Device for washing and desulfurating waste gas of marine diesel engine

A marine diesel engine and exhaust gas washing technology, applied in water/sludge/sewage treatment, dispersed particle separation, water/sewage multi-stage treatment, etc., can solve the problems of increasing investment and operating costs, large washing diameter, large pressure drop and resistance and other problems, to achieve the effect of facilitating absorption and reaction, large gas-liquid contact area, and reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

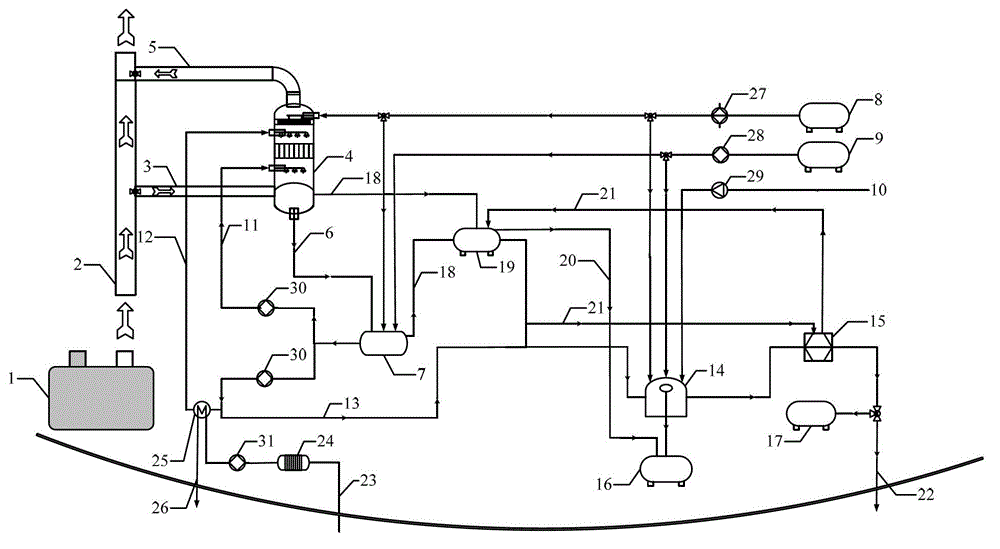

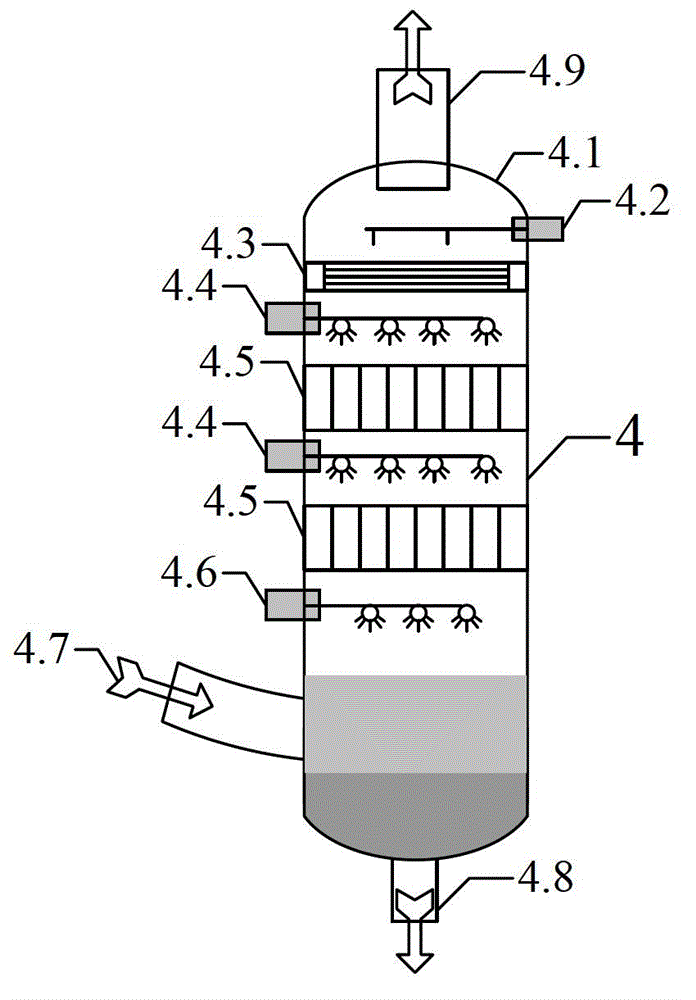

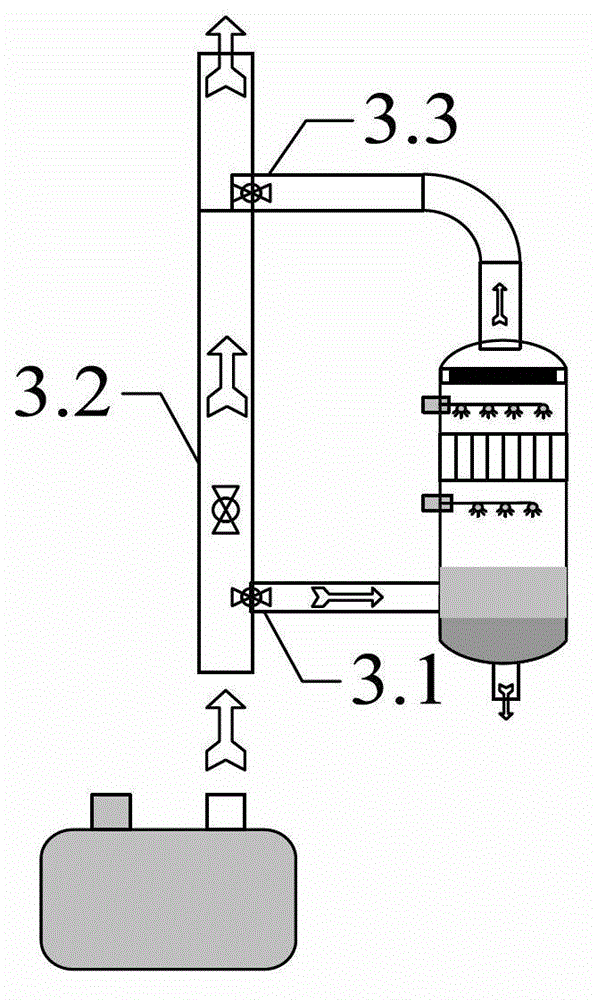

[0027] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0028] to combine Figure 1~4 , the present invention comprises a diesel engine 1, an exhaust pipe 2, an exhaust gas inlet pipeline 3, an absorption tower 4, an exhaust gas outlet pipeline 5, a circulating fluid pipeline 6, a circulating fluid treatment tank 7, a fresh water tank 8, a NaOH solution storage tank 9, External environment 10, high temperature spray pipeline 11, low temperature spray pipeline 12, waste liquid sewage pipeline 13, waste liquid treatment system 14, waste liquid detection system 15, oil storage tank 16, waste liquid storage tank 17, washing liquid Overflow pipeline 18, washing liquid buffer tank 19, waste liquid overflow pipeline 20 waste liquid detection pipeline 21, sewage pipeline 22, cooling water inlet pipeline 23, seawater processor 24, cooler 25, cooling water outlet pipeline 26. Fresh water pump 27, alkali resistant pump 28, air p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com