Polypropylene carbonate/sodium sulfate transparent fully degradable composite material and preparation method thereof

A polypropylene carbonate and composite material technology, which is applied in the field of composite material preparation combining inorganic powder and polymer materials, to achieve the effect of reducing usage, reducing cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 A transparent and fully degradable composite material of poly(propylene carbonate) / sodium sodium sulfate. The composition and properties of the composite material are shown in Table 1. First weigh a certain amount of sodium sulfate and silane coupling agent (preferably γ-aminopropyltriethoxysilane coupling agent, the amount is 1wt% of the filler), and prepare the coupling agent into an anhydrous ethanol solution, first Add a certain amount of Yuanming powder (the particle size of Yuanming powder is 800 mesh, and the whiteness is greater than 90) into the high-speed mixer, stir and heat to 100°C, dry and exhaust, and then pump into the coupling in a fine mist under stirring agent solution, continue to stir for 15 minutes, discharge the material, and dry it at 100°C for 3 hours for later use; then put the polypropylene carbonate pellets, surface-modified sodium sulfate and lubricant stearic acid in a high-speed kneader according to the formula The amount of mix...

Embodiment 2-5

[0027] Example 2-5 A kind of transparent fully degradable composite material of poly(propylene carbonate) / sodium sulfate, first weigh a certain amount of sodium sulfate and silane coupling agent (preferably gamma-aminopropyl triethoxysilane coupling agent, consumption is 1 / 2 of filler 1wt%), the coupling agent was prepared into anhydrous ethanol solution, first a certain amount of sodium sulfate (the particle size of sodium sulfate is 3000 mesh, whiteness greater than 90) was added to the high-speed mixer to stir and heated to 100 ° C, dried Exhaust, then pump in the fine mist coupling agent solution under stirring, continue to stir for 15 minutes, discharge the material, dry at 100°C for 3 hours and set aside; then the polypropylene carbonate pellets, surface modified Yuanming powder and lubricants (paraffin and barium stearate) are mixed according to the formula dosage in a high-speed kneader, and then the mixture is transferred to an internal mixer for melting compounding,...

Embodiment 6-7

[0028] Example 6-7 A transparent and fully degradable composite material of polypropylene carbonate / sodium sodium sulfate, which is made of dried sodium sulfate (the particle size of sodium sulfate is 1800 mesh, and the whiteness is greater than 90), polypropylene carbonate pellets and lubricant hard Zinc fatty acid is mixed in a high-speed kneader according to the formula, and then the mixture is transferred to an internal mixer for melt compounding. The mixing speed is 50 rpm, and the temperature of melt compounding is controlled at 160°C. The obtained composite material was pressed into sheets by a flat vulcanizing machine, and the mechanical property test was carried out according to the standard sample preparation of ISO 527-2-2012; the light transmittance test was carried out according to GB2410-2008, and the thickness of the sample was 0.2mm. The composition and properties of the composite materials are shown in Table 1.

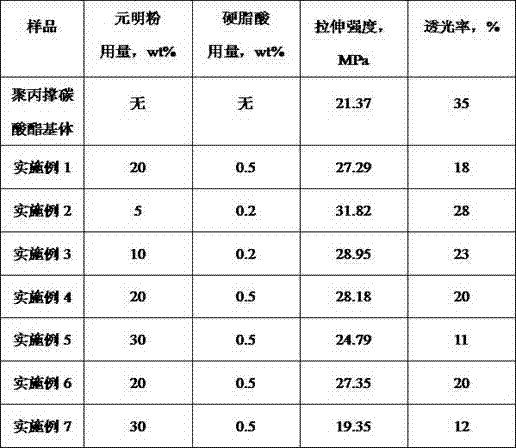

[0029] Table 1 Composition and properties o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com