Preparation method of temperature-resisting lead-free and barium-free primary explosive 5-nitramino tetrazole calcium

A technology of calcium nitramine tetrazolium and tetrazole nitrazole, which is applied in the field of preparation of 5-calcium nitramine tetrazolium detonating agent, can solve the problems of difficult operation, application influence, application limitation and the like, and achieves the effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

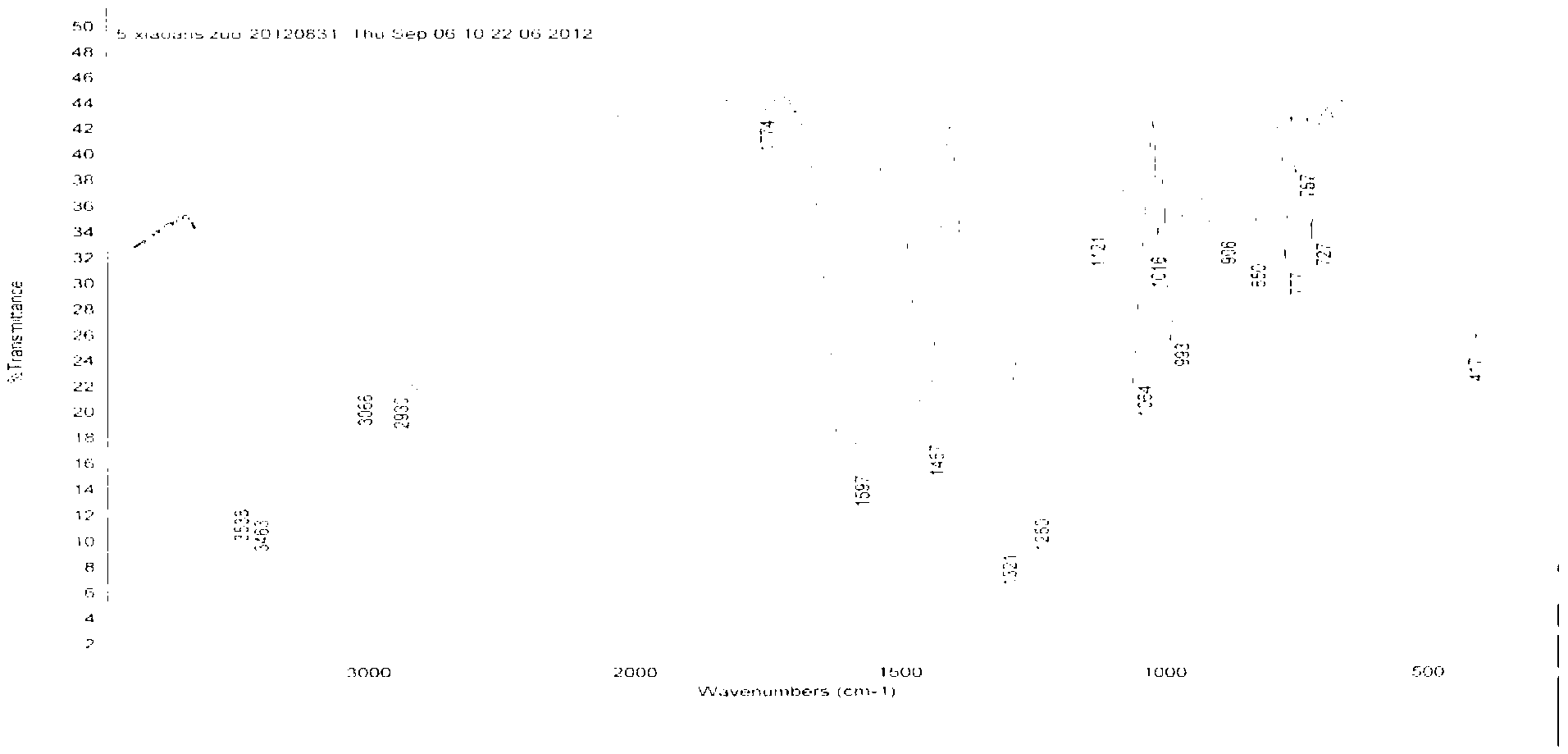

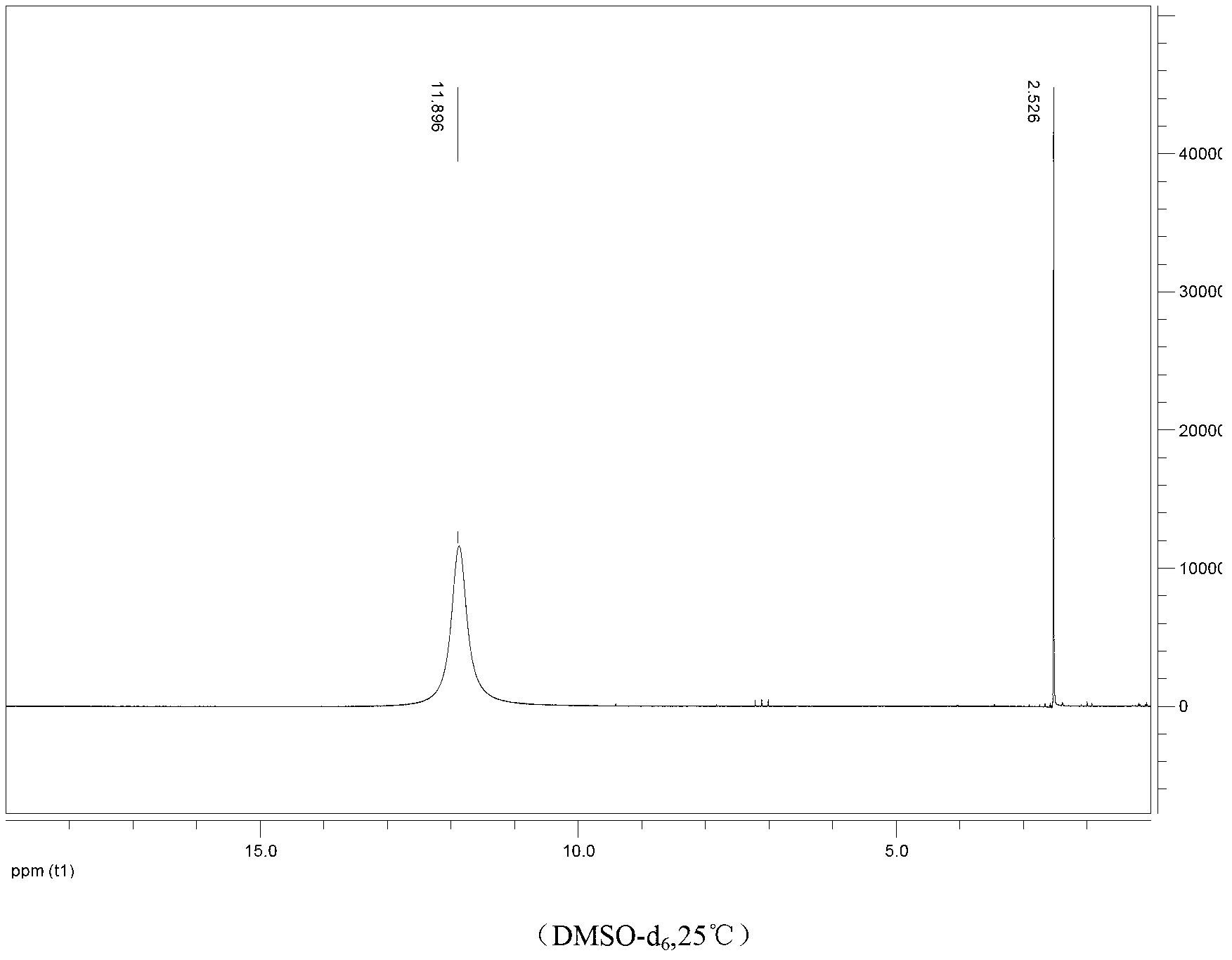

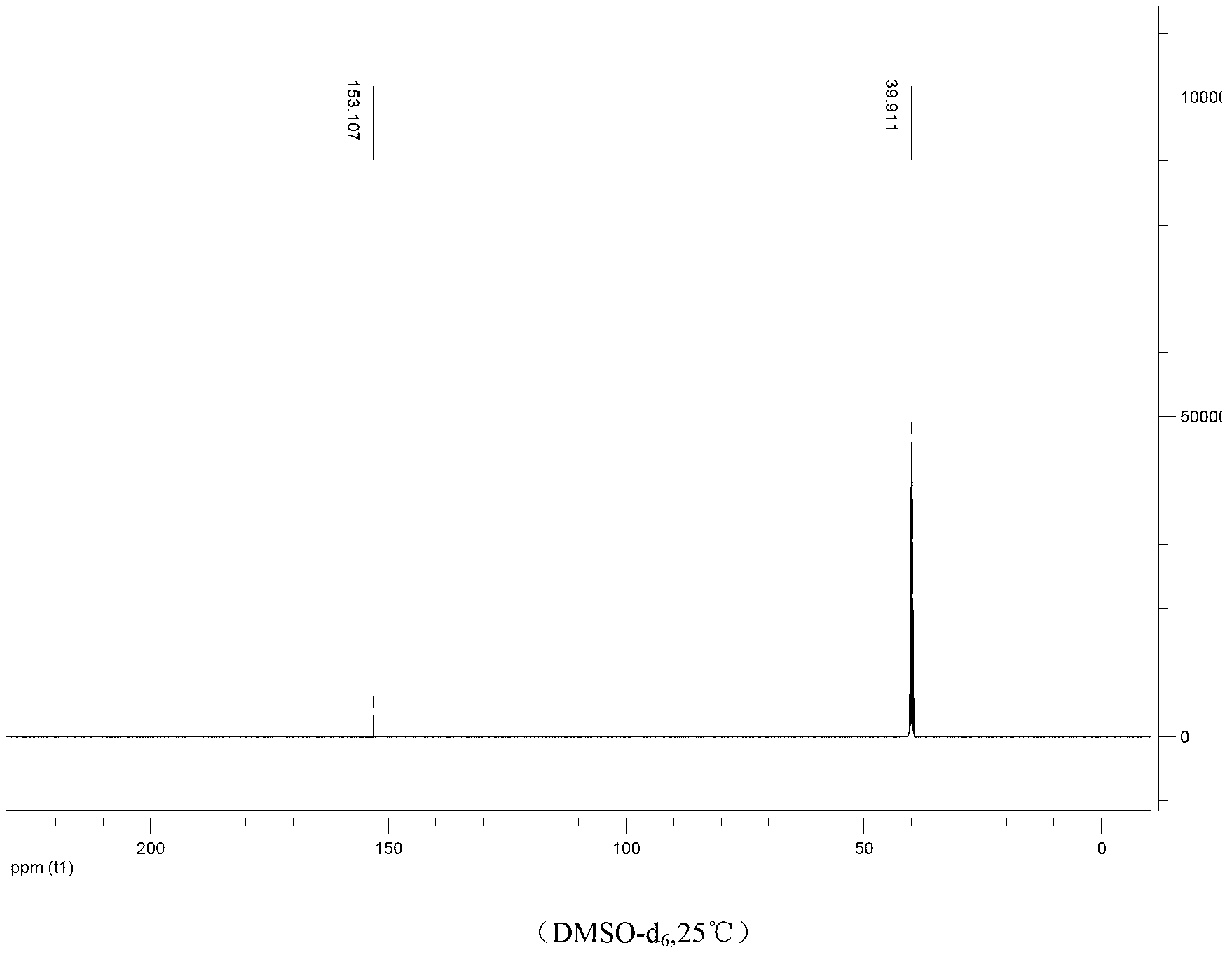

Method used

Image

Examples

preparation example Construction

[0017] The present invention provides a kind of preparation method of novel priming agent——5-nitroaminotetrazole calcium (II), and the preparation process is divided into two steps:

[0018] (1) Preparation of 5-nitroaminotetrazole:

[0019]

[0020] (2) Preparation of 5-nitroaminotetrazole calcium:

[0021]

[0022] The technical solution adopted by the present invention to solve its technical problems is:

[0023] (1) Add fuming nitric acid with a mass concentration of 98% in the reaction flask, cool in an ice bath, add dropwise concentrated sulfuric acid with a mass concentration of 98%, HNO 3 :H 2 SO 4 The mass ratio is 1:1. The 5-aminotetrazole powder was added with stirring. Raise the temperature to 50-70°C and react for 4-6 hours, cool to room temperature and add anhydrous Na 2 CO 3 to neutral pH. Extract with absolute ethanol, rotary evaporate the filtrate, add ethyl acetate to produce a white precipitate, filter the solid product, and dry it at 60±5°C to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com