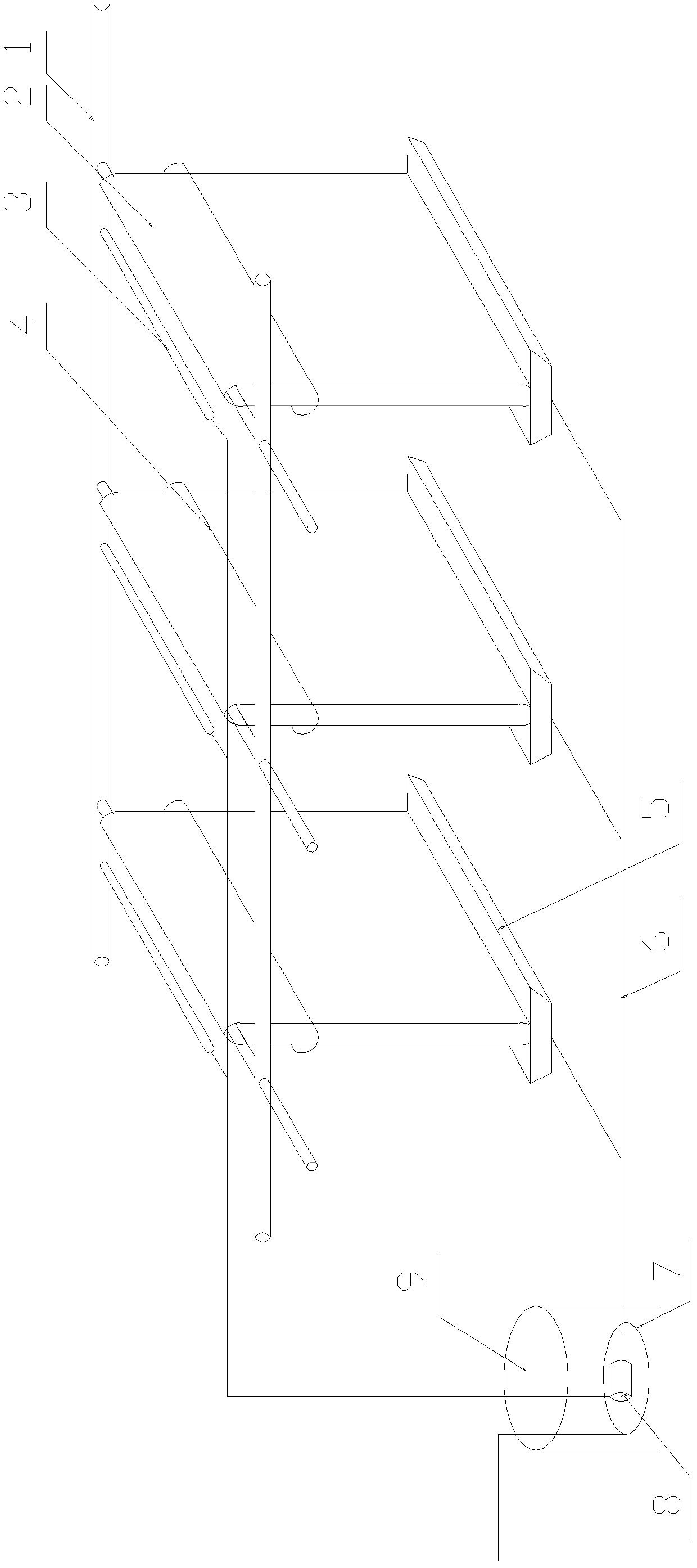

Inserting-plate type microalgae semi-dry solid adherent culture device

A semi-dry solid-state, adherent culture technology, applied in solid-phase fermentation bioreactors and other directions, can solve the problems of high energy consumption, large consumption of nutrient salts, and low utilization of light energy in large water bodies for stirring and mixing, and achieve cell growth. The state is easy to control, easy to add and remove, and the effect of high utilization of light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Five culture plates 2 are placed on a support truss 1 made of stainless steel. Each culture plate 2 is 40 cm long, 70 cm high, and 3 cm thick. The culture plate 2 is a multilayer polyurethane sponge composite. The culture plate 2 is covered with stainless steel except for the bottom edge. A double-sided stainless steel clip strip is installed on each culture plate 2 as a harvesting scraper. The distance between two adjacent culture plates 2 is 20 cm. The reservoir 9 is filled with Spirulina platensis (commercially available) culture medium (composition is per 1 liter of culture medium containing: 16.80 grams of sodium bicarbonate, 0.5 grams of potassium hydrogen phosphate, 2.5 grams of sodium nitrate, and sodium chloride 1.0g, 0.2g magnesium sulfate, 0.01g iron sulfate, 1.0g potassium sulfate, 0.04g calcium chloride monohydrate, 0.08g EDTA, adjust pH to 8.0 with NaOH solution). Spray the pre-cultured spirulina seed solution on the surface of the culture plate 2. The ...

Embodiment 2

[0035] Five culture plates 2 are placed on a stainless steel support truss 1, and each culture plate 2 is 40 cm long, 70 cm high, and 2.9 cm thick. The middle sandwich layer of the culture plate 2 is a polyurethane sponge with a thickness of 2.5 cm. The two outer layers of the sandwich layer are flocked cloth. The culture plate 2 is covered with stainless steel except for the bottom edge. A double-sided stainless steel clip strip is installed on each culture plate 2 as a harvesting scraper. The distance between two adjacent culture plates 2 is 20cm. The liquid storage bottle 9 is filled with Spirulina platensis (commercially purchased) medium (composition is that each 1 liter of medium contains: 16.80 grams of sodium bicarbonate, phosphoric acid Potassium hydrogen 0.5 g, sodium nitrate 2.5 g, sodium chloride 1.0 g, magnesium sulfate 0.2 g, iron sulfate 0.01 g, potassium sulfate 1.0 g, calcium chloride monohydrate 0.04 g, EDTA 0.08 g, adjust pH to 8.0 with NaOH solution ). S...

Embodiment 3

[0037] Five culture plates 2 are placed on a support truss 1 made of stainless steel. Each culture plate 2 is 40 cm long, 70 cm high, and 3 cm thick. The culture plate 2 is a polyurethane sponge, and the distance between two adjacent culture plates 2 is 20 cm. The reservoir 9 is filled with 10 liters of Spirulina platensis (commercially available) culture medium (composition of each 1 liter of culture medium contains: 16.80 grams of sodium bicarbonate, 0.5 grams of potassium hydrogen phosphate, 2.5 grams of sodium nitrate, chlorine Sodium sulfide 1.0 g, magnesium sulfate 0.2 g, iron sulfate 0.01 g, potassium sulfate 1.0 g, calcium chloride monohydrate 0.04 g, EDTA 0.08 g, pH 8.0 adjusted with NaOH solution). Spray the pre-cultured spirulina seed liquid on the surface of the culture plate 2. The supporting truss 1 is wrapped with transparent plastic film around and on the top, the device is placed outdoors, and the sunlight intensity at noon is 1500 μmol / m 2 / s, about 500μmol / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com