Method for reuse of reclaimed water in circulating cooling water

A technology for circulating cooling water and reclaimed water, which is applied in chemical instruments and methods, water/sludge/sewage treatment, descaling and water softening, etc. Bio-sludge formation, reduction and water treatment costs, and the effect of reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12 and comparative example 1-9

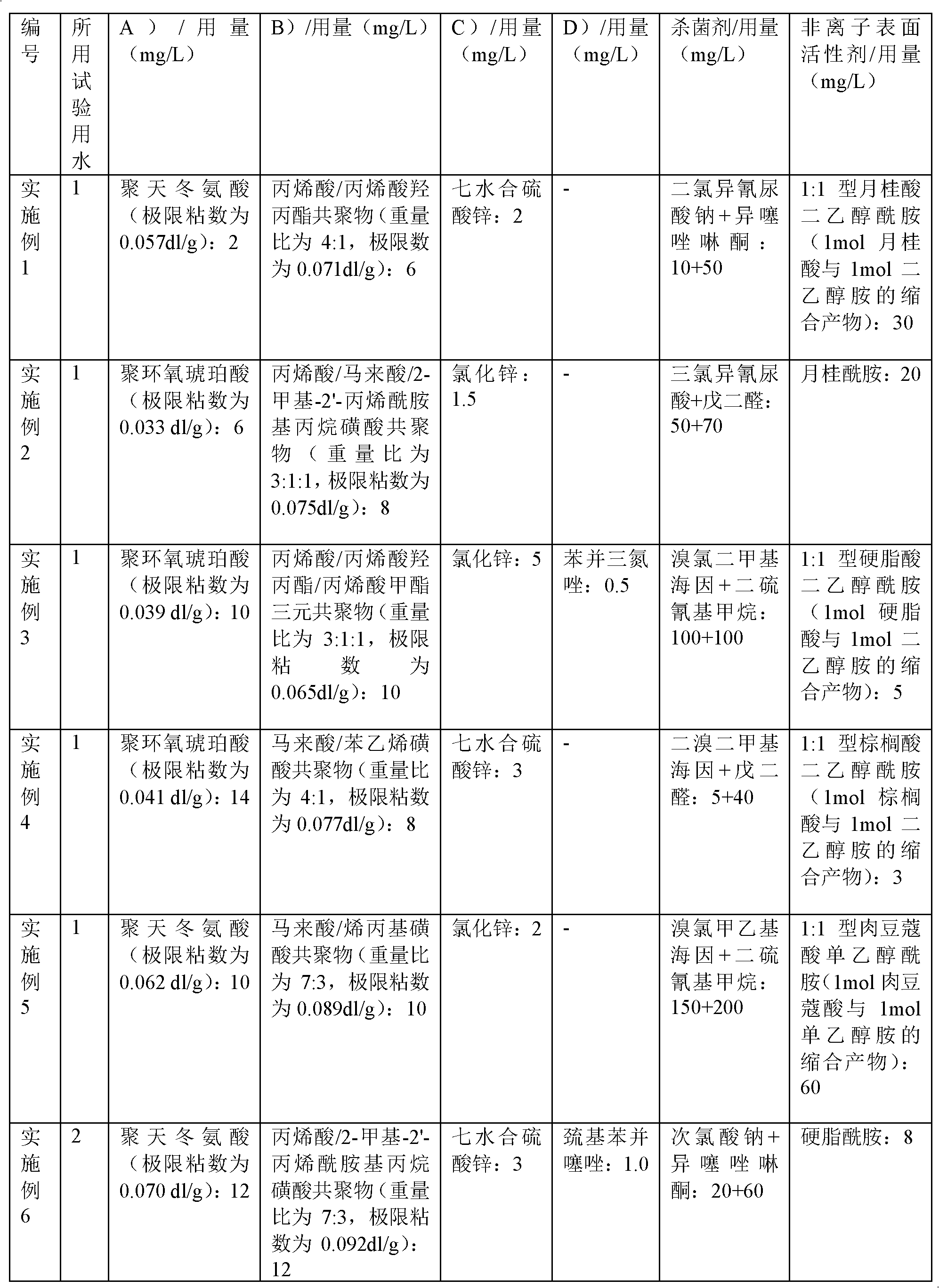

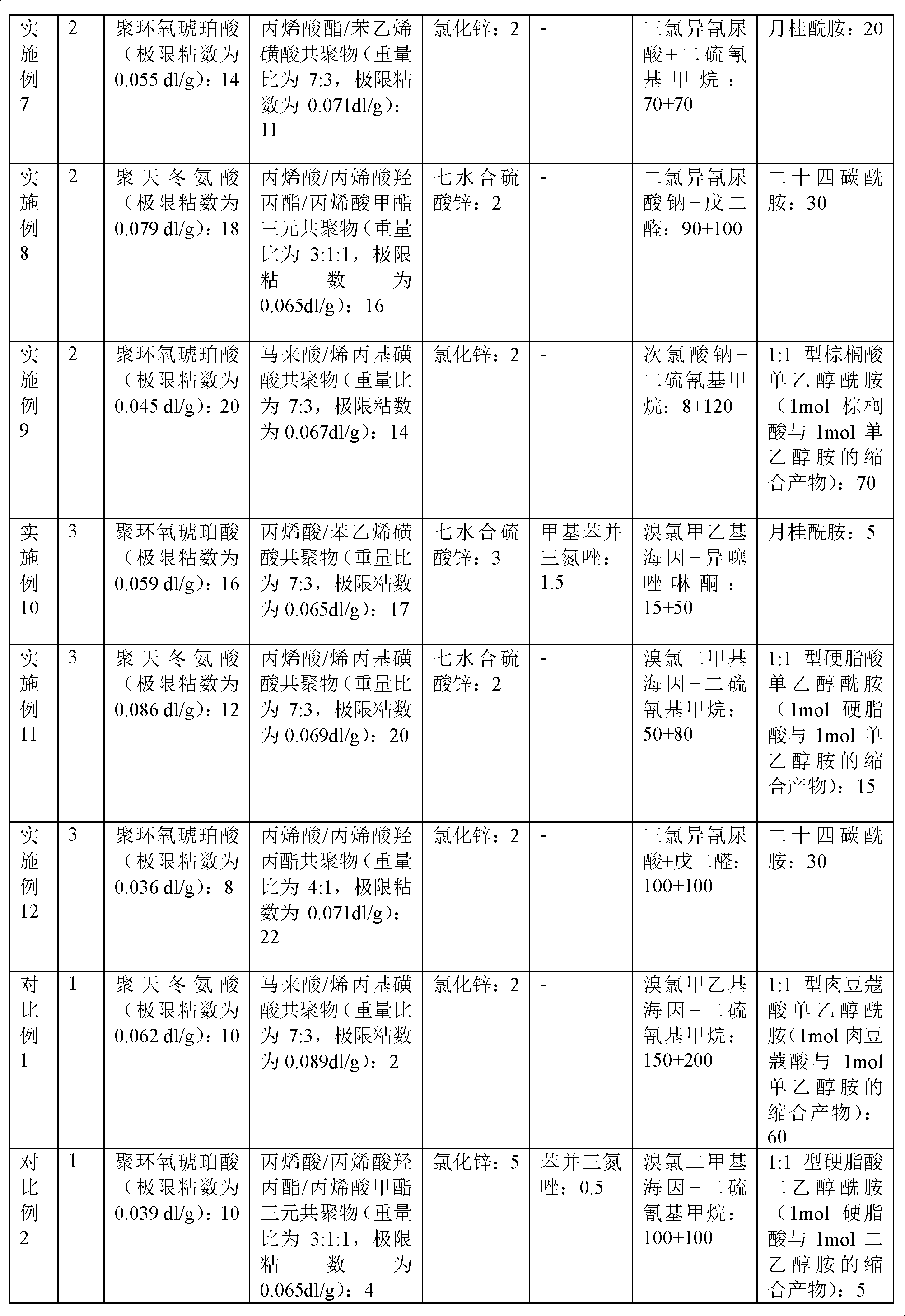

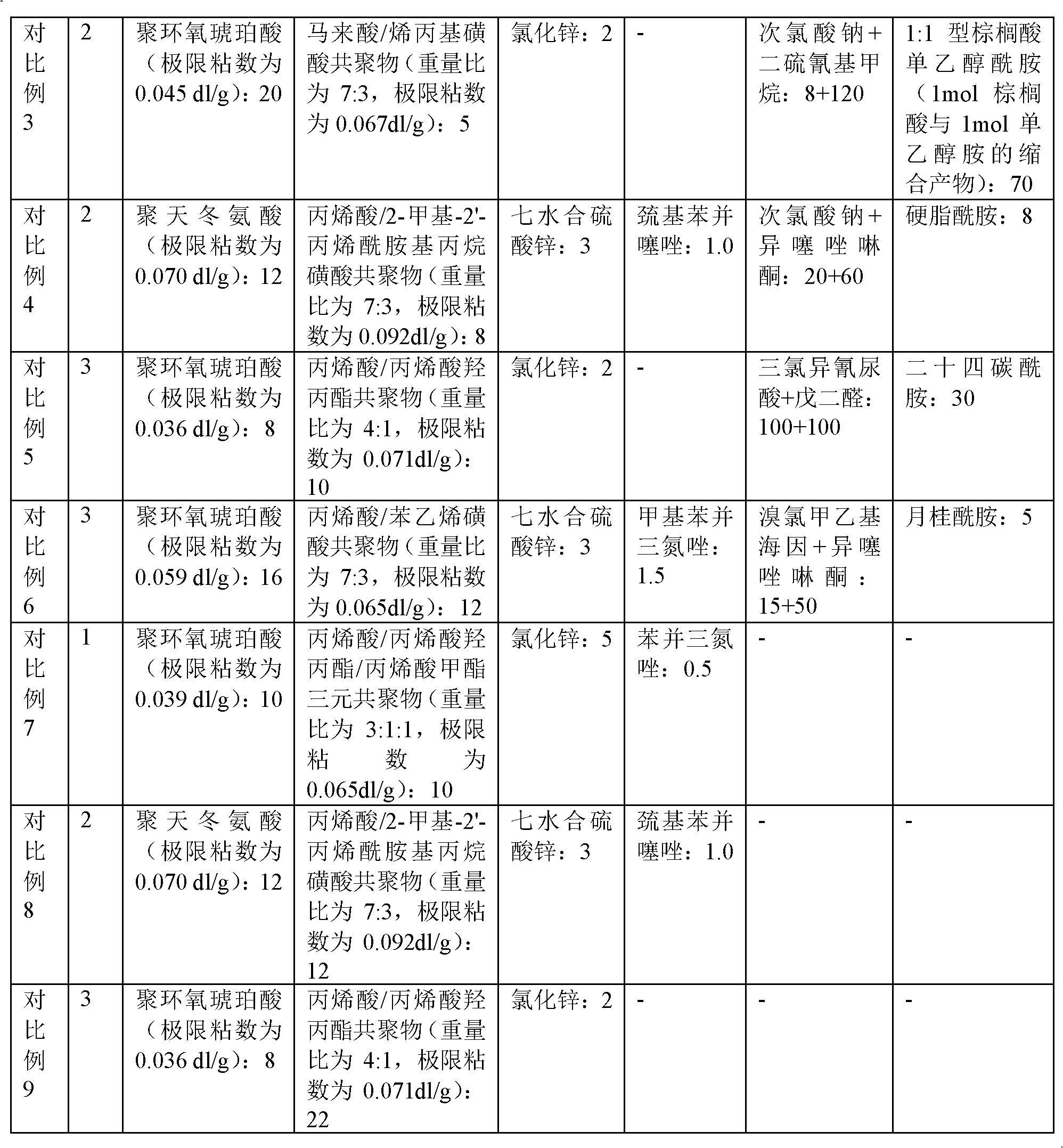

[0045] Examples 1-12 and comparative examples 1-9 are used to illustrate the corrosion inhibition effect and calcium phosphate scale inhibition effect of the method of the present invention and the reference method of the present invention.

[0046] Supplement Ca in Filtrate 1, Filtrate 2 and Filtrate 3 in Table 2 2+ and PO 4 3- The amount until the concentration multiple is 5 times is equivalent to the circulating cooling water when the reclaimed water is used as the supplementary water of the circulating cooling water, and the treated water is used as the test water for the corrosion inhibition effect and the calcium phosphate scale inhibition effect test. Orthophosphorus concentrations were as follows:

[0047] table 3

[0048] project

Test water 1

Test water 2

Test water 3

Orthophosphorus / (mg / L)

2.92

6.68

13.65

[0049] The test methods for performance evaluation of scale and corrosion inhibitors are as follows:

[00...

Embodiment 13-15 and comparative example 10-13

[0076] This example and comparative example are used to illustrate the scale and corrosion inhibition effects of the method of the present invention and the reference method and the inhibition effect on heterotrophic bacteria.

[0077] According to the chemical industry standard HG / T 2160-91 of the People's Republic of China, the dynamic simulation test is carried out, and the test control parameters are as follows:

[0078] Concentration multiple (indicating the ratio of the salt content of the circulating cooling water to the salt content of the make-up water): 5.0±0.2

[0079] System velocity of circulating water: 1.0m / s

[0080] The temperature of the circulating water at the inlet of the heat exchanger: 32±1°C

[0081] Temperature difference between inlet and outlet of circulating water: 10℃

[0082] pH value of circulating water: 8.0.

Embodiment 13

[0084] This example is used to illustrate the method of reclaiming reclaimed water for circulating cooling water provided by the present invention.

[0085] (1) According to filtrate 1 in table 2, join in the circulating cooling system as supplementary water, after the concentration multiple of circulating cooling water reaches 5, the concentration of orthophosphorus in circulating water is 2.95mg / L, add polymer respectively in circulating cooling water Aspartic acid (limiting viscosity is 0.059dl / g), acrylic acid / styrenesulfonic acid copolymer (weight ratio is 7:3, limiting viscosity is 0.081dl / g) and zinc sulfate heptahydrate, the effective concentrations are respectively 6mg / L, 8mg / L, 2mg / L;

[0086] (2) Add sodium dichloroisocyanurate, isothiazolinone, sodium dichloroisocyanurate and lauramide every three days to the circulating water obtained in step (1), and the dosing concentration is 50mg / L and 70mg respectively / L, 50mg / L and 10mg / L.

[0087] (3) After 15 days of te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com