Preparation method of nano lithium iron phosphate/carbon porous anode material with high-rate performance

A technology for lithium iron phosphate and positive electrode materials, which is applied in the field of high-rate performance nano-lithium iron phosphate/carbon porous positive electrode materials and its preparation, and can solve the problems of small free volume, low electronic conductivity, poor electronic conductivity and ion conductivity, etc. problems, to achieve high reversible cycle capacity, stable material performance, and good process repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

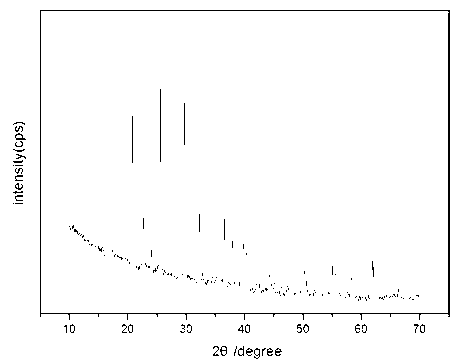

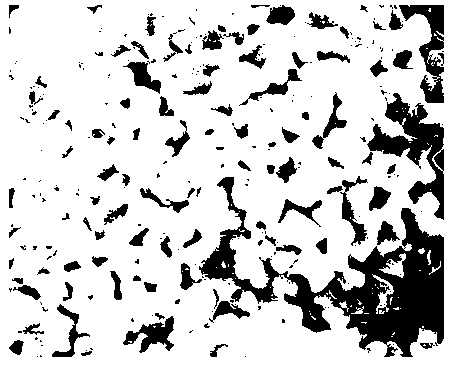

[0029] Grind P123 and ferrous oxalate evenly to obtain a well-mixed viscous mixture. Then add the stoichiometric ratio of H 3 PO 4 (85%), lithium hydroxide, the ball-to-material ratio is 10:1, and continue ball milling for 2 hours. The resulting mixture was placed in a closed reactor, reacted at a constant temperature of 120°C for 5 hours, dried at 105°C after cooling, and then heated up to 650°C at 5°C / min under the protection of nitrogen, and sintered at a constant temperature for 10 hours. Then cool down to room temperature, ball mill and pulverize to obtain lithium iron phosphate / carbon composite porous lithium ion positive electrode material. see figure 1 , it can be seen that the prepared material is a pure-phase pure-phase lithium iron phosphate material through X-ray diffraction measurement, and it is shown by scanning electron microscopy of the sample, see figure 2 , the primary particles of the prepared material are packed into a porous structure. This porous s...

Embodiment 2

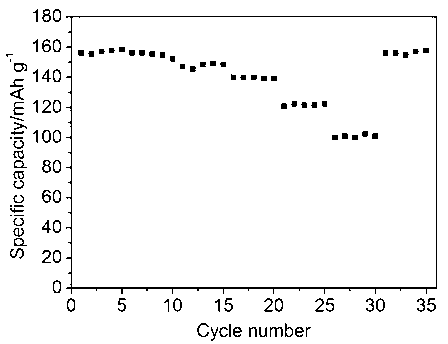

[0031] Grind and mix F168 and ferrous oxalate to obtain a well-mixed viscous mixture. Then add stoichiometric ammonium dihydrogen phosphate and lithium acetate, the ball-to-material ratio is 10:1, and continue ball milling for 5 hours. The resulting mixture was placed in a closed reactor, reacted at a constant temperature of 140°C for 5 hours, dried at 105°C after cooling, then heated up to 650°C at 5°C / min under nitrogen protection, and sintered at a constant temperature for 10 hours. Then cool down to room temperature, ball mill and pulverize to obtain lithium iron phosphate / carbon composite porous lithium ion positive electrode material. Electrochemical tests show that the discharge capacity of the prepared material reaches 106mAh / g at a rate of 10C, and the capacity retention rate is 95% after 100 cycles. Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com