Preparation method of biodiesel

A technology of biodiesel and waste oil, which is applied in the fields of biofuel, petroleum industry, fatty acid production, etc., can solve the problems of unsuitable diesel production enterprises for wide application, incomplete reaction, and unqualified products, so as to improve urban air quality and shorten the Short esterification reaction cycle and short construction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the biodiesel disclosed in the present invention mainly uses waste oil as raw material, the main components of which are triglycerides and higher fatty acids, and two different products can be prepared according to actual production needs:

[0033] 1. Product a with biodiesel as the main component. The methanol and dimethyl carbonate contained in this product are used as oxygen enhancer components, which greatly improve the thermal efficiency of fatty acid methyl esters, reduce exhaust emissions, and improve urban air quality;

[0034] 2. Product b, containing 100% fatty acid methyl ester, can blend diesel and fuel oil in any proportion, and can flexibly adjust products according to market demand.

Embodiment 1

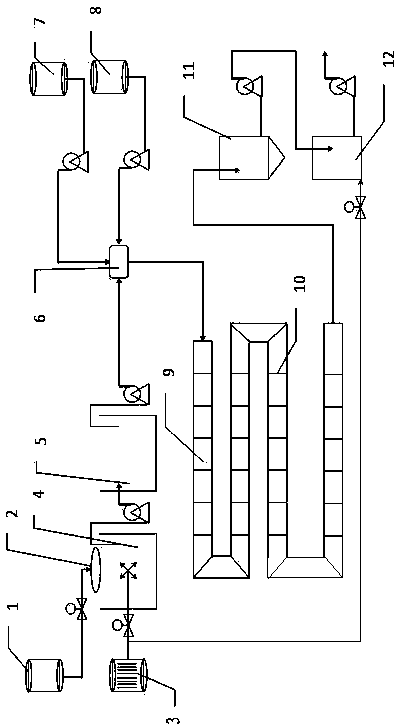

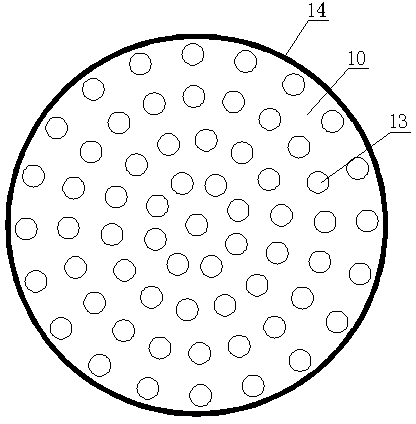

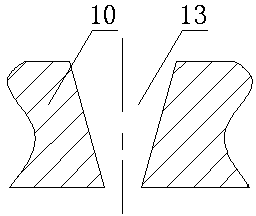

[0036] 10 tons of swill oil (50% triglyceride, 50% fatty acid) is unloaded to the raw material pool 4 for pretreatment, and the steam produced by the steam boiler 3 is passed into the raw material pool, and the temperature is raised to 90°C for heat preservation. 500KG concentrated sulfuric acid comes from Sulfuric acid storage tank 1 is evenly sprayed onto the surface of the raw material oil in the raw material pool through the sulfuric acid distributor 2, and left to stand for 10 hours. The tank 7 and the co-solvent storage tank 8 are simultaneously metered and discharged, and the flow rates are 5000L / h, 1250L / h, and 750L / h respectively. The three raw materials are mixed in the buffer 6 and then enter the continuous tubular reactor 9 for continuous reaction. The total volume of the tubular reactor is 10000L, and there are 200 microporous baffles 10 inside it. The whole reaction process is about 2.5 hours. , put acid water every 0.5h, repeat 4 times to get crude methyl ester,...

Embodiment 2

[0038] Acidified oil (30% triglyceride, 70% fatty acid) is 10 tons, unloaded to the raw material pool 4 for pretreatment, the steam produced by the steam boiler 3 is passed into the raw material pool, the temperature is raised to 80°C for heat preservation, and 250KG concentrated sulfuric acid comes from Sulfuric acid storage tank 1 is evenly sprayed onto the surface of the raw material oil via distributor 2, and left to stand for 7 hours. The upper layer of pretreated oil is extracted to the pretreated oil temporary storage pool 5, and then from the pretreated oil temporary storage pool 5, the methanol storage tank 7, and the co-solvent The storage tank 8 measures and discharges the material at the same time, and the flow rates are 5000L / h, 1500L / h, and 600L / h respectively. After being mixed in the mixing buffer 6, the three raw materials enter the continuous tubular reactor 9 for continuous reaction. The continuous tubular reactor The total volume is 15,000L, and there are 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com