Thermosetting resin composition as well as prepreg and laminated board manufactured by using thermosetting resin composition

A resin composition and prepreg technology, applied in the fields of electronic materials, high-frequency, high-speed and high-density interconnection, and integrated circuit packaging, can solve the problems of deteriorated board dielectric properties, low flame retardant efficiency, poor flame retardant properties, etc. The effect of sheet heat resistance or dielectric properties decline, high heat and humidity resistance, excellent dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

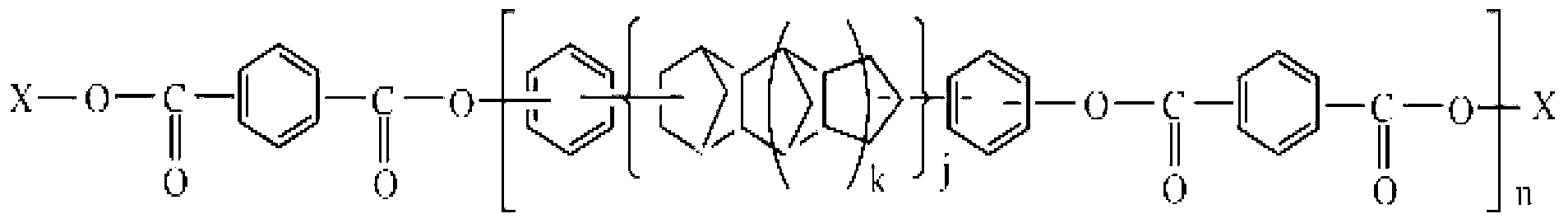

Image

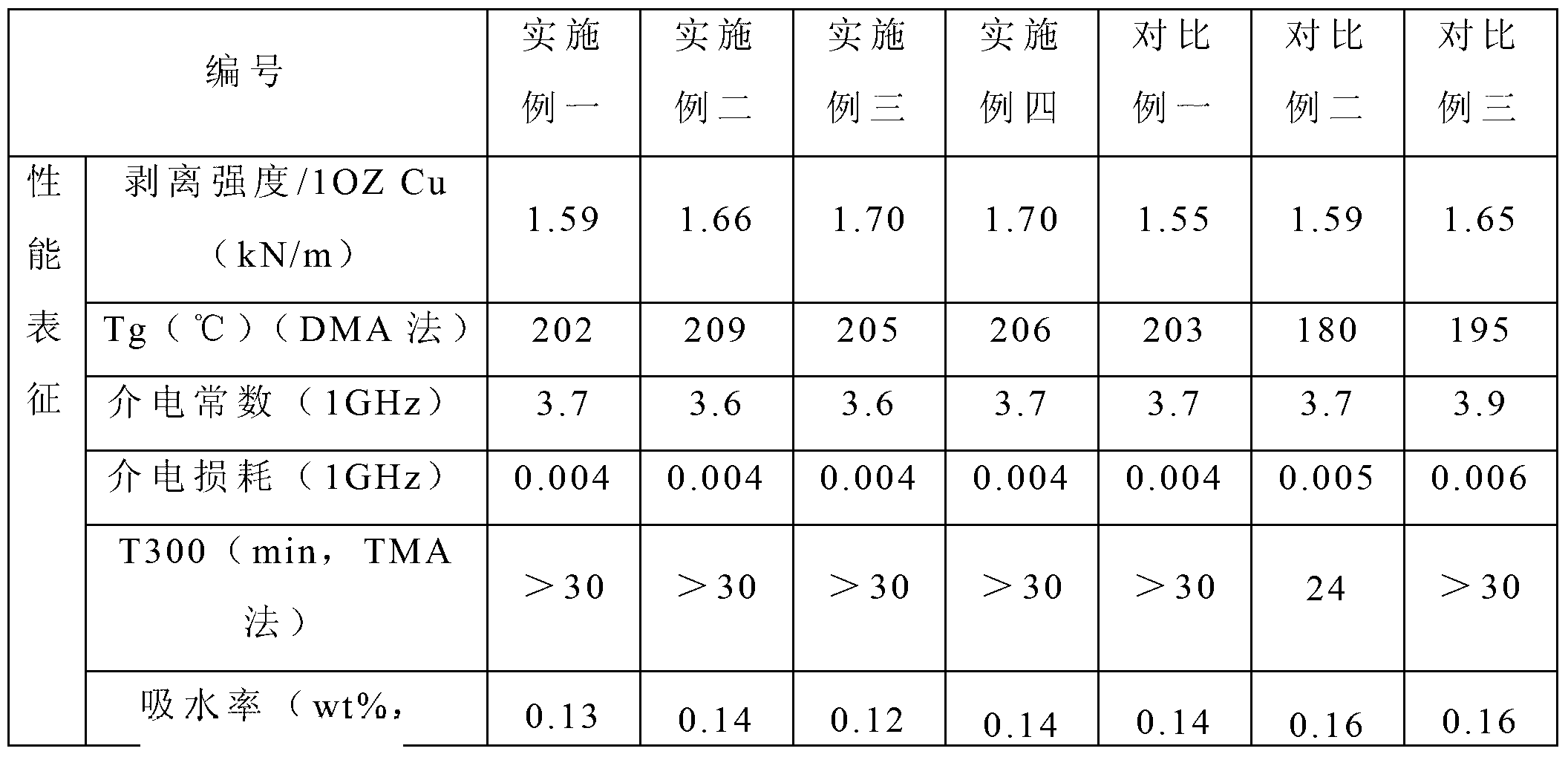

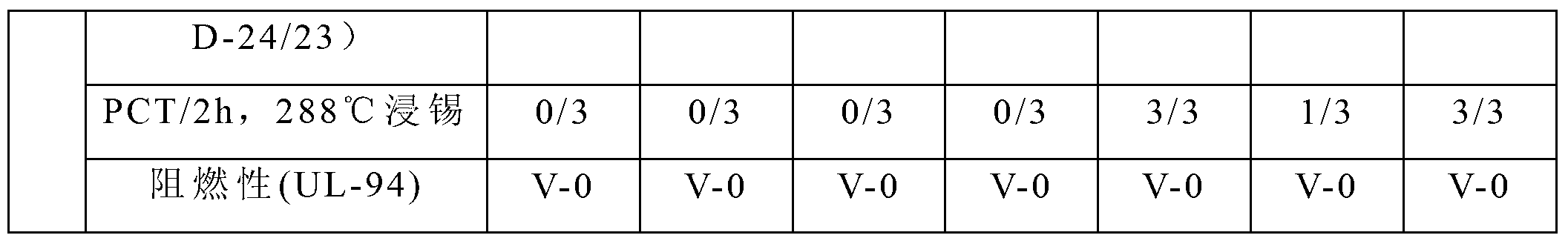

Examples

Synthetic example

[0038] Synthesis example: Synthesis of halogen-free flame retardant prepolymer

Synthetic example 1

[0040] Take bisphenol A type cyanate resin monomer 110g, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (hereinafter referred to as DOPO) 55g, 10-(2,5-di Hydroxyphenyl)-10-hydrogen-9-oxa-10-phosphaphenanthrene-10-oxide (hereinafter referred to as DOPO-HQ) 25g and 10-(2,5-dicarboxypropyl)-9,10 - Put 10g of dihydro-9-oxo-10-phosphaphenanthrene-10-oxide (hereinafter referred to as DDP) into the reaction bottle, slowly heat to 140°C in an oil bath, and keep stirring for 4 hours , after the reaction is completed, it is cooled to room temperature for use, and is recorded as PCE-1.

Synthetic example 2

[0042] Take 130g of tetramethylbisphenol F-type cyanate resin monomer, DOPO40g, DOPO-HQ20g and DDP10g into the reaction bottle, use an oil bath to slowly heat to 130°C, and keep stirring for 10 hours, the reaction is complete After cooling to room temperature for use, it was recorded as PCE-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com