Common yam rhizome rice

A technology of yam rice and yam, applied in the fields of application, food preparation, food science, etc., to achieve the effect of improving nutritional structure, delicate taste, and good palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

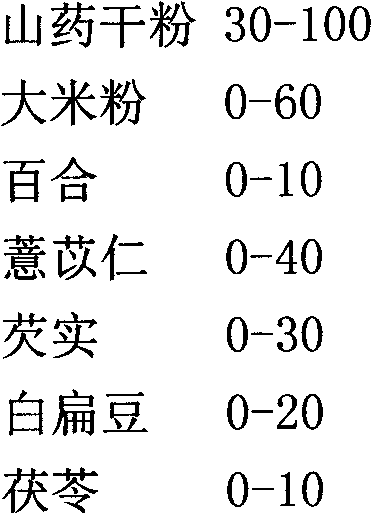

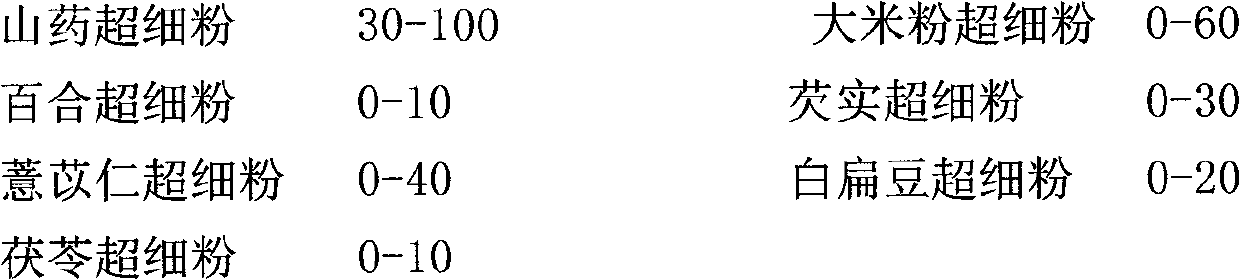

Method used

Image

Examples

example 1

[0025] Taking 100 kg of finished yam rice as an example, follow the steps below: the ratio of raw materials used is: 100% of yam freeze-dried granules. The freeze-dried yam particles are pre-screened to remove impurities, and then the raw materials are further dedusted, including electrostatic dust removal and high-pressure dust removal. The raw materials are crushed by multi-stage crushing, and the crushed particles are screened by inspection sieves. Separately recover and re-grind to obtain superfine powder of raw materials. The ultrafine powder obtained by crushing the freeze-dried yam granules should have a fineness of more than 140 mesh. Stir the obtained superfine yam powder evenly, weigh according to the formula, add water according to 25%-35% of the raw material powder mixture, and mix and stir evenly. The obtained raw material mixture is processed by the process of "expanding extrusion, moderate aging, cooling granulation". The specific method is: puffing and extrus...

example 2

[0028] Take 100 kg of finished yam rice as an example, follow the steps below: the proportion of raw materials used is: 90% of yam freeze-dried granules, 10% of rice

[0029]Pre-screen yam freeze-dried granules and rice to remove impurities, and then further dedust the raw materials and rice, including electrostatic dust removal and high-pressure dust removal, and use multi-stage crushing for raw materials, and use inspection sieves to screen the crushed particles. Particles with unqualified size are recovered separately and re-grinded to obtain superfine powder of raw materials. The ultra-fine powder obtained by crushing the freeze-dried yam granules and rice should have a fineness of more than 140 mesh. Stir the obtained yam superfine powder and rice flour evenly, weigh according to the formula, add water according to 25%-35% of the raw material powder mixture, and mix and stir evenly. The obtained raw material mixture is processed by the process of "expanding extrusion, mo...

example 3

[0032] The ratio of the used raw material formula is (calculated by weight percentage): 60% of yam superfine powder, 30% of rice superfine powder, and 10% of Gorgon superfine powder. The processing technology is as above, no longer described.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com