Royal jelly solution and preparation method thereof

A manufacturing method and technology of royal jelly, applied in food preparation, application, food science, etc., can solve problems such as doubts about product quality, inconsistent with economic benefits, limited product preservation, etc., achieve the best process efficiency and economic benefits, reduce The effect of the handler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

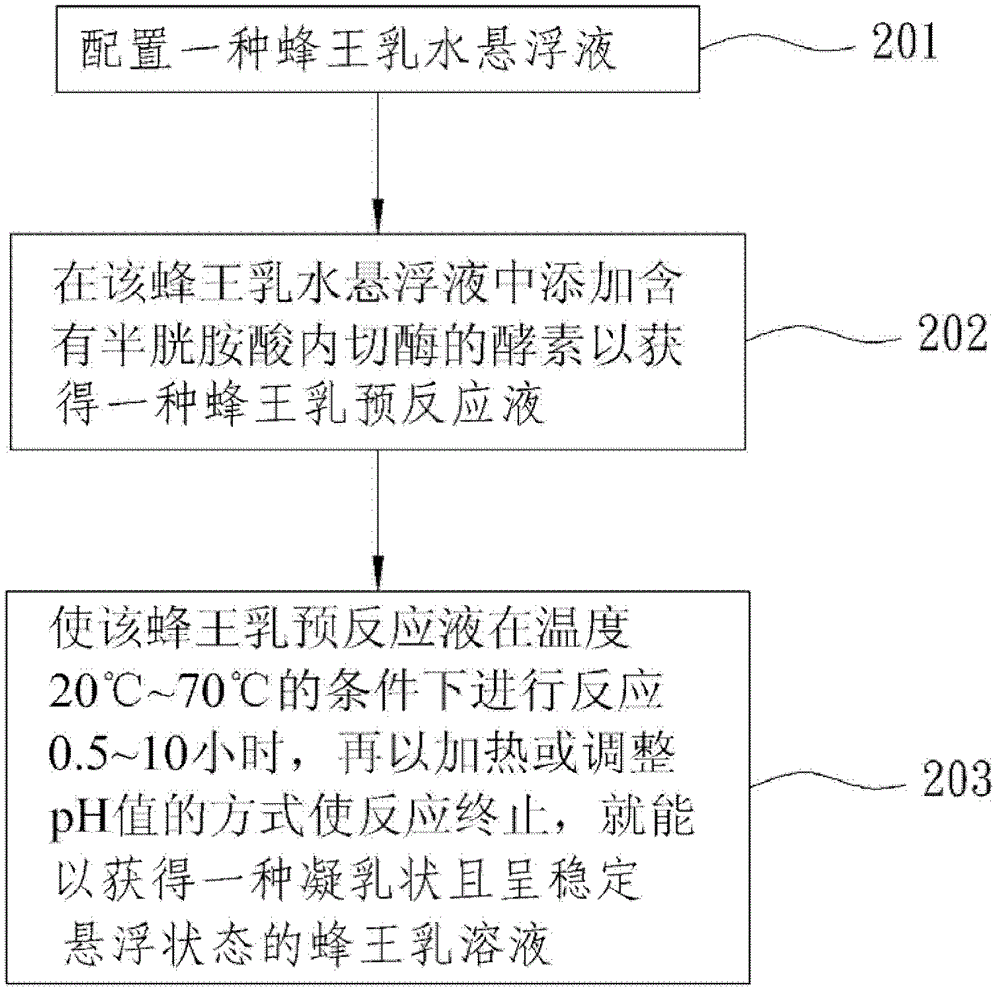

Method used

Image

Examples

specific example 1

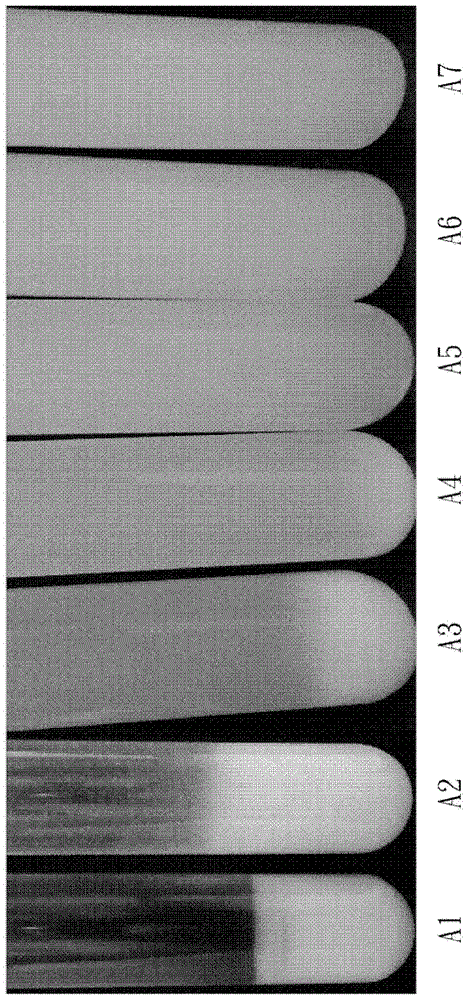

[0041] the treatment result comparison of existing ferment and ferment of the present invention

[0042] Put the prepared royal jelly water suspension into 7 test tubes numbered in sequence A1, A2, A3, A4, A5, A6, A7 respectively, the royal jelly concentration of the royal jelly water suspension in each test tube All are 5.8wt%, the royal jelly water suspension in each test tube is processed as follows respectively:

[0043]A1: Add pepsin in an amount equivalent to 0.1wt% of the royal jelly aqueous suspension and act at a temperature of 45°C for 6 hours, then add acid protease in an amount equivalent to 0.1wt% of the royal jelly aqueous suspension (Using protease derived from Aspergillus Oryzae), after reacting at a temperature of 45° C. for 6 hours, the pH value of the solution was adjusted to 5.5, and heated at a temperature of 80° C. for 10 minutes to terminate the enzyme action.

[0044] A2: The pH value of this royal jelly aqueous suspension is adjusted to 8, and the ne...

specific example 2

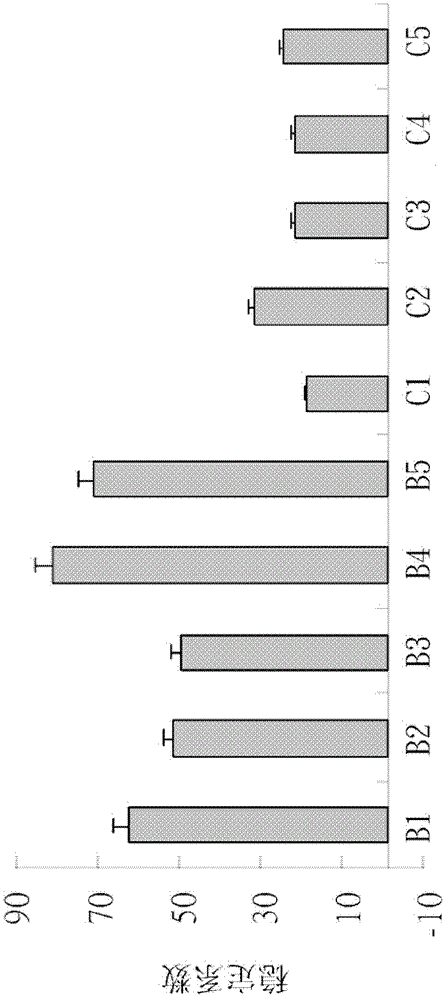

[0051] Test of solution stability, stability coefficient, active ingredient and suspension degree

[0052] Provide five royal jelly test solutions B1, B2, B3, B4 and B5 obtained by the manufacturing method of the present invention, and provide royal jelly test solutions C1, C2, C3, C4 and C5 obtained by general existing methods as Control comparison, and test and compare the precipitation rate, stability coefficient, decenoic acid content and stability, and suspension stability of the above test solutions. Wherein, the preparation methods of test solutions B1-B5 and test solutions C1-C5 are respectively as follows:

[0053] Test solution B1: Take 100g royal jelly and normal temperature water (about 25°C) and mix it uniformly to 1kg to make a 10wt% royal jelly aqueous suspension, and adjust its pH value to 4. After heating to 60°C, the This royal jelly aqueous suspension adds 10g of papaya enzyme (1% amount of the weight of royal jelly aqueous suspension) to obtain a royal je...

specific example 3

[0091] Identification of protein

[0092] Mainly adopt peptide mass fingerprinting (Peptide Mass Fingerprinting) technology, and use matrix-assisted laser desorption free time-of-flight mass spectrometer (MALFI-TOF-MASS, brand: Applied Biosystems Voyager-DE PR, operating mode: linear, polar Property: Positive charge, Voltage: 2000V, Mass range: 500-15000Da) Identify the protein quality in the prepared test solution. The protein identity identification test was carried out for the royal jelly water suspension without enzyme action-test solution D1, and the royal jelly solution obtained through different types and concentrations of enzymes under different action conditions-test solutions D2-D7. Test solutions D1-D7 are as follows:

[0093] Test solution D1: 6wt% royal jelly suspension without enzyme action.

[0094] Test solution D2: prepare 6wt% royal jelly aqueous suspension, add papaya enzyme equivalent to 0.1% of the weight of royal jelly aqueous suspension, and carry out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com