Comprehensive utilization method of oil-tea camellia shells

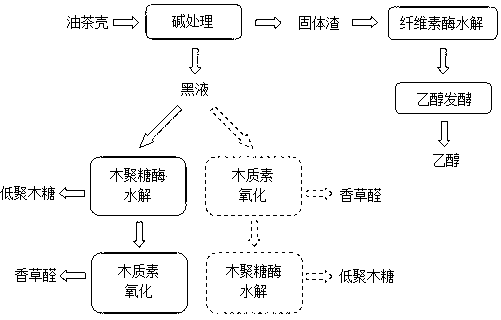

A technology of camellia oleifera shell and solid-liquid separation, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, separation/purification of carbonyl compounds, etc., to achieve high-value utilization and reliability, and to reduce environmental pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Alkaline pretreatment of camellia oleifera shell

[0027] (1) Camellia oleifera husks (the contents of cellulose, xylan and lignin are 14.02%, 28.61% and 44.35% respectively) are crushed to 0.2-0.4mm and set aside.

[0028] (2) Sodium hydroxide pretreatment: The pulverized camellia oleifera shells were pretreated with sodium hydroxide, and orthogonal experiments were used to optimize the pretreatment conditions. The main variables and conditions were as follows: NaOH concentration (10%, 12%, 14 %), temperature (110, 115, 120°C), time (90, 120, 150min), liquid-solid ratio (10.0, 12.5, 15.0). The details are shown in Table 1.

[0029] Table 1 Orthogonal experiment L 9 (3 4 ) factor level table

[0030]

[0031] (3) Solid-liquid separation: After pretreatment, use G 1 Suction filtration through the filter for solid-liquid separation, and 300 mL of distilled water was added to wash the solid residue three times, and the filtrate was collected for later use...

Embodiment 2

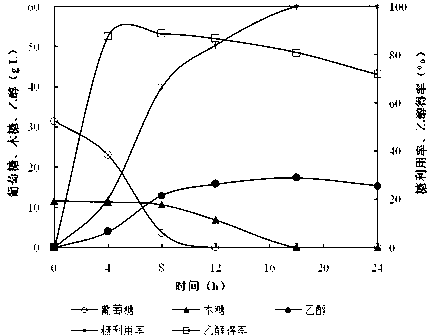

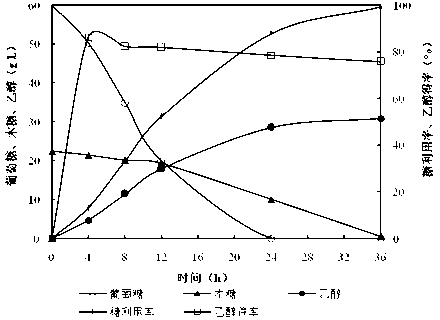

[0040] Example 2: Preparation of fuel ethanol by fermentation of enzymatic hydrolyzate

[0041]The solid slag pretreated by the camellia husk alkali method is hydrolyzed by cellulase, and the obtained monosaccharide is used for ethanol fermentation. Glucose and xylose are contained in the enzymatic hydrolyzate, and Pichia stipitis, a strain capable of utilizing glucose and xylose ( Pichia stipitis CBS 5776) for ethanol fermentation. The enzyme hydrolyzate fermentation includes the direct ethanol fermentation of the enzyme hydrolyzate and the ethanol fermentation after the enzyme hydrolyzate is concentrated by one time. Fermentation medium composition: 5g (NH 4 ) 2 SO 4 , 3g KH 2 PO 4 , 0.5g MgSO 4 ·7H 2 O, 30mg EDTA, 9mg ZnSO 4 ·7H 2 O, 2 mg MnCl 2 2H 2 O, 0.6 mg CoCl 2 ·6H 2 O, 0.6 mg CuSO 4 ·5H 2 O, 0.8 mg Na 2 MoO 4 ·H 2 O, 9 mg CaCl 2 2H 2 O, 6mg FeSO 4 ·7H 2 O, 2 mg H 3 BO 3 , 0.2 mg KI. Adjust the pH to 6.0 with sodium hydroxide. The initial ...

Embodiment 3

[0050] Embodiment 3: adjust pH value to separate xylan and lignin

[0051] Take 30mL of black liquor after optimal pretreatment (Example 1) in a 50mL centrifuge tube, add 72% sulfuric acid to adjust the pH value of the black liquor to about 1, 2, 3, 4, 5, 6, 7 respectively . After equilibrium, centrifuge at 10,000 r / min for 5 minutes, then separate the solid from the liquid, collect the solid precipitate and the supernatant, and measure the volume of the supernatant for later use.

[0052] Take 10mL of supernatant in a 50mL Erlenmeyer flask, add 10mL of 8% sulfuric acid, seal it with a parafilm, react at 121°C for 60min, take it out after cooling, and use G 3 Filter through a glass sand funnel, collect the filtrate and record the volume. Liquid part: mainly analyze the content of acid-soluble / acid-insoluble lignin and xylan.

[0053] The obtained solid precipitate was washed with distilled water and the volume was adjusted to 25 mL. Take 10mL of uniformly mixed suspension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com