 30 minutes. Make the yew powder residue fully absorb water to form a slurry.

[0075] (5) Pour the slurry prepared in (4) into the colloid mill in batches, and grind for 5 minutes in a circular manner. Grind the slurry to a homogenate.

[0076] (6) Pour the slurry prepared in (5) into a high-pressure homogenizer, perform high-pressure shear homogenization, twice, and the pressure is 800 bar.

[0077] (7) Put the homogenized slurry into a stirring tank, add 0.5% ...

Embodiment 2

[0082] (1) Chop the yew branches, dry, crush, and pass through a 80-mesh sieve. The sieve is ready for use.

[0083] (2) Weigh 10 kg of the undersize, put it in a reflux extraction tank, add 10 times the amount of No. 6 solvent oil, and reflux for 2 hours to degrease.

[0084] (3) Suction filtration, recover No. 6 solvent oil, air-dry the filter residue, and set aside.

[0085] (4) Take the filter residue, place it in a heating and stirring tank, add 5 times the mass of water, stir and soak at a low speed at 70°C for 30 minutes. Make the yew powder residue fully absorb water to form a slurry.

[0086] (5) Pour the slurry prepared in (4) into the colloid mill in batches, and grind for 5 minutes in a circular manner. Grind the slurry to a homogenate.

[0087] (6) Pour the slurry prepared in (5) into a high-pressure homogenizer, perform high-pressure shear homogenization, twice, and the pressure is 1600 bar.

[0088] (7) Put the homogenized slurry into a stirring tank, add 1...

Embodiment 3

[0095] (1) Chop the yew branches, dry, and crush through an 80-mesh sieve. The sieve is ready for use.

[0096] (2) Weigh 10 kg of the undersize, put it in a reflux extraction tank, add 2 times by mass of No. 6 solvent oil, and reflux for 2 hours to degrease.

[0097] (3) Suction filtration, recover No. 6 solvent oil, air-dry the filter residue, and set aside.

[0098] (4) Take the filter residue, put it in a heating and stirring tank, add 10 times the mass of water, stir and soak at a low speed at 50°C for 30 minutes. Make the yew powder residue fully absorb water to form a slurry.

[0099](5) Pour the slurry prepared in (4) into the colloid mill in batches, and grind for 5 minutes in a circular manner.

[0100] (6) Pour the slurry prepared in (5) into a high-pressure homogenizer, perform high-pressure shearing and homogenization twice, and the pressure is 800 bar.

[0101] (7) Put the homogenized slurry into a stirring tank, add 0.5% cellulase of the quality of the air-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com