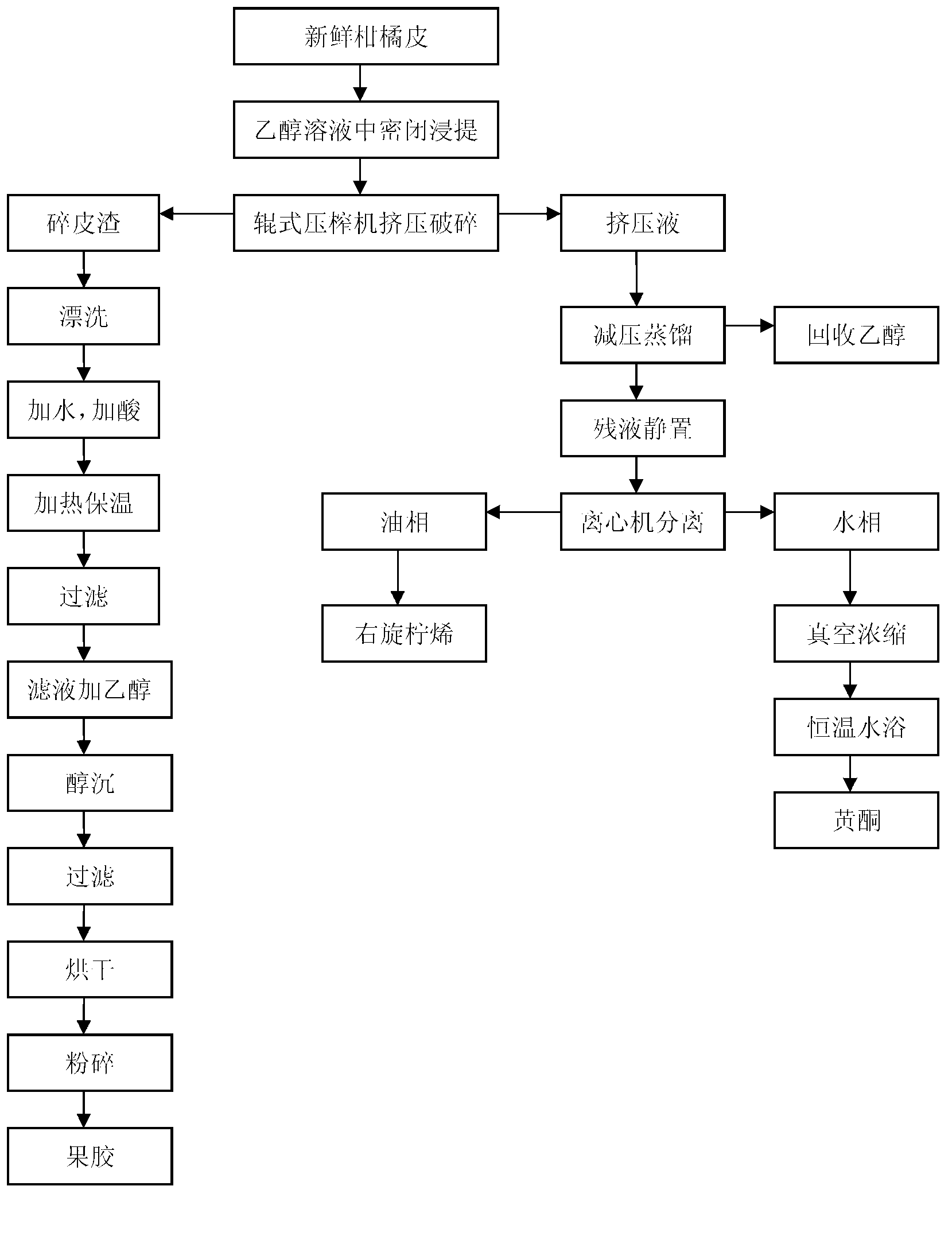

Method for combined extraction of D-limonene, flavonoid and pectin from orange peel

A technology of d-limonene and combined extraction, applied in chemical instruments and methods, purification/separation of hydrocarbons and hydrocarbons, etc., can solve the problems of inability to achieve combined extraction, waste of natural resources, low utilization efficiency of citrus peels, and the like, Achieve better quality, reduced labor costs, and whiter color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 100g of fresh sweet orange peel, cut into thin strips with a width of 0.5cm, add 1000ml of 95% ethanol solution, and soak in a sealed container for 8h. Use a roller press to perform 2 squeezes, and collect the broken skin residue and squeeze liquid respectively.

[0030] Add 1000ml of tap water to the broken skin and rinse 3 times, drain the water and then add 500ml of tap water, rinse with H 2 S 2 o 4 Adjust the pH to about 2.0, heat to 90°C for 30 minutes, and filter. Add an equal volume of 95% ethanol solution to the filtrate, ethanol precipitation for 1 h, filter through 150 mesh, and dry at 45°C to obtain 5.6 g of pectin (finished product).

[0031] Filter the squeeze liquid to remove debris, concentrate it to about 120ml with a rotary evaporator at a vacuum degree of -0.06MPa, and a temperature of 65°C. After standing for 2 hours, separate it with a disc centrifuge at 6000rpm, collect the oil phase, and obtain dextrorotary Limonene (crude product) 1.1ml....

Embodiment 2

[0034] Weigh 100g of fresh mandarin orange peel, cut into thin strips with a width of 0.5cm, add 1000ml of 95% ethanol solution, and soak in a sealed container for 8h. Use a roller press to perform 2 squeezes, and collect the broken skin residue and squeeze liquid respectively.

[0035] Add 1000ml of tap water to the broken skin and rinse 3 times, drain the water and then add 500ml of tap water, rinse with H 2 S 2 o 4 Adjust the pH to about 2.0, heat to 90°C for 30 minutes, and filter. Add an equal volume of 95% ethanol solution to the filtrate, ethanol precipitation for 1 h, filter through 150 mesh, and dry at 45°C to obtain 4.7 g of pectin (finished product).

[0036] Filter the squeeze liquid to remove debris, concentrate it to about 150ml with a rotary evaporator at a vacuum degree of -0.06MPa, and a temperature of 65°C. After standing for 2 hours, separate it with a disc centrifuge at 6000rpm, collect the oil phase, and obtain dextrorotary Limonene (crude product) 1.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com