Method for circularly absorbing SO2 in RFCC (Residue Fluid Catalytic Cracking) regenerative flue gas by utilizing ionic liquid

A technology for regenerating flue gas and ionic liquid, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as low solubility, difficult regeneration of sodium sulfate, and consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

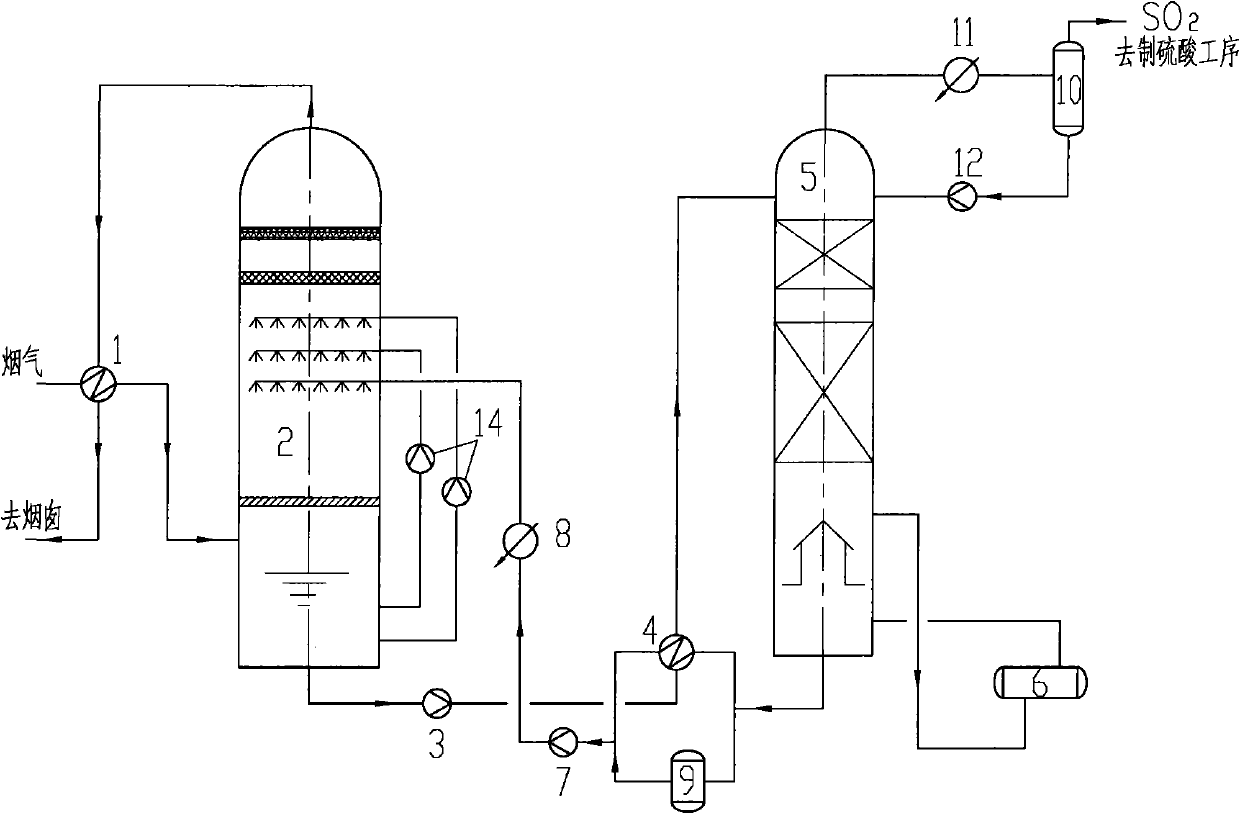

[0015] In order to make technical scheme and advantage of the present invention clearer, combine below figure 1 The specific embodiment of the present invention is described in further detail:

[0016] RFCC regenerated flue gas first cools down through the gas-gas heat exchanger (1), the cooled flue gas enters from the bottom of the absorption tower (2), and contacts with the ionic liquid desulfurizer entering from the top in countercurrent, and the absorption tower is equipped with a bottom-up Layer average cyclone flow plate, three-layer spray, two-layer defogging, the spray liquid comes from the bottom of the absorption tower and the lean liquid after analysis, which are respectively pressurized by the circulating pump (14) and the lean liquid pump (7); after purification The flue gas enters the gas-gas heat exchanger (14) from the top of the tower to exchange heat with the unpurified raw flue gas in the gas-gas heat exchanger (1), and the net flue gas after heating is dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com