Biosurfactant and preparation method thereof

A biological surface and active agent technology, applied in chemical instruments and methods, drilling compositions, chemical/physical processes, etc., can solve the problem of high cost of surfactants, achieve low price, avoid huge damage, and good emulsification performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The enzyme-catalyzed hydrolysis of embodiment 1 protein

[0049] Accurately weigh 15g of protein powder, dissolve in 250mL of deionized water, stir and heat to 50°C, and preheat for 10min. Adjust the pH value to 9.5±0.05 with 2M NaOH, and add 200-400 μL of enzyme solution for hydrolysis. A 905Titrando automatic potentiometric titrator was used to add 1M NaOH solution dropwise to control the pH value of the reaction system to be 9.45-9.55. The hydrolysis reaction generally lasts for 30 minutes. After the end, the pH of the solution is adjusted to 4.0 with concentrated hydrochloric acid to inactivate the activity of alkaline protease Protex 6L. Protein polypeptides with different degrees of hydrolysis are prepared by controlling the amount of protease added and the hydrolysis time. The degree of hydrolysis of the protein polypeptide was calculated by measuring the concentration of free amino acids in the hydrolyzate by the OPA method, and a standard curve was drawn with...

Embodiment 2

[0053] The acid-catalyzed hydrolysis of embodiment 2 protein

[0054] Add 10 mL of 12.0 mol / L concentrated hydrochloric acid to 10 mL of 60 g / L protein aqueous solution, hydrolyze for 22 h at 110 °C under nitrogen protection conditions to completely hydrolyze the protein, and measure the concentration of amino acids in the hydrolyzed product by OPA method.

[0055] The protein powder selected here can be soybean protein isolate, corn gluten powder, wheat gluten powder, or fish scale collagen.

Embodiment 3

[0056] The preparation of embodiment 3 lipopeptide surfactants

[0057] Get 20ml of one of the protein hydrolyzates prepared in the above-mentioned examples 1 and 2, put it into a reactor with a temperature control jacket, and drip the total molar amount of free amino groups with a constant current pump under 800rpm magnetic stirring. 1.5 times of the acylating reagent was added dropwise within 1 hour. During this process, an automatic potentiometric titrator was used to maintain the reaction at a constant pH value of 9.5±0.05, and the reaction temperature was controlled at 4°C. After the dropwise addition of the acylating reagent was completed, the reaction temperature was raised to 50° C., and the reaction was continued for 2 h before ending.

[0058] The acylating reagents selected here include: oleoyl chloride, lauroyl chloride, decanoyl chloride, or benzoyl chloride.

[0059] The acylation rate of lipopeptide surfactants was determined by OPA method.

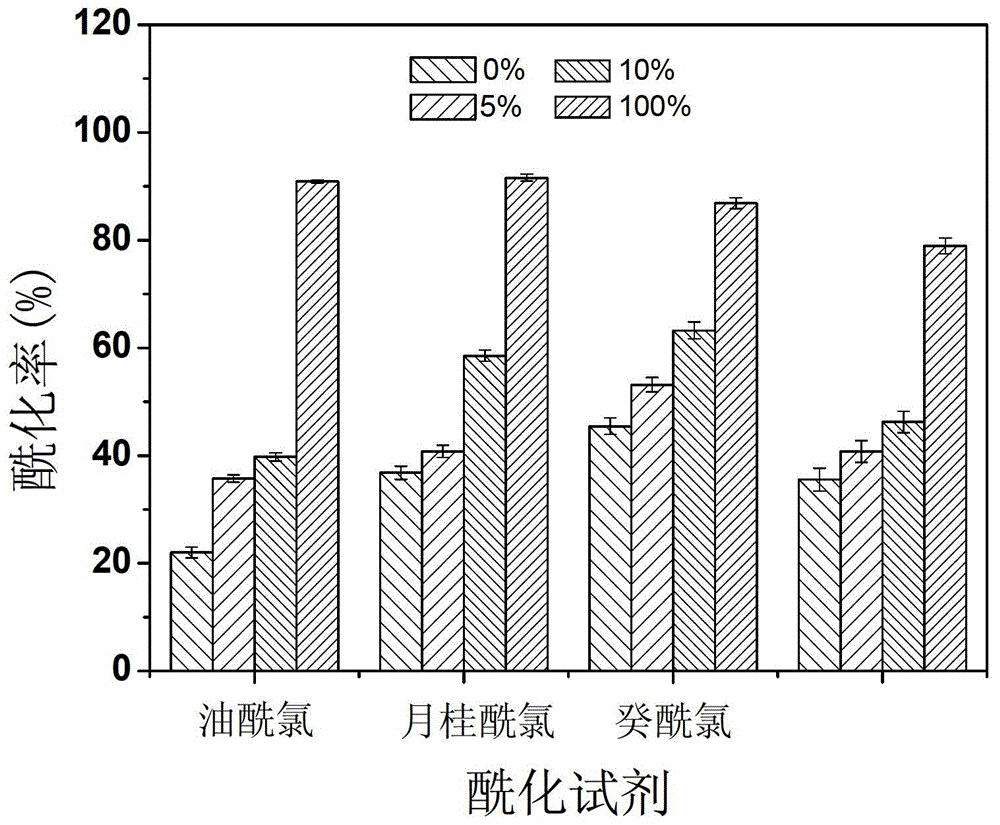

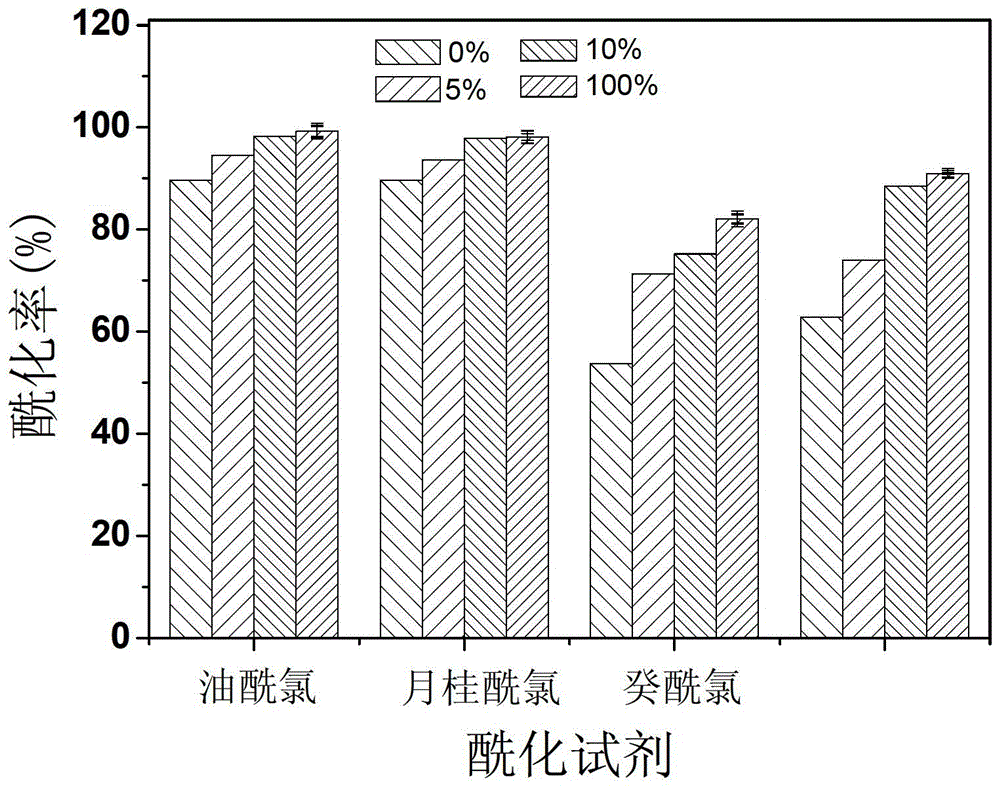

[0060] figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com